Overview

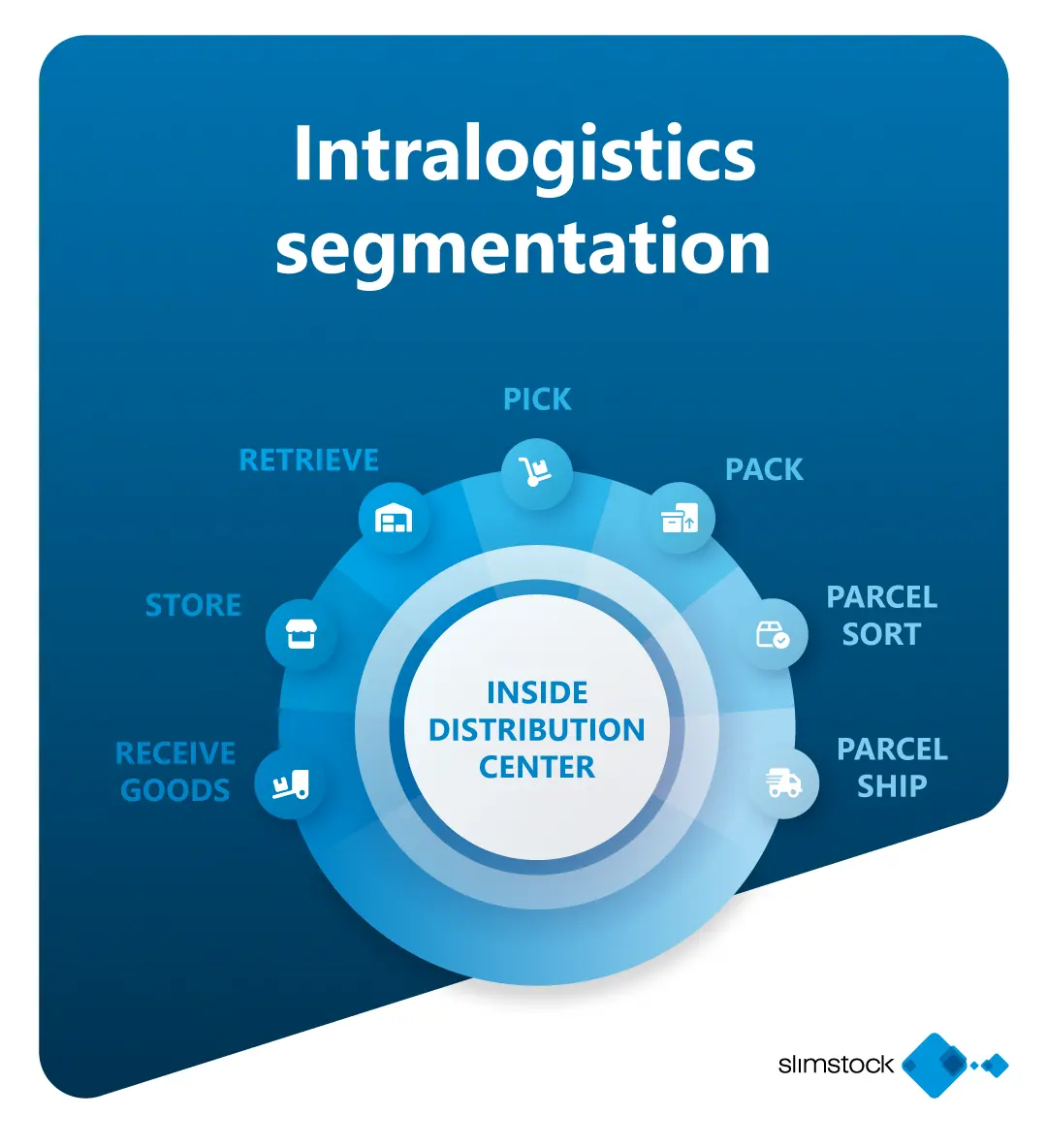

Intralogistics is the operational core of a warehouse, encompassing all internal movements of goods from reception to shipping, including storage, picking and packing. It is essential for efficiency, cost reduction and customer satisfaction, with significant time spent on transport (60%) and picking/packing (30%). Optimizing these processes involves leveraging advanced technologies like Automated Guided Vehicles (AGVs) and various automated storage and sorting systems to improve speed and accuracy.

What is intralogistics?

Intralogistics is the operational core of any distribution centre or warehouse, encompassing critical warehouse processes that ensure the efficient movement of goods. From reception and storage to picking, packing, and shipping, each of these activities directly contributes to operational speed, cost reduction, and customer satisfaction.

