Table of contents

Table of contents- How to Achieve Greater Operational Efficiency in Your Business

- What is Operational Efficiency?

- The Evolution of the Supply Chain and Increasing Complexity

- KPIs for Measuring Operational Efficiency

- The operational excellence model in stock management

- Four Steps to Operational Efficiency

- How Desigual Improved Its Operational Efficiency: -27% Stock with +4% Availability Using Slimstock

- The Relationship Between Operational Efficiency and Stock Management

- Operational Efficiency Across Different Links in the Supply Chain

- Operational Efficiency: Key to Competitiveness

- FAQs on Operational Efficiency

Overview

Operational efficiency means maximizing productivity and reducing costs (doing more with less) by optimizing resources and processes. Key strategies involve strategic inventory management, monitoring KPIs like stock availability and turnover and a structured approach including assortment management, defining stock rules and optimizing order quantities (EOQ) and lead times. Its application varies across the supply chain from retail to manufacturing and distribution.

What is Operational Efficiency?

Operational efficiency is a company’s ability to do more with less: optimising resources, processes, and time to maximise productivity and reduce costs, all without compromising the quality of products or services. This involves eliminating anything that doesn’t add value, cutting waste, and leveraging technology to make everything more agile and effective.

This concept can vary depending on the area of the business. For example, in retail, the focus is on dynamic inventory management and providing a better customer experience. In distribution, it’s about logistics accuracy and route optimisation. In manufacturing, the priority is to boost productivity while maintaining strict quality control.

Achieving greater operational efficiency not only improves financial outcomes but also enables businesses to adapt to changing customer demands and position themselves as leaders in their industry.

In this article, we’ll explore the challenges businesses face and highlight key strategies to achieve operational efficiency throughout the supply chain.

