Table of contents

Table of contents- Is OTIF The Right Way to Measure Availability?

- What is OTIF and can it help your business perform better?

- OTIF Vs. Availability

- How to calculate OTIF

- How can we use OTIF?

- How can we use OTIF to measure supplier performance?

- What’s a good OTIF target?

- What are the benefits of OTIF?

- What are the limitations of On Time, In Full (OTIF)?

- How do we approach the OTIF conundrum at Slimstock?

- How can you use OTIF to improve availability & supplier performance?

- Let’s dive a little deeper into each of these points…

- OTIF (on-time in-full) takeaways

- OTIF FAQS

What is OTIF and can it help your business perform better?

To answer this question effectively, let’s look back at the groundings of OTIF (or ‘On Time, In Full’) and how it helped improve one the world’s biggest businesses.

Walmart, a company that knows a little something about supply chain management set about improving their supply chain. The intention was to track supplier performance, create improvements in-store and increase customer satisfaction.

In its most simplistic sense, On Time in Full (OTIF) is a supply chain metric. And its sole purpose is to measure a company’s ability to fulfil customer orders.

Perfect then as a legacy of Sam Walton, Walmart founder, who’s quoted as stating “There is only one boss. The customer. And he can fire everybody in the company from the chairman down, simply by taking their business elsewhere.”

Creating a system of analysis based on a companies’ ability to do just this, seems like a thoroughly sensible move.

If supply chain excellence is on your agenda, On Time in Full (OTIF) can reveal a lot of detail about your supply chain performance you’d otherwise miss.

It can tell you how well you’re satisfying your customers. Whether your suppliers are delivering as promised. And even if you’re doing your internal supply chain justice.

And yet, I’d guess there’s a huge number of businesses that have never thought about measuring OTIF in the supply chain.

OTIF Vs. Availability

Every business in the world wants just the right amount of availability.

As we touched on in this article, there’s a sweet spot with this. You never want too much, lest you fall into excess stock worries and obsolescence.

And you never want to be caught short either, or missed sales opportunities and unhappy customers will soon follow.

But measuring availability’s a difficult practice to master.

Firstly, OTIF & availability are related. But they are not the same.

Sure, high availability levels will probably help you to attain a strong OTIF. But not if your small number of availability issues impact your most important product lines!

The next challenge is that availability means different things to different people.

Do you look at OTIF? Are fulfilment rates a good benchmark? What’s the best way to measure the availability and why is there such confusion over a relatively simple question?

The answer’s not so straightforward. Primarily due to a lack of standard OTIF definition.

Thus, whenever there is a conversation about product availability, everyone is speaking in different languages.

Think about your own business.

What does ’on time’ mean to your logistics provider or supplier? What does it mean to your Finance or supply chain department?

And how misaligned are those two dates?

What about the “In Full” part? Do you have a consensus as to what classes as ‘completed’ orders?

This is before we get onto the differences between specific suppliers and manufacturers, and who we hold to account when the “On Time” part of this deviates from what has been agreed.

Most people will agree that an under delivery is a problem. But what about an over delivery?

Receiving more stock that agreed is clearly a failure in process. But how should we account for this?

How to calculate OTIF

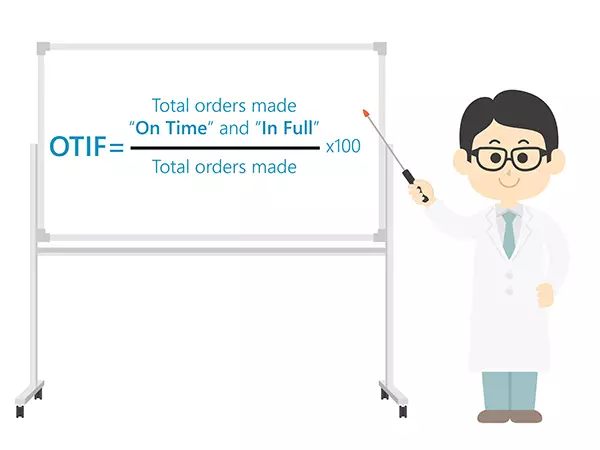

On paper, the OTIF formula is pretty simple.

We take the total number of orders that were made on time and were complete and then divide this by the total number of orders.

In its more simplistic form, On-time (OT) simply assesses whether your outgoing orders have arrived on time.

The In Full (IF) part looks at whether the correct volume was received.

Measuring both components as a whole then analyses how satisfied your customers are, assuming the orders are in good condition once they arrive at their destination.

How can we use OTIF?

Throughout this article, we are going to talk about OTIF from two perspectives:

Inbound OTIF – This is where we track the supplier’s OTIF against their purchase orders.

Outbound OTIF – This where we measure OTIF on your own outbound orders to your final customers.

How can we use OTIF to measure supplier performance?

OTIF can also be a powerful supplier benchmark.

After all, we can use ON Time In Full (OTIF) to explore some important questions:

- Are your suppliers living up to the promises they gave you in the first place?

- Are they damaging your reputation and relationships with customers?