A revealing statistic is that transport tasks account for approximately 60% of total operational time, while picking and packing represent 30%, leaving only 10% for waiting times. This imbalance highlights the need to integrate advanced technologies, such as Automated Guided Vehicles (AGVs) with intelligent navigation and automated solutions for picking and sorting, to achieve higher levels of efficiency and productivity.

Intralogistics activities

Intralogistics encompasses various activities that ensure an efficient flow of goods within the distribution centre. This article reviews each of them.

Parcel reception

- Involves unloading goods from loading bays and reception areas.

- Ensures that products arrive at the warehouse in proper condition.

Parcel storage

- Consists of moving products from the reception area to the storage system.

- Goods are organised for easy access and future management.

Parcel retrieval

- Involves moving products from the storage system to the picking area.

- Prepares goods for order fulfilment.

Picking

- The correct products are selected according to specific orders.

- A key stage in order preparation.

Packing

- Selected items are placed in a box and secured for shipping.

- Orders are verified and properly packed.

Parcel sorting

- Parcels are classified according to their shipping destination.

- Facilitates efficient distribution.

Parcel shipping

- Sorted parcels are loaded onto transport vehicles for final delivery.

- The final stage of the process within the distribution centre.

Goods transport

Goods transport is a crucial activity within intralogistics, accounting for approximately 60% of the total operational time in a warehouse or distribution centre. Transport connects all processes within intralogistics operations, and proper planning of work routes helps optimise time and costs while reducing errors.

To improve operational efficiency in this area, technologies such as Automated Guided Vehicles (AGVs) have become essential solutions. These systems have evolved from navigation based on magnetic strips (wire-guided), common in the 1960s, to laser-guided technology in the 1990s. Today, the incorporation of artificial intelligence enables vehicles to use SLAM (Simultaneous Localisation And Mapping) navigation, which allows a robot or drone to generate a real-time map of its environment as it moves through it, even when the area is unfamiliar.

Automated Guided Vehicle (AGV) technology

AGVs are characterised by their ability to move autonomously within facilities, following predefined or digitally mapped trajectories. Depending on their navigation system, they can be classified into:

Line follower

These vehicles follow physical routes marked on the floor, such as painted lines, magnets, or QR codes. While they are simpler and more cost-effective, their flexibility is limited as any route changes require physical modifications to the environment.

Map follower

Map Follower AGVs use digital maps, either predefined or generated via sensors. Traditional navigation technologies rely on static maps created from CAD or environmental contours, whereas SLAM-based systems dynamically create and update maps. The combination of Lidar, cameras, and other sensors ensures precision and adaptability to various scenarios.

Steps to design a goods transport system

To design an efficient transport system, detailed planning is essential:

- Define the circuits or movement routes for goods within the warehouse.

- Analyse the cycle time or takt time for each route.

- Establish the average and maximum permitted speeds.

- Calculate the total cycle time, including stops and recharges.

- Determine the optimal number of AGVs required to meet operational demands.