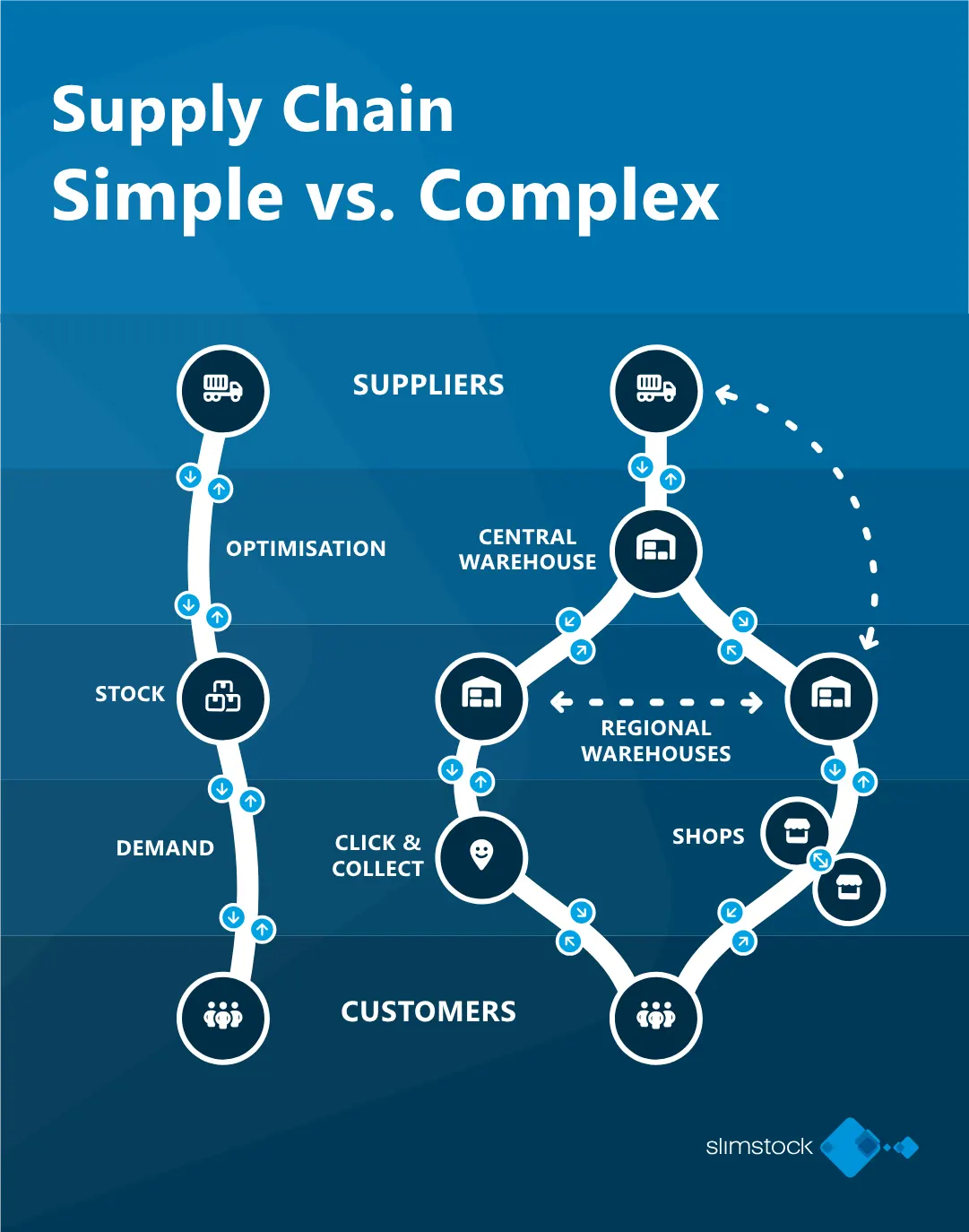

The Evolution of the Supply Chain and Increasing Complexity

First and foremost, it’s important to recognise that achieving operational efficiency becomes more challenging as a business grows and evolves. In its early stages, most businesses operate with a simple, linear supply chain model, often managing stock from a single central warehouse.

However, as the company expands, the supply chain becomes more complex, involving multiple storage points, distribution centres, and regional offices. Achieving operational efficiency in this environment requires meticulous planning and careful management of inventory flows and logistics networks.

To meet demand within a complex supply chain, businesses must implement well-defined stock management strategies tailored to each level. Operational excellence in this context involves maintaining a comprehensive view of inventory and logistics, ensuring every part of the network aligns with customer needs and the company’s commercial goals.

KPIs for Measuring Operational Efficiency

Key Performance Indicators (KPIs) are vital for measuring the performance of the supply chain and inventory management. Achieving operational efficiency requires defining and continuously monitoring these metrics to evaluate processes and make informed decisions for ongoing improvement. Below are some of the most relevant KPIs in this context:

1. Stock Availability

This KPI measures how effectively a company meets customer demand—essentially, the percentage of times a product is available when needed. High availability reflects good planning and inventory management, boosting customer trust and enhancing the shopping experience.

2. Inventory Turnover

Inventory Turnover indicates how quickly products are sold and restocked. High turnover suggests strong demand and efficient management, while reducing the risk of obsolescence. However, balance is key: overly high turnover may indicate insufficient inventory, while low turnover could mean excess stock and unnecessary costs.

3. Inventory Costs

This KPI includes all expenses associated with holding and managing stock, such as storage, insurance, and depreciation. Efficiently managing these costs helps the company become more profitable and resourceful.

4. OTIF (On Time In Full)

This KPI assesses whether customer orders are delivered on time and without errors. Delivering as promised builds trust and enhances the perception of quality. Failures in this area highlight process gaps that need addressing to remove obstacles and improve overall efficiency.

Have a look at the complete article on On Time in Full (OTIF) to dive deeper into this KPI.

In summary, the key to efficient operations lies in measuring, understanding, and acting on these KPIs. It’s about leveraging information to make smart decisions, drive continuous improvement, and keep customers satisfied.

The operational excellence model in stock management

Deciding between a “push” or “pull” inventory management model is crucial for supply chain success and operational efficiency.

- In a push model, inventory is proactively distributed to branches in anticipation of demand.

- In a pull model, inventory movement is triggered by actual orders or real demand signals, reducing the need for excess stock.

An operational excellence model in inventory management is often a customized combination of both approaches, where inventory is dynamically adjusted to the specific needs of each point in the supply chain. By tailoring this combination to the actual requirements of each location, companies achieve superior efficiency and optimize their resources.

Four Steps to Operational Efficiency

To optimise the supply chain and manage inventory effectively, it’s essential to follow a structured process that enables continuous improvement. Here’s how to get started:

Step 1 – Assortment Management

Identify the most valuable products and focus efforts on these key items, reducing complexity and maintenance costs.

Step 2 – Implementing Efficient Stock Management Rules

Stock management rules based on demand, profitability, and sales frequency criteria ensure that only key products remain in inventory. This approach avoids unnecessary storage issues and allows for a more agile response to market demand.

In this context, businesses should avoid applying a one-size-fits-all approach to all products in stock. Differentiating service levels enables the management of each product according to its strategic importance and impact on the business:

- High-turnover, high-profit products: These should maintain a high service level to ensure continuous availability and prevent stockouts.

- Low-turnover or seasonal products: These can have a lower service level, reducing costs and aligning with their demand cycle.

Step 3 – Managing Different Stages of the Product Lifecycle

Every item follows its unique product lifecycle, from market introduction to decline and eventual discontinuation. Each stage requires distinct stock management strategies:

- Introduction phase: Businesses take risks and focus on market positioning.

- Maturity phase: The focus shifts to cost optimisation.

- Decline phase: The priority is to clear inventory and minimise losses.

Step 4 – Using EOQ to Optimise Orders and Reduce Costs

Economic Order Quantity (EOQ) is a key tool for optimising order sizes and minimising inventory costs. By balancing ordering costs and holding costs, companies can reduce expenses while maintaining product availability.

We suggest you take a look at this article on the Economic Order Quantity (EOQ) to learn more about this topic.

Step 5 – Managing Lead Times

Reducing lead times contributes to greater supply chain efficiency and better responsiveness to customer demand. Achieving operational excellence in this area requires analysing internal processes to minimise delays that could impact inventory availability.

How Desigual Improved Its Operational Efficiency: -27% Stock with +4% Availability Using Slimstock

Desigual has significantly enhanced its operational efficiency with the help of Slimstock. By implementing Slim4, the brand reduced its stock levels by 27% while increasing product availability by 4%. This tool has been instrumental in optimising inventory management, addressing the specific needs of the fashion sector, such as short product lifecycles and seasonal sales.

Moreover, it has provided a more strategic and agile business perspective, enabling teams to focus on higher-value tasks, ultimately boosting their competitiveness in the global market.

The Relationship Between Operational Efficiency and Stock Management

To achieve greater operational efficiency, it’s crucial to adopt a systematic approach to stock management. This involves implementing well-defined processes that eliminate waste, optimise workflows, and ultimately enable better decision-making.

One of the biggest challenges for businesses, especially for operations departments, is the constant need to resolve operational issues – a practice often referred to as “firefighting”. This reactive management style is not only inefficient but can also be exhausting for operations teams. A more proactive approach, on the other hand, provides a preventive and strategic framework that allows the operations department to address problems before they arise, maintaining control over stock flows and improving the experience for both the team and customers.

Where to Start?

To put the concepts we’ve discussed into practice within a business, it’s advisable to start with a small group of high-relevance products to test the benefits, and then gradually expand the approach to the entire range. This method allows companies to focus on those products that contribute most to their profit margins, optimising processes in a controlled and gradual manner.

Here are some ideas to get you started:

- Improve data quality: Ensure that your systems accurately reflect the real stock levels. If the data is incorrect, it will be impossible to improve efficiency.

- Establish clear stock rules: Create data-driven policies to avoid reactive decision-making and optimise the availability of key products.

