Table of contents

Table of contents- Reverse Logistics: What It Is and How to Turn It Into a Competitive Advantage

- What Is Reverse Logistics and Why Is It Important?

- Stages of Reverse Logistics

- Technology as an Ally in Reverse Logistics

- Reverse Logistics: Examples

- Common Scenarios in Reverse Logistics

- Benefits of Efficient Reverse Logistics

- Reverse Logistics: Best Practices

- Conclusion: Efficient Reverse Logistics as a Competitive Advantage

- FAQs About Reverse Logistics

Overview

Reverse logistics is the process of managing the flow of products from the end consumer back to the manufacturer or distributor, encompassing returns, repairs, recycling and disposal. While it presents operational challenges, effective management through stages like collection, sorting, refurbishment and technology-aided demand forecasting can transform it into a competitive advantage, leading to cost savings, increased revenue and enhanced brand image and customer loyalty.

Reverse logistics is a crucial aspect of the modern supply chain. This process, which includes product returns and waste management, presents operational challenges but also strategic opportunities to enhance efficiency and improve business outcomes.

In this article, we will delve into how effective management of reverse logistics can set your business apart from the competition.

What Is Reverse Logistics and Why Is It Important?

Reverse logistics refers to the flow of products from the end consumer back to the manufacturer or distributor. This process can involve returning defective items, handling commercial returns, recycling materials, or reusing components.

In an ideal world, there would be no need for this reverse flow. However, the reality is that a certain rate of product returns is unavoidable. Businesses that master this process not only reduce costs but also enhance customer satisfaction and strengthen their competitiveness.

Stages of Reverse Logistics

Let’s set the scene: the customer has purchased a product but decides it isn’t right for them and wants to return it. Naturally, this represents a setback for the seller. Once this has occurred, the goal is to recover the item as quickly as possible and, if feasible, resell it. Before reaching this stage of “resale,” there are several key phases to navigate.

Returns and Collection

The first phase involves accepting returns from customers. Depending on a company’s policy, this may include defective, damaged, or simply unwanted products. It is essential to have an efficient collection system or provide physical locations where customers can return items.

Sorting and Assessment

After receiving returned products, they need to be sorted and assessed. Some items may be reusable, others might require repairs or refurbishment, and some may no longer be usable and will need to be disposed of.

Refurbishment and Repair

At this stage, products that can be refurbished or repaired are restored to their optimal condition. This may include repairing components, cleaning, repackaging, or any other action necessary to make the product fit for resale. If the item can be restored and resold, this would typically be the final stage of reverse logistics. If not, additional steps are required.

Recycling and Material Reuse

For products that cannot be refurbished or have reached the end of their useful life, they are dismantled to recover valuable materials where possible. This promotes resource reuse, waste reduction, and supports a circular economy. If no valuable materials can be salvaged, the remaining items are recycled where feasible.

Disposal

Products or materials that cannot be recycled or reused must be disposed of in compliance with current regulations.

Technology as an Ally in Reverse Logistics

One of the greatest enablers of reverse logistics is technology. Advanced supply chain management systems work with two key concepts in reverse logistics management: demand forecasting and product coverage.

Demand Forecasting and Product Coverage

Demand forecasting provides accurate insights into future product needs, while product coverage indicates the amount of stock available in relation to projected demand. Together, these tools enable informed decisions regarding the handling of returned products.

For instance, if a returned item has high projected demand, it could be placed in picking locations to be quickly dispatched to another customer. If demand is low, the product could be stored in secondary locations or included in promotions. Additionally, robust technology systems can identify return patterns to reduce future errors.

The implementation of such technologies also allows data integration across departments, facilitating better coordination throughout the organisation. This collaboration is essential for maximising the value of reverse logistics.

Reverse Logistics: Examples

To illustrate how reverse logistics is applied in real-world scenarios, let’s review some notable examples – organised by industry – where reverse logistics adds value to business operations:

Fashion Industry

Global brands quickly remove poorly selling products from certain regions to redistribute them to stores where they are in higher demand. This approach maximises sales and reduces waste.

Appliances and Technology

Companies in this sector offer return programmes to recycle end-of-life products, recovering valuable materials such as metals and plastics. These initiatives simultaneously encourage customers to upgrade their devices.

Retail

Supermarket chains manage returns of non-perishable food items by redirecting them to food banks or donation programmes, yielding significant reputational benefits for the brand.