- Do you have data to back up your misgivings?

- And can you present this back to those holding the purse strings?

Not to throw too many acronyms at you, but OTIF KPIs are fantastic tools to take theoretical practise and relate it to real life. They allow you to look at cold hard facts and improve business performance almost instantly.

What’s a good OTIF target?

You’d think, like a lot of things, 100% is the number to aim for when setting your On Time In Full OTIF target. Yet, in practice, it’s almost unattainable to reach 100%. (Or rather, it would be super expensive to try!)

Especially when you think about the sheer weight of opportunities for outside influence to affect the supply chain.

This is more evident with events like COVID or Brexit.

But it’s something to consider in a harmonious environment too.

To exemplify this, Walmart’s initial Outbound OTIF calculation was 75%. But the key metric they looked at was for improvement. And from that initial barometer, they’ve managed to increase their score up to 87%. This is a long way from perfect, but a notable increase nonetheless.

What are the benefits of OTIF?

There are plenty of scenarios where measuring OTIF can help your business. Here are just a few examples:

What if half of your order goes missing? What if you get double the volume you agreed?

What if you get the shipment 2 weeks earlier than expected? Sure, sometimes that’s good news. Unless of course you simply don’t have the warehouse space to accommodate an instant increase in stock.

What if their delivery’s late? How long can you dampen your customers’ expectations before they shop elsewhere? Not long, I’d guess.

This is where the On Time, In Full (OTIF) metric comes into its own.

Often, we can see the issue with late or missed orders immediately.

Although you might hear the operations team grumble about having to find space in the warehouse for an unexpected order, this is quickly forgotten.

The sales team may be a little less forgiving in the event of a stockout caused by a supplier’s missed order.

But even then, you need the tools to track if this was a one-time mistake or a whether the guilty party is a serial offender.

What are the limitations of On Time, In Full (OTIF)?

You would think that OTIF would do exactly what it says on the tin.

And, to some extent, you would be right.

However, we have to consider our original challenge.

Availability, completed orders… These simple concepts mean different things to different people.

The other challenge is in capturing the nuances and complexities of your operation.

For example, how do you calculate the ‘On Time’ metric for an item that is already on back order? After all, back orders can never be on time. Otherwise, they would have been delivered already!

What about where supplier orders are spread over several weeks or months? Should you consider each delivery individually or only when the final load arrives?

Consequently, tracking this metric effectively is often easier said than done!

How do we approach the OTIF conundrum at Slimstock?

To gain a good impression of both your suppliers’ performance & your service to customers, you need data points you can trust.

Let’s start with your customers…

We want to achieve a transparent picture of whether or not we are meeting our customer’s needs.

And for this, we can explore:

Current availability – How much stock do we currently have on hand? And where in the chain is this stock held?

Calculated service levels – If we do go out of stock, how much of the anticipated demand will we miss? We can also review this retrospectively and explore the impact of past stockouts.

And what about monitoring supplier performance…

Supplier parameters have a huge impact on when we order, & how much we order.

Therefore, the question we want to answer here is: Are our suppliers doing what they promised?

And for this, we need to understand the following:

Lead-time variation – To what extent did the ‘real’ lead-time differ from the lead time agreed with the supplier?

How can you use OTIF to improve availability & supplier performance?

As with all metrics, there is little point in tracking them unless you are going to take action.

There are several ways to improve both the availability you offer your customers and the service you receive from suppliers.

But here are the 5 steps you should focus on to improve your OTIF metrics:

- Ensure total clarity over all KPIs

- Collect data consistently

- Set realistic targets

- Detect issues & take action early

- Compare & contrast with your other KPIs

- Remain inquisitive

Let’s dive a little deeper into each of these points…

Ensure total clarity over all KPIs

The very first starting block must be the corroboration of measurement. It’s only natural that those from different businesses have varying methods of analytics.

However, it’s also pretty common for different teams within the same business to have a different perspective on what the metrics really mean.

Regardless of what variation of On Time In Full (OTIF) you use or if use a different metric entirely, everyone needs to understand & agree on how the metric is calculated.

Collect data consistently

By setting up properly, you’ll find the incremental improvement far easier to realise. Simply, you must all measure in the same way. Otherwise, you might as well not begin in the first place.

Set realistic targets

Your performance probably won’t change much if you carry on doing the same things you have always done. To move forward & deliver tangible results you will need to deploy new tactics & strategies.

OTIF, Current availability, Calculated service levels & lead-time variation are all useful in measuring this performance improvement trajectory.

However, you first need to have a clear understanding of where you are heading. If your ambitions are too lofty or misaligned with your overall business goals, you might be left high & dry.

Top tip: If you would like to read more about how to establish effective goals, you can read our guide to S&OP. In this roadmap, we explore how you can translate your strategy into an actionable tactical plan.

Detect issues & take action early

You have the data; everyone understands the goals & you have a plan in place. But now what?

The problem with almost all availability metrics is that by the time you notice you have a problem, it’s often far too late. Therefore, you need to be proactive in detecting potential issues before they hit your business.