- Progressive optimisation: Start with the products that contribute most to the margin to demonstrate the benefits of operational efficiency and build internal support for large-scale implementation.

Operational Efficiency Across Different Links in the Supply Chain

So far, we’ve looked at the general aspects of operational efficiency. However, the operations of each company can vary significantly depending on factors such as the industry and its role in the supply chain. This means there are key differences depending on whether a company is a manufacturer, distributor, or retailer. Let’s take a closer look at these differences.

Operational Efficiency in Manufacturing Companies

Operational efficiency in the manufacturing sector focuses on maximising productivity, optimising resource use, and reducing costs across the entire production chain. For a manufacturing company, operational efficiency means achieving the optimal balance between quality, production speed, and the control of raw materials and finished product inventories.

Optimising the Production Process

Operational efficiency in manufacturing starts with optimising the production processes. This includes the implementation of methodologies such as Lean Manufacturing and Six Sigma, which help to reduce waste, minimise errors, and maximise efficiency at each stage of production. These methodologies enable companies to identify and eliminate activities that do not add value, thereby improving overall plant productivity.

Management of Raw Materials and Components Inventories

In manufacturing, efficient management of raw materials and component inventories is crucial to avoid production disruptions. Manufacturing companies may sometimes implement Just-In-Time (JIT) inventory systems, which ensure that raw materials are delivered exactly when needed, reducing storage and associated costs.

Effective inventory management ensures that the necessary materials are always available to maintain production flow without stopping the lines or accumulating excessive stock.

Automation in the Production Line

To improve efficiency, manufacturing companies often implement advanced technologies and automation systems in their production lines. These tools not only speed up processes but also ensure greater accuracy and consistency in manufacturing.

The modern industry has introduced tools such as collaborative robots, real-time monitoring systems, and IoT technology, which allow manufacturers to manage each stage of production more precisely and adapt quickly to changes in demand or product design.

Quality Control and Defect Management

Quality management is essential in manufacturing to ensure that products meet customer standards and expectations. Manufacturers implement stringent quality controls at each production stage to identify and correct defects before the product reaches the end customer. This practice not only reduces waste and reprocessing costs but also ensures a reputation for quality and reliability.

Production Planning and Scheduling

To achieve operational efficiency, manufacturing companies need to plan and schedule production based on demand, resource usage, and plant capacity. This includes shift scheduling, production planning according to sales forecasts, and managing downtime for preventive maintenance. Good planning helps avoid disruptions, optimises machinery use, and ensures smooth, continuous production.

Operational Efficiency in Retail

Operational efficiency in retail is characterised by a strong focus on the end customer, which requires dynamic, consumer-oriented management. Inventory management is key to maintaining smooth operations, reducing costs, and enhancing customer satisfaction.

Customer-Focused Inventory Management

Unlike manufacturers and distributors, retailers must maintain inventories that are closely aligned with the demand of the end consumer. In retail, demand variability is constant, which forces businesses to continuously monitor trends and adjust stock levels at each point of sale based on customer needs. This means responding quickly and accurately to changes in demand, which can involve frequent restocking or redistributing products to specific stores based on local buying patterns.

Restocking and Agility in Distribution

Proximity to the end customer requires a much more agile and precise restocking process than in other parts of the supply chain. Unlike manufacturing, where the focus is typically on producing large quantities at the lowest cost, retail needs flexibility and speed to respond to real-time demand. Retailers, especially those with multiple outlets, must coordinate their inventory between stores, distribution centres, and warehouses continuously to avoid both surplus and stockouts at each location.

Management of Perishable Products

In retail, especially in sectors like food, managing shelf life and minimising waste is a critical operational difference compared to manufacturing and distribution. Products must be available at the right time to maximise their freshness and shelf life for the consumer. This requires efficient management of expiration dates and local inventory control, optimising product rotation to minimise losses due to obsolescence.