E-Commerce

E-commerce giants have implemented automated processes that make it easier for customers to return products, automatically sorting them for refurbishment or recycling depending on their condition. However, optimising your internal logistics processes is just as important to manage returns effectively. A well-structured intralogistics strategy can help streamline the reverse logistics flow, reduce costs, and improve overall efficiency.

These examples demonstrate how businesses can turn a challenge into a competitive advantage by adopting strategies tailored to their sector and specific needs.

Common Scenarios in Reverse Logistics

Companies face various challenges depending on their structure and logistics network. Below, we describe three typical scenarios:

Companies with a Single Warehouse

In companies operating with a single warehouse, returns are usually managed centrally. Integrating demand forecasting with the Warehouse Management System (WMS) can automate the sorting of returned products. For instance, high-turnover items can be placed in easily accessible areas, while low-demand items are allocated to less critical storage zones.

This automation not only streamlines inbound processes but also optimises space utilisation and reduces the likelihood of human error in the sorting and placement of returned products.

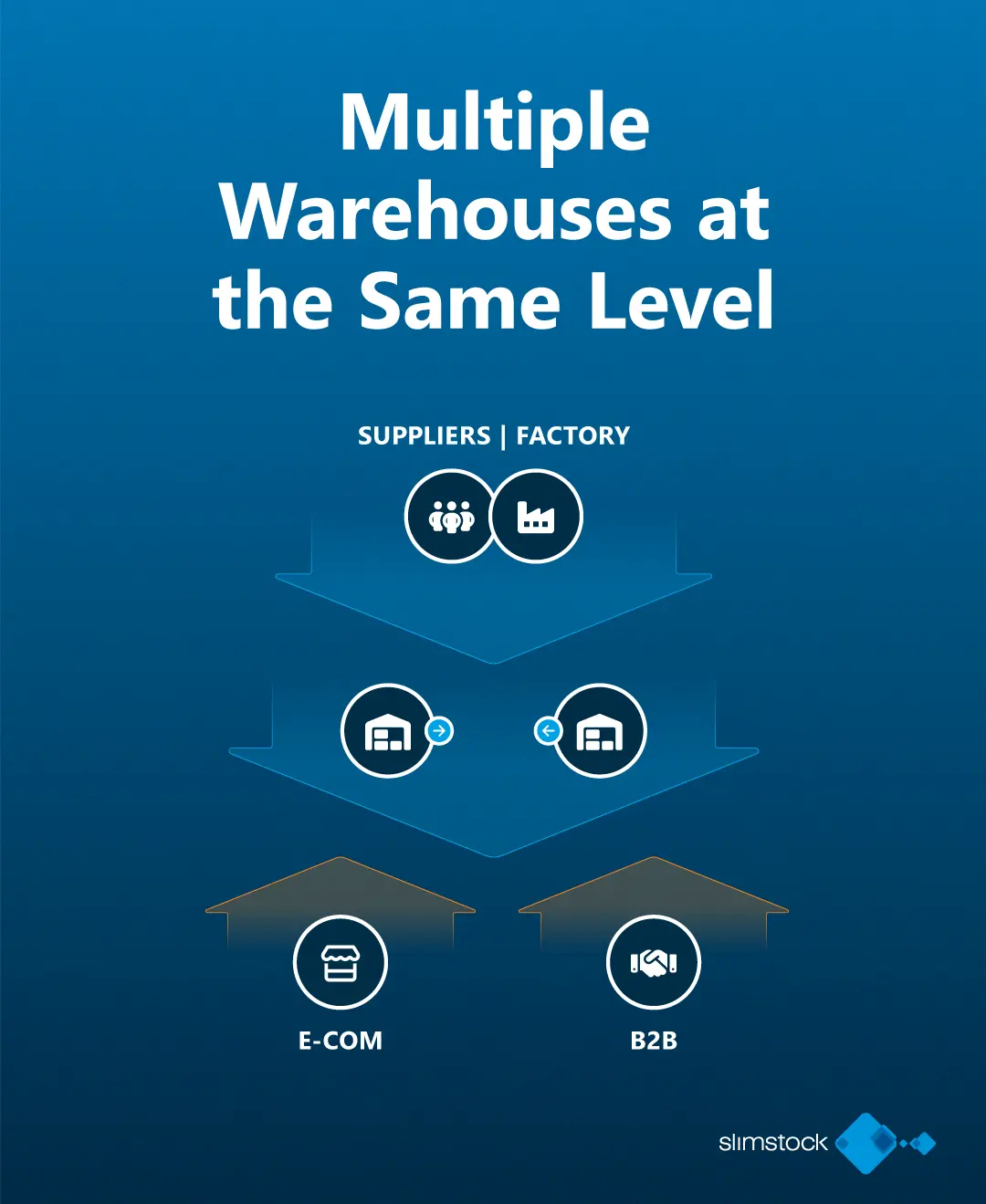

Companies with Multiple Warehouses at the Same Level

When multiple warehouses operate without hierarchy, reverse logistics faces the challenge of determining where to send returned products. An advanced forecasting system can direct returns to the warehouse with the highest likelihood of consumption, avoiding unnecessary transfer and storage costs.

For example, if a warehouse is expected to have high demand for certain products, it is more efficient to send returns there rather than to a less active location.

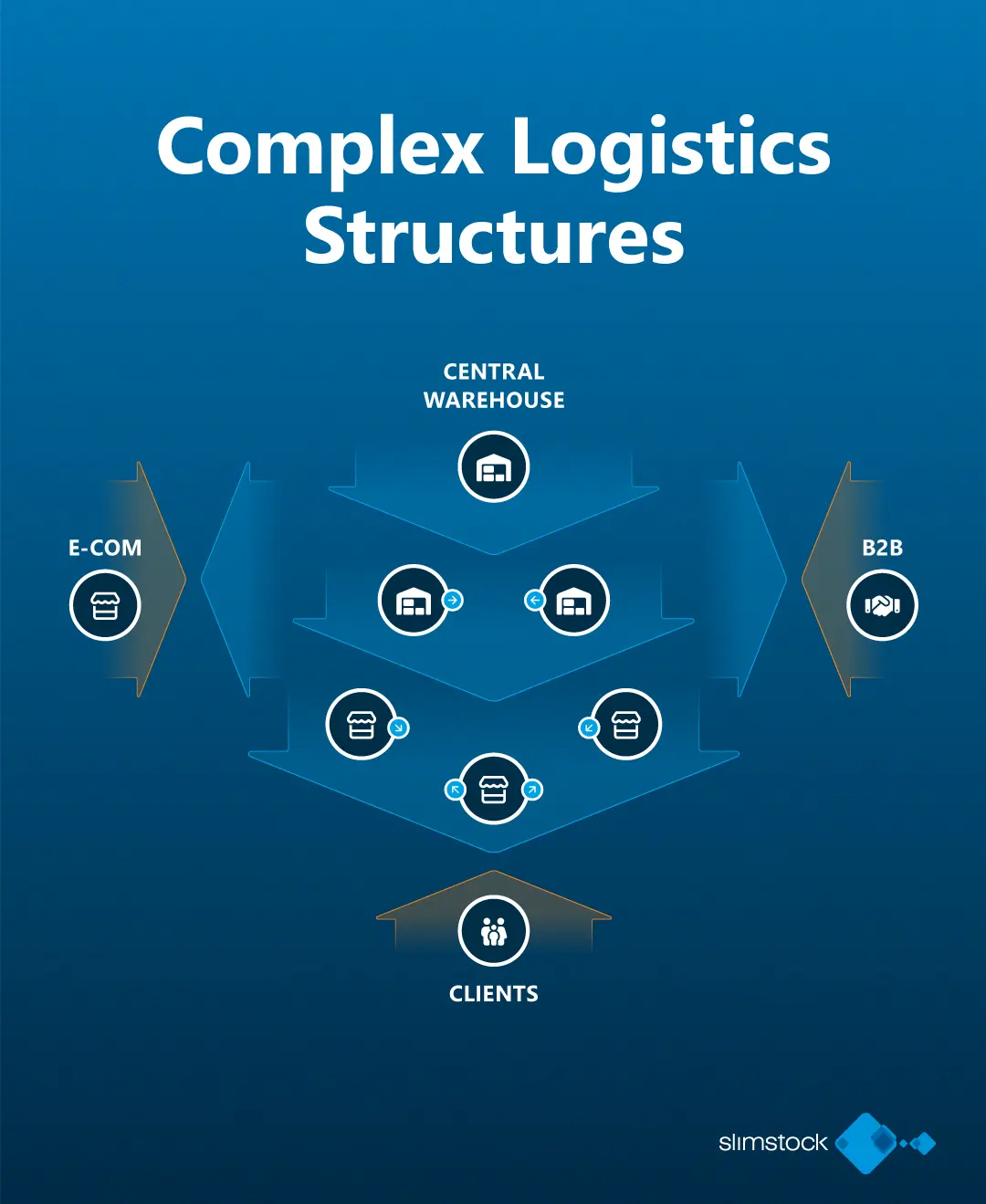

Complex Logistics Structures

In more sophisticated networks, with centralised warehouses, regional hubs, and direct sales points, returns may involve both horizontal and vertical movements. Here, companies can adopt a hybrid approach, managing customer returns while also enabling returns between nodes based on inventory needs.