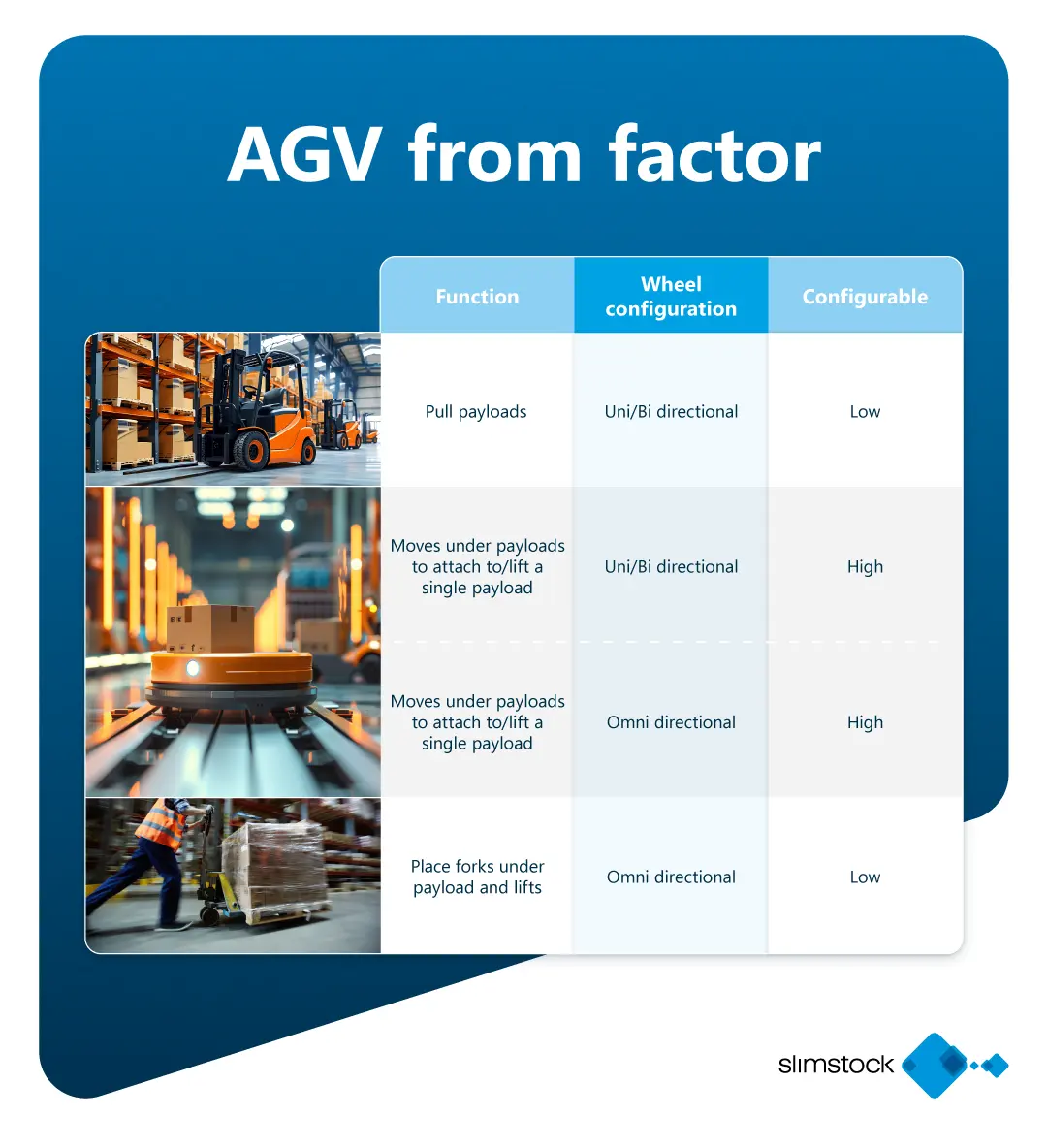

AGV devices for goods transport

AGVs come in different configurations depending on their specific functions:

Tugger or tow tractor

Tuggers or tow tractors are designed to tow carts or load trains. They are ideal for continuous replenishment tasks, such as milk-run routes, improving efficiency along predefined paths.

Forklift or counterbalance truck

Forklifts, commonly known as counterbalance trucks in the UK, are AGVs that handle pallets and can be adapted to transport other types of loads, such as drums or paper rolls. They are commonly used to move goods from production to storage, between warehouse zones, or from the warehouse interior to dispatch areas.

Mouse

Mouse AGVs are known for their versatility and ability to position themselves under loads and lift them. Their popularity has increased due to SLAM navigation and their 360-degree turning capability, making them a flexible solution for high-density, space-constrained environments. They play a key role in all “goods-to-person” picking systems.

Goods storage

Storage is a fundamental stage within intralogistics, ensuring efficient organisation of products to facilitate retrieval and order preparation. Choosing the right storage system depends on product volume, turnover rates, and available space.

Some of the automated storage systems include:

Shuttle

The shuttle system is a highly efficient solution for automated storage. It consists of automated vehicles (storage units) that move within racking systems, transporting goods between storage levels and picking stations. Shuttles stand out for their speed and flexibility, allowing for dynamic inventory management and significantly improving productivity in high-turnover environments.

Lift warehouse

The Lift Warehouse system is an automated solution designed to maximise the use of vertical space in a warehouse. This technology employs lifts that transport trays of products between different storage levels to picking or replenishment stations. Its vertical structure makes full use of warehouse height, making it an ideal choice for facilities with limited horizontal space.

This system is notable for its capacity to store a large number of products in a compact area, increasing storage density and optimising available resources.

Carousel warehouse

The Carousel Warehouse is another automated storage system that utilises continuous movement to efficiently organise and retrieve goods. This system can be either horizontal or vertical, depending on warehouse requirements, and features trays or baskets that move in a closed-loop system. This mechanism brings required products directly to picking stations, eliminating the need for operators to move around the facility.

The Carousel Warehouse is particularly useful for storing small to medium-sized, high-turnover products, making it an ideal solution for industries such as e-commerce and retail distribution.

Pick & pack operations

Pick & pack operations combine product retrieval with immediate packaging. This integration streamlines workflow, minimising the time between picking and dispatch, which is essential for improving efficiency in distribution centres handling high order volumes.