Technology for Omnichannel Retail

Digitalisation and the rise of omnichannel retail are two key factors that cannot be overlooked when discussing operational efficiency in retail. Modern retail integrates multiple sales channels and customer touchpoints, such as online sales, click-and-collect, or in-store shipping. This demands highly synchronised operations across these channels to deliver a seamless shopping experience. In this context, technology enables inventory visibility and optimises product flow based on the customer’s preferred shopping channel.

Operational Efficiency in Distribution Companies

Operational efficiency in the distribution sector has its own unique characteristics that set it apart from retail and manufacturing. For a distribution company, the focus is on optimising the flow of products between manufacturers and retailers, ensuring that inventory is managed swiftly and accurately to meet the demands of both sides of the supply chain.

Inventory Management in Large Volumes

Unlike retail, where the focus is on presenting products to the end customer, distribution companies handle large volumes of inventory intended for multiple clients across different locations. Operational efficiency in distribution requires robust systems to manage large-scale inventories, ensuring accuracy in the management of quantities, locations, and shipping schedules.

Optimisation of Routes and Transport Logistics

Logistics efficiency is crucial for distribution companies, as their operations depend on fast and effective deliveries to retailers, secondary distributors, or end customers in geographically dispersed areas. Unlike retail businesses, which focus on the in-store customer experience, distributors need to optimise delivery routes and schedules to reduce transport costs and maximise punctuality.

Warehouse Automation and Efficient Picking

Given that distribution companies typically manage much larger inventory volumes than retailers, warehouse automation is a key strategy to improve operational efficiency. Implementing automated picking systems, along with smart storage technologies, allows distributors to process orders quickly and with minimal human intervention, reducing errors and preparation times.

Minimisation of Cycle Times

Distribution companies must carefully manage their cycle times, as any delay can affect not only their relationship with retailers but also with manufacturers. The cycle time in distribution refers to the total time it takes from receiving products into the warehouse to final delivery. An efficient distribution cycle involves minimising handling, storage, and transport times.

Managing Supplier and Customer Relationships (B2B)

Unlike retailers, who operate in a B2C environment, distribution companies primarily manage B2B relationships, working closely with both manufacturers and retailers. Effective management of these relationships is essential to ensure a continuous flow of products and maintain an adequate service level. Distributors need to coordinate efficiently with suppliers in terms of demand forecasting, production scheduling, and delivery times, while ensuring that retailers receive products in line with their needs.

Operational Efficiency: Key to Competitiveness

In today’s highly competitive environment, operational efficiency is essential for any company aiming to lead its respective sector. Regardless of the industry or position within the supply chain, achieving excellence in operations is the only way to control costs while delivering the best possible service to customers.

FAQs on Operational Efficiency

What is operational efficiency?

Operational efficiency refers to a company’s ability to optimise resources, reduce costs, and maximise productivity in its processes. By minimising waste and improving workflow, businesses can deliver high-quality products or services in a quick and cost-effective manner, resulting in a more competitive operation focused on meeting customer needs.

How is operational efficiency achieved?

Operational efficiency is achieved through process optimisation, waste reduction, and the smart use of resources. This involves implementing advanced technology, automating repetitive tasks, and applying methodologies like Lean or Six Sigma to improve quality and reduce errors. Additionally, effective planning, continuous performance monitoring, and adapting to market demands are essential to maintain an agile and competitive operation.

What role does technology play in achieving operational efficiency?

Technology is key to achieving operational efficiency as it enables process automation, improves accuracy, and reduces execution times. Tools such as data analytics, artificial intelligence, and the Internet of Things (IoT) facilitate real-time monitoring and data-driven decision-making. This optimises resource usage, reduces errors, and allows for a swift response to changes in demand, ultimately improving productivity and reducing costs.

What challenges do businesses face in achieving operational efficiency?

Businesses face several challenges in achieving operational efficiency, including resistance to organisational change, a lack of training in new technologies and processes, and the need for investment in infrastructure and technological tools. Additionally, the complexity of coordination between departments, managing real-time data, and adapting to constant changes in demand can also hinder the ability to achieve a truly optimised and competitive operation.