For example, a product returned at one store could be relocated to another where it is more likely to sell, provided the technology system identifies this need promptly. This approach significantly reduces inventory downtime and improves product turnover.

Benefits of Efficient Reverse Logistics

Implementing an effective and efficient reverse logistics strategy offers multiple advantages for businesses:

- Cost savings: Reduces operational expenses by optimising return processes and minimising waste.

- Increased revenue: Enables value recovery through the resale, refurbishment, or recycling of returned products.

- Enhanced brand image: By adopting sustainable practices that prevent product wastage, companies reinforce their commitment to the environment and foster greater customer loyalty. Moreover, an efficient reverse logistics system also contributes to a better customer experience.

- Regulatory compliance: Simplifies adherence to regulations related to waste management and recycling.

- Improved operational efficiency: Integrating technology provides better visibility and control over returns, reducing errors and processing times.

Reverse Logistics: Best Practices

If not managed properly, reverse logistics can lead to high operational costs and challenges in inventory handling. However, with the right strategies, businesses can significantly mitigate these negative impacts and turn reverse logistics into a competitive advantage. How can this be achieved?

1. Optimising the Forward Flow of Goods

Efficient management of the forward flow (downstream) can significantly reduce returns. This includes the correct inventory allocation across warehouses and sales points, as well as the use of systems to automate supply and replenishment based on demand patterns.

Poor initial distribution is often one of the main triggers of returns, making it crucial to get this phase right. Regular analysis of inventory coverage and adjustments to minimise surpluses or shortages are equally important.

2. Analysing and Understanding Return Reasons

Recording and analysing the reasons behind returns can reveal valuable patterns. For instance, if a recurring issue is linked to a specific defect, the company can address it at the production or design stage.

This data can also be used to train the sales team and enhance customer communication, reducing returns caused by unmet expectations.

3. Product Segmentation

Classifying products based on their contribution to revenue and their volatility allows for prioritised efforts. High-revenue and high-volatility items typically account for the majority of returns, requiring closer monitoring.

Companies that have implemented effective segmentation strategies have managed to reduce returns by up to 20%, thanks to a more targeted approach to products that generate the most returns.

To reduce return rates and improve product lifecycle visibility, businesses can apply category management principles across their operations. This not only enhances alignment with customer needs but also contributes to more effective planning and supplier collaboration.

Conclusion: Efficient Reverse Logistics as a Competitive Advantage

As we’ve explored throughout this article, managing reverse logistics involves a certain level of complexity. It comprises various phases, some of which may rely on external providers, such as the handling of returns.

However, this complexity is a shared challenge across your industry. Therefore, by efficiently managing the entire process, the challenge of reverse logistics can be transformed into a competitive advantage. As we’ve seen, the potential benefits are substantial—from reducing operational costs to improving customer satisfaction and, consequently, strengthening your brand image.

FAQs About Reverse Logistics

What role does reverse logistics play in the circular economy?

Reverse logistics is fundamental to the circular economy, as it facilitates the reuse, repair, and recycling of products, closing the lifecycle of materials. It promotes sustainable practices that reduce environmental impact and resource waste.

What are the main challenges of reverse logistics?

One of the primary challenges of reverse logistics is the complexity of coordinating return flows across multiple points of origin and destination. This requires advanced technology to manage data and predict patterns effectively.

Additionally, the costs associated with the transportation and storage of returned products can be significant if processes are not optimised. Another key challenge is compliance with environmental and recycling regulations, which vary by region and can create legal and operational complications.

How does reverse logistics impact customer experience?

Efficient return management enhances the brand’s perception by offering fast and straightforward processes. This not only increases customer satisfaction but also fosters long-term loyalty.

What key performance indicators should be monitored in reverse logistics?

Some essential KPIs include:

- Return rate.

- Average processing time.

- Cost per return.

- Percentage of successfully refurbished or recycled products.