Multi-Order picking

Multi-order picking is a process designed to prepare multiple orders simultaneously, which is particularly useful in B2C environments with high volumes and small order quantities. This approach reduces the number of trips required within the warehouse, though its efficiency can decrease as SKU numbers or operational complexity increase. To prevent excessive movement, a multi-SKU zone can be implemented, or storage areas can be reconfigured, shifting from pallet handling to box-based solutions.

Batch picking

Batch picking involves grouping multiple orders with similar items and collecting them in a single run before sorting them by order. This method enhances process efficiency and is ideal for operations with high demand for common products, reducing overall picking time and maximising workforce or automated resource utilisation.

Fine picking

Fine picking focuses on the precise selection of individual units or small items. This operation requires a high level of accuracy and is critical in e-commerce environments or where order customisation is essential.

Batch picking and manual fine picking

Combining batch picking with manual fine picking is a hybrid strategy that maximises efficiency in complex operations. Large batches are collected initially, followed by a detailed manual selection process to ensure accuracy and customisation for each order.

Batch picking with goods-to-person solutions

The use of goods-to-person solutions alongside batch picking automates the process, delivering products directly to the operator instead of requiring them to move around the warehouse. This approach improves ergonomics, reduces cycle times, and increases order preparation speed.

Parcel sorting

Parcel sorting operations are essential in modern intralogistics, particularly with the rise of e-commerce, which has increased the complexity of transport solutions, such as last-mile delivery.

Understanding and optimising this process enables distribution centres to quickly adapt to changes and enhance overall efficiency. Various systems are used to achieve this.

Push sorter

The push sorter is a system designed to handle a specific volume of parcels per hour. While it offers high sorting accuracy, its lack of flexibility and scalability limits its adaptability to new demands. Additionally, its operation is directly dependent on the type of parcel being processed.

Pop-up sorter

The pop-up sorter is a modular solution that enables high-performance sorting. Although scalable due to its modular design, it lacks flexibility in adapting to different types of parcels. Its efficiency makes it a solid choice for operations with constant and predictable demands.

Cross belt sorter

The cross belt sorter stands out for its ability to efficiently handle high volumes of parcels. This system is independent of parcel type, giving it a significant advantage over other technologies. However, it is neither flexible nor scalable, which limits its adaptability to future changes.

AMR sorting

The Autonomous Mobile Robot (AMR) sorting system uses robots guided by QR codes on the floor. Its main strength lies in its flexibility and scalability, allowing sorting capacity to be easily adjusted according to business needs. Additionally, it is independent of parcel type, maximising versatility and efficiency in dynamic and ever-evolving operations.

Split tray sorter with dynamic box allocation

The split tray sorter is an automated solution that distributes products into dynamically assigned boxes for each customer. This technology enables the handling of a wide variety of products with precision, improving sorting capacity and order processing speed.

Fly sorter

The fly sorter is a highly efficient system that organises products based on their final destination. Its ability to handle up to 3,500 units per hour makes it an ideal solution for distribution centres with high processing rates and for managing returns.

Parcel shipping

The parcel shipping phase represents the final step within the intralogistics processes in a distribution centre. At this stage, the parcels, already sorted, are prepared for transport to their final destinations. This phase marks the transition from internal intralogistics to the external transportation system, ensuring that products arrive on time and in the expected condition. This phase involves:

Loading of parcels onto vehicles:

- The parcels, sorted by destination, are strategically organised to optimise space in the transport vehicles, whether they are lorries, vans, or other means of transport.

- It is crucial to ensure that the distribution of the load complies with safety regulations and allows for efficient access for future deliveries.

Shipment verification:

- Before loading, a final check is carried out to confirm that each parcel is correctly labelled and associated with the right transport.

- This step minimises delivery errors and ensures that parcels reach their recipients without issues.

Documentation management:

- The necessary documents for transport are generated and processed, such as cargo manifests, delivery notes, and tracking labels.

- These documents are essential for the traceability of shipments.

Conclusions

Designing an efficient intralogistics operation requires considering the following phases and needs in a comprehensive manner:

- Consider the importance of goods transport operations: Optimising how products are moved within the warehouse is key to reducing downtime and improving efficiency.

- Define storage needs: Adapting storage strategies to product volume, turnover, and available space maximises resource utilisation.

- Calculate picking and packing requirements: Integrating advanced solutions for these stages reduces errors, accelerates order preparation, and improves the customer experience.

- Optimise parcel shipping processes: The shipping stage is the last point to ensure products reach the end customer quickly and efficiently. Implementing technologies such as transport management systems (TMS) and automated sorting enhances speed, accuracy, and shipment traceability, reducing costs and boosting customer satisfaction.

- Don’t forget returns management: Returns represent an increasingly important aspect of e-commerce. Planning specific processes for handling returns ensures a sustainable and efficient operation.

In an ever-evolving logistics environment, investing in automation, flexibility, