The Great Warehouse Space Squeeze

Your supply chain team will be getting used to shortages. The first shock was stock. The diminished deliveries and the lengthening lead times left your customers short-tempered and short-changed.

The next challenge was the clogging of cargo ports. With containers suddenly also hard to come by, the problem was only further exacerbated. And so, the shortage merry-go-round spun on, with little care for those on the ride.

But now we find ourselves in the middle of a new crisis.

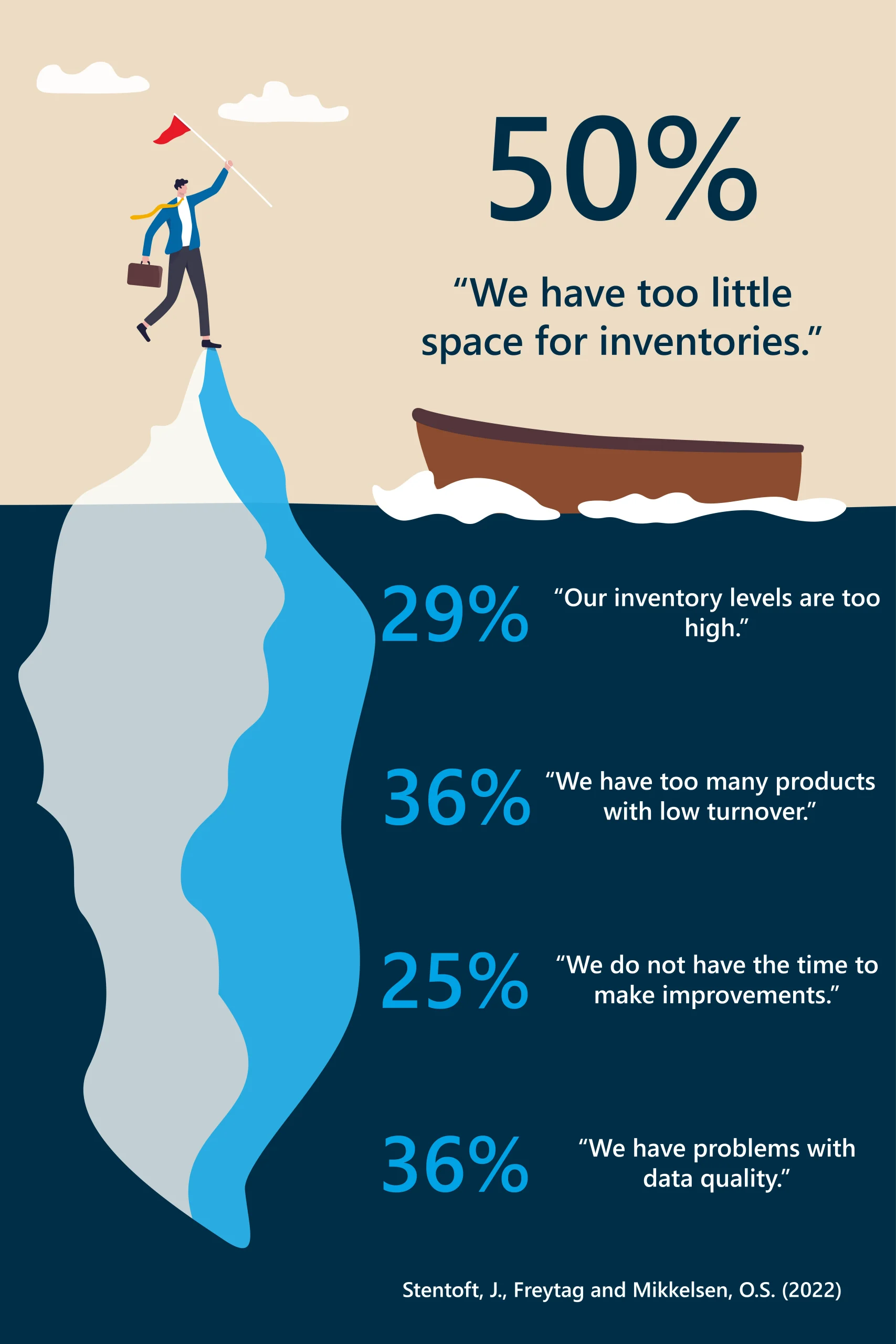

The fact that 50% of businesses pinpoint a shortage of warehouse space as their biggest challenge today tells its own story.

And multiplying soaring warehouse costs with the woes of a workforce shortfall, this isn’t something you can sweep under the carpet.

As the market pressures force supply chain teams to do more with less, what can you do to conquer the great warehouse space squeeze?

Learning lessons from the past

They often say history repeats itself. So, let’s look at some of the measures you may have taken tackle the turmoil of the last year or two.

It’s likely your business invested in stock for all the right reasons:

- To unlock economies of scale

- To protect your business against unreliable supplier lead times

- To mitigate demand volatility

- To hedge price increases

And these increased stock levels will no doubt have come in use. Especially in overcoming disruption from exterior factors. Of which, we’ve had a few in the recent years.

There was the Suarez canal crisis, huge disruption at ports, the ongoing headache (figurative and literal) from COVID, and a couple of Chinese New Year’s to cement the hangover.

But the world has since shifted. And there is no failure in admitting you may have been caught short.

Maybe, you failed to identify shifting demand pattern soon enough.

Or have you become so used to high stock levels, that you simply lost sight of just how much excess you’re carrying?

Either way, all your available warehouse space is full to the brim. Worse still, you may be sat on high levels of stock you now can’t sell.

Make no bones about it, your warehouse space is now exploding at the seams. And now you need to take action to sidestep this perilous situation.

That’s what this article will help you with. In this paper, we explore the practical steps you can take to tackle your warehouse space shortage.

A scan of the battlefield

Before you can resolve your issues, you first need to understand the scale of them.

Ever seen the size of an iceberg beneath the surface? Well, your lack of warehouse is just the tip.

So, let’s look at the bigger picture.

Problem #1: There isn’t enough warehouse space to go around

Warehouse occupancy rates are at an all-time high. That’s not just limited to you. It’s a problem many businesses are seeing.

In fact, in the US, warehouse vacancy rates dropped to 3.6%. But things are even worse in Europe. In the UK for example, warehouse vacancy rates dropped to an all-time nationwide low of just 3%.

Current demand for warehouse space massively outstrips supply. And so, finding suitable warehouse space is likely to be very difficult.

Problem #2: Warehouse costs are exploding

And so, with demand soaring, and supply crashing through the floor, naturally prices rise.

Which brings another challenge. Even if you can find warehouse space, can you afford it?

Average rent for warehouse space has increased by 10.4% in the last 12 months. For major logistics hubs, there are reports of this number being closer to 20%.

- And the outlook for 2023 isn’t much brighter.

This is more than a sudden price hike which might come back down. Warehouse costs have been increased at an exponential rate for years. In fact, they’ve increased by nearly 30% since 2011. And some analysts are bracing businesses for another 25% increase by 2026.

Problem #3: Even warehouse staff are in short supply

Let’s say you luck out.

You stroll back from work one day, and in the next neighbourhood you stumble upon a warehouse that’s local, the right size and cheap.

It’s perfect. What are the odds?

Now all you’ve got to do is staff it and you’re away.

But here enters problem #3.

At this current moment, 80% of businesses are suffering warehouse staff shortages.

Just getting stock to your brand spanking new warehouse could be a problem with over 60% of companies reporting a shortage of drivers.

A solution, a solution, my warehouse for a solution.

Now, there are probably lots of supply chain leaders reading this and thinking: “But Rich, a new warehouse was always on the cards!”

And good for you!

Sure, if you need additional warehouse space to support controlled strategic growth, that’s one thing. But a mad scramble to find a new facility because you have unexpectedly outgrown your existing capacity is a different problem indeed.

This paper was written for the latter in mind. But if you are one of the fortunate few that falls into the former category, worry not!

The tips, tactics, and strategies we will explore are equally relevant to you. In fact, they could save you from heartache and headaches further down the line.

So, what’s the solution?

If you can do more with the space you have, you have more space. That doesn’t mean reading a book about warehouse feng shui.

It means stocking the right products as an absolute necessity. And stocking the wrong products becomes the ultimate supply chain crime.

It means ordering stock at the right moment becomes an art form of agility and poise.

But most importantly, it means optimising your inventory to the right levels as a matter of life and death (at least from your company’s perspective).

Inventory gymnastics

It may be however, that neither agility nor poise have been at the top of your list recently. Or, perhaps, much of anything in the way of inventory optimisation.

According to research, the vast majority of businesses have only “somewhat” focused on inventory optimisation over the last 2 years.

It’s understandable to not be focused on every part of your business, 100% of the time. For the last few years, supply chain teams have moved from one crisis to the next.

But this is your canary down the coal mine chirping about your inventory.

Look at it now, before the air gets too stale.

The combination of the warehouse space shortages, price increases and staffing issues will force you and many others into action.

So, you need to get inventory optimisation back on your agenda.

The good news is that your problems can be solved.

The first step on the ladder

Naturally, there are times when it makes sense to stock up. Just like, there are times when it makes sense to do the opposite and go lean.

You already know that. But your also aware that you can’t simply write off your excess stock from clogging up your warehouse space.

So, what do you do? Do you bury you head in the sand and hope for the best? Of course not, you need to come out fighting.

The most successful businesses are those that can anticipate what’s on the horizon and have the means to act. So, how can you start performing like one of these?

Every year, we help 000s of supply chain teams to optimise their supply chain processes. The businesses that yield the fastest and most impactful results understand the 3 key factors that underpin supply chain success:

- Create greater visibility

- Focus on what matters

- Improve overall control

But most importantly, they pursue these goals with anger.

And for details on how you can do the same, keep reading…

1. Creating greater visibility

Accurate forecasts are the driving the force behind good inventory decision making.

If you don’t trust the forecast, you might cover the ‘gap’ with additional stock. Only now, you no longer have the warehouse space to afford this luxury.

Therefore, the first step is to take steps to improve forecast accuracy.

So, how can use the abundance of data in your business to make better, more robust decisions?

Assumption’s the mother of all evil

Sure, guesswork is great. Even the best of us will rely on our gutfeel from time to time.

But be warned, if you make assumptions based on the general ‘vibe’ of the market, you’re going to make some costly mistakes.

You’ll stock out. You’ll face obsolescence. You’ll see excess waste.

And even on your ‘stable’ products, you’ll end up with sky-high inventory levels.

Too many companies have previously forecasted demand at too broad a level, often due to limited time… and we’ll come to that, but it simply isn’t enough in the current environment.

And so, my point is, to make good supply chain decisions, you need visibility, yes. But just as importantly, you need visibility at the right level of granularity.

So, how can you anticipate demand with confidence?

Chances are there are glaring gaps in your data. It’s your job to fill those gaps.

To clear the windscreen and see the road ahead, there are few main areas you need to focus on for accurate demand planning & forecasting:

How much demand history is available? And is your data reliable?

Many forecasting models rely on historic data to build an accurate picture of the future. And, of course, the more data you have available, the sharper this picture will be.

If only it was this simple…

What if the product in question is new? In this case, you may not have historic sales data to your disposal.

Equally, what do you do with the COVID years?

Some industries saw huge growth from COVID, some saw the opposite and others stayed true. Sure, you have the data. But is it wise to carry on though nothing had happened? Or should treat this period as a prolonged anomaly and exclude from your plans completely?

Put simply, data is one of the most valuable assets your business has. But to unlock its full potential, your data requires proper and regular maintenance.

Top Tip: To keep your data in tip-top shape, click here to check out our handy guide to Master Data.

What horizon do you need to plan for?

Planning horizons are important. That much is obvious.

In some industries, businesses need to anticipate their inventory requires months or even years into the future to secure supply. Bikes are a perfect example.

With wide-spread supply shortages and back orders to contend with, many businesses in this space now anticipate demand several years into the future.

For some businesses, its essential that the forecast for the next few weeks or even days is spot-on. Take the food industry, for example. Given the short product shelf lives, attaining visibility over the short-term day-to-day demand volatility is far more important than anticipating how many cabbages may (or may not) sell 5 years from now.

The ‘right’ planning horizon depends totally on your business. If your planning horizons are too short, you may lose sight of the bigger picture. Equally, if your planning horizons are too broad, you may be to slow to react to sudden shifts in demand.

How do you enrich your forecast with market intelligence?

Your customers’ requirements may look very different tomorrow compared to a year ago. Things change and the world moves on. The problem is that historic data can only tell you so much.

Therefore, you may need to enrich your forecasts with solid market intelligence.

This invaluable insight can come from a range of sources. For example, your sales team probably have an intimate relationship with your customers. And therefore, they may hold gems of information regarding your customers plans and ambitions for the future.

Perhaps your insights come straight from the horse’s mouth. If your customers share purchase forecasts, this is fantastic data you can use to align your own supply chain plans.

Whether this market intelligence comes from your sales team, directly from the customer or from another source, the challenge here is ensuring that this data is reliable.

And for this, we need effective collaboration…

How can you validate your forecasts through collaboration?

So, by this point, you two perspectives of future demand. On one hand you have the statistical forecasts based on the robust historic demand data. And on the other, you have a forecast based on market intelligence.

To build the most accurate forecast, you somehow need to combine these two perspectives to achieve a single-source-of truth.

Thankfully, this is where S&OP can help us out.

S&OP is the hymn sheet you should all be singing from. However, on tune each department sounds, harmony’s the goal. Or at the very least, everyone must be singing the same melody.

Sure, S&OP underpins many business processes. However, when it comes to validating forecasts, S&OP is a handy tool indeed. By providing a platform where multiple teams can collaborate, and constructively challenge one another, you can achieve a consensus on what the final forecast should look like.

So, who’s involved in your process? Who’s not and should be?

2. How can you stay focused on what matters?

We have explored the importance of robust forecasting. But even the best forecast is pointless if you do not have the time to execute it.The problem for many businesses is that they are distracted by too many things add little value.

Look at your warehouse. Is it full to the brim with your most important products? Or is it clogged with products that offer poor margins and slow sales?

When you have thousands of products to manage, in combination with all the demand and supply challenges you’re facing, it’s very easy to get lost in the weeds.

It’s even easier however to get distracted by firefighting, rather than focus on the tasks that really add value.

The result of course is that inventory levels creep up on you and soon you find yourself drowning in stock.

Therefore, you need to bring focus to your world.

A typical ABC pareto

The first question you should ask yourself is: “Are we selling the right products?”

Secondly, do you understand which products are important & why?

Every product in your warehouse should earn its place. But even then, different products contribute different levels of value. Therefore, where should you prioritise your time and financial investment in stock?

These are valid questions. Thankfully, a simple ABC Analysis can provide the answers.

If you base your inventory decisions based on a finger in the air, this is not enough for the current climate. But a robust ABC analysis can quickly provide invaluable insight into what products deserve your time and money.

The end goal of course is to identify which are your A, B & C products. And with this, you can determine more appropriate service levels, optimise ordering processes, and maybe even cull the items that really don’t help you out.

Unfortunately, you can’t just complete an ABC analysis and forget about it.

Your product assortment is dynamic. There are many factors that influence it.

For instance, do your priorities shift depending on the time of year and the season? You don’t want to be overstocking expensive products in periods where you just don’t need them. It’s wasteful for many areas of the business.

Likewise, can you afford to prioritise your products based on just one parameter? Sales is obvious, but should you also reviewing margins to ensure your products drive value?

Finally, should you now be focusing your time on key customers? Do you know who your key customers are? And the risk they pose to your SKUs? Afterall, is it a risk to overstock on a product because a single customer buys 80% of it?

Top tip: To deploy this handy tool in your business, check out our complete guide to ABC Analysis.

You also need to rationalise your workload

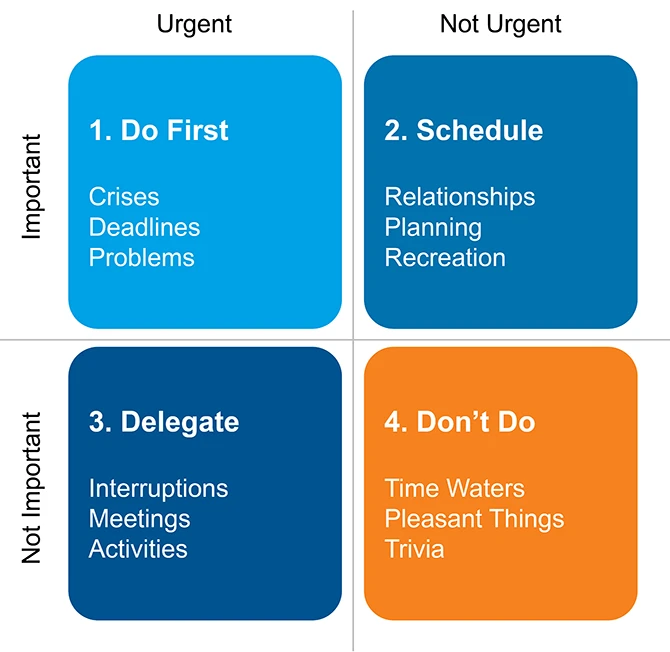

Lots of planning teams exist in a constant state of firefighting. The covey matrix helps you understand what’s important versus what isn’t.

Given that C items probably add limited value to your business, it makes sense that any issues with these products appears lower down your To-Do List.

Yet, even for “A” products, you need to prioritise what is going to have the biggest impact (Urgent & Important).

This is all about workload management and putting focus in the right places.

3. How can you improve overall control?

So far, we have focused on challenges that you actively influence.

But there are a lot of supply chain factors that are out of your control.

Even if you had a magical ball, could you have anticipated the recent upheaval we have seen from…

- Disruption at the ports

- Container shortages

- Unforeseen supplier capacity issues

Let’s face it, uncertainty is one of the main reasons why so many businesses now carry such high levels of inventory.

Afterall, these events have huge impact on global supply chain:

- Longer & less reliable lead times

- Higher distribution costs

- Lack of trust throughout the supply chain leading to a global bullwhip effect

But that is no excuse. There are steps you can take to mitigate risk without having to over invest in excess stock.

Let’s explore a few examples…

Work with your suppliers

In many ways, your success depends on your suppliers.

Yet, until they receive your signed purchase order, your suppliers are often completely in the dark. So, perhaps it time to enlighten them.

This may mean sharing your purchase forecasts. Equally, this can also mean tracking & challenging poor supplier performance.

Just by opening communication channels with your supply chain partners, you can build stronger relationships. And building trust throughout the supply chain can go a long way in helping you to stay one step ahead of disruption.

Update your supplier data

We have already talked about the importance of good data. But the integrity of you supplier parameters is equally as important.

If you haven’t looked at your Master data since 2019, you could find yourself in hot water now. Afterall, if lead times are now twice as long or the supplier MOQ has changed, how can you be confident that you are ordering accurately?

Up to date supplier data will allow you to order efficiently. And this in turn can help you to achieve your availability goals; all while minimising inventory levels and supply chain costs in the process. But someone has to ‘own’ this Master data and make it their mission to maintain it.

Build a more responsive process

There are lots of reason why businesses find themselves in positions of inventory mismanagement.

But let’s address the elephant in the room…

Many business leaders simply lack the tools to manage inventory both strategically and dynamically.

Did you know 75% of businesses depend on ERP or spreadsheet-based systems to keep things in check?

Yet, there’s so many moving pieces to worry about, even the most advanced spreadsheet in the world would fall short. Not to mention that spreadsheets need constant scrutiny.

Even the best ERPs lack the flexibility to respond to the rate of change most businesses face.

Therefore, it’s no surprise so many are sat on a mountain of inventory with nowhere to store it.

But that shouldn’t be the case for you.

Strike now or risk being left behind…

The tides are turning. Many are starting to wake up the realities of their situation. Whilst inventory optimisation may have been overlooked in recent times, by you and your competitors, businesses are now ready to act.

In fact, according to reports 64% of businesses are planning to make investments in inventory management systems in the coming 2-3 years.

So statistically, if that’s not you, it’s your competitor.

So, do you sit and wait for them to act, and hope for the best? Or do you grab the bull by the horns and see what’s available on the market to help your quest?

Warehouse space FAQs

How can businesses ensure effective collaboration and communication between inventory management teams and warehouse operations to maximize space utilization?

If warehouse space is at a premium in your business, Sales and Operations Planning (S&OP) can play a crucial role in facilitating effective collaboration and communication between inventory management teams and warehouse operations. By aligning decisions around order levels, delivery schedules and operational constraints, an effective S&OP process should facilitate a more peaceful operation while ensuring the most efficient use of the warehouse space available.

Why is inventory management important for businesses facing warehouse space issues?

For any business struggling with warehouse space issues, effective inventory management is crucial. Afterall, what stock you hold, when you order and how much are the driving force behind how well you available space is utilised. Effective inventory management ensures that businesses have the right amount of stock on hand, avoiding both excess inventory and stockouts.

How can businesses prioritize their inventory to make the most efficient use of available space?

Some of your items are more important than others. And if you fill you warehouse up with those items that add little value to your customers or your bottom line, this is likely to be a huge waste of warehouse space. Therefore, its important that you have a clear understanding on how to prioritise your assortment. Though undertaking a detailed ABC analysis and applying well-considered service level targets, you can adjust inventory levels accordingly and maximise the use of available warehouse space.

What role does technology play in improving inventory management and addressing warehouse space constraints?

Your S&OP process, in combination with the right technology, can help you to address your warehouse space shortage. For examples, by deploying advanced AI-powered demand planning tools, you can attain better visibility which in turn can minimis risk of excess.

In addition, by enabling real-time scenario planning, digital tools allow businesses to simulating different inventory strategies and their impact on warehouse space utilization. Through adjusting reorder points, changing production schedules, or modifying safety stock levels you can identify and implement the optimal inventory management approach.