What issues do you need to watch out for?

When it comes to hitting customer On Time In Full targets, there is only one thing we need to worry about:

Do we have sufficient availability to cover anticipated demand until the inventory can be replenished?

The action we chose to take depends on the situation.

Perhaps we could bring the next supplier replenishment order forward. We could even expedite the order and incur the additional cost of airfreight.

Either way, the sooner you can detect a shortfall, the more options you will have to rectify the issue.

But what about supplier OTIF?

This is a little trickier. After all, how do you know if your suppliers are going to let you down?

We could consider the supplier’s track record.

If they are perpetual offenders for late or incomplete orders, perhaps we could build in some buffer stock to protect the availability. But then again, why should we pay for a supplier’s poor performance?

Alternatively, we could try and work with suppliers.

Just by robustly thisKPI, we become better positioned to challenge performance issues head-on.

However, by sharing information about our future inventory requirements, the supplier may be better positioned to fulfil your order.

Furthermore, if the supplier can provide insights into their availability, this may help us detect shortfalls much earlier.

Compare & contrast with your other KPIs

Celebrating a great OTIF performance in isolation is fool’s gold.

You need to think about how OTIF works in conjunction with other analyses and how crucial they are to evaluating business performance. For example, realising you’re hitting a 95% OTIF performance is great.

But not if you’ve over-invested working capital or have a huge risk of obsolescence, which might massively hurt long-term business.

The other thing to mention here is how does your OTIF compare between different product groups?

If you have near perfect availability for your C-items, that’s great. But not if your A-items are performing poorly.

Remain inquisitive

Where your OTIF delivery or availability performance falls short, you need to ask the question: WHY?

Is it because your tactics are wrong? Are other factors impacting your results that you had not considered? Or are your original goals no longer relevant?

And this is not just about identifying areas of under-performance. We also want to look for where we have far exceeded OTIF goals. Perhaps we could apply these same tactics to other areas of the operation.

After all, the whole point of setting goals is to challenge the status quo! And OTIF is no exception.

OTIF (on-time in-full) takeaways

In this article, we have explored the origins of OTIF, its benefits, limitations and how you can use this metric to make a positive impact on your business.

Introduction and Background:

- OTIF is a supply chain metric designed to measure a company’s ability to fulfill customer orders.

- It originated from Walmart’s endeavor to improve supply chain performance, boost in-store availability, and enhance customer satisfaction.

- The foundation of OTIF is based on Walmart founder, Sam Walton’s philosophy, emphasizing the centrality of the customer.

Difference between OTIF and Availability:

- Availability concerns having the right stock level. High availability can lead to strong OTIF, but problems arise if availability issues impact significant product lines.

- OTIF and availability are related but distinct, with differing definitions across various stakeholders.

Understanding OTIF:

- On-Time: Reflects whether orders arrived when expected.

- In Full: Evaluates if the correct volume was delivered.

- Inbound OTIF: Tracks supplier performance.

- Outbound OTIF: Measures deliveries to end customers.

Benefits of OTIF:

- Helps identify if orders are late, incomplete, over-delivered, or early.

- Aids in detecting if such events are recurrent or isolated incidents.

Limitations of OTIF:

- Vague definitions and interpretations of ‘availability’ and ‘completed orders.’

- Capturing complex nuances, like accounting for back orders or spread-out supplier orders, can be challenging.

Approaching the OTIF Challenge:

- For Customers: Focus on current availability and calculated service levels.

- For Supplier Performance: Track real lead-time against agreed lead-time.

Improving OTIF Metrics:

- Ensure clarity and agreement on KPIs.

- Consistently collect data.

- Set achievable targets.

- Act early on potential issues.

- Continuously compare with other KPIs.

- Stay curious and question both under-performances and over-performances.

Final Takeaway:

- OTIF is an effective tool to streamline supply chain operations, align various departments, and optimize customer satisfaction. While it’s valuable, it’s essential to balance it with other KPIs and keep adapting strategies for continuous improvement.

OTIF FAQS

What is OTIF?

OTIF is a performance metric used by businesses to measure their supply chain efficiency. It refers to the percentage of orders that are delivered on time and in full.

Why is OTIF important?

OTIF is important because it affects a company’s bottom line. Late or incomplete deliveries can lead to lost sales, increased costs, and damage to a company’s reputation. Measuring OTIF helps companies identify areas for improvement in their supply chain operations.

How is OTIF calculated?

OTIF is calculated as a percentage of orders that are delivered on the requested delivery date and in the quantity requested by the customer. The formula for OTIF is: (Number of orders delivered on time and in full / Total number of orders) x 100.

What is considered a good OTIF score?

A good OTIF score is generally considered to be 95% or higher. However, the acceptable OTIF score may vary depending on the industry and customer requirements.

What are some common causes of low OTIF scores?

Common causes of low OTIF scores include poor communication between suppliers and customers, inaccurate demand forecasting, production and logistics delays, inadequate inventory management, and transportation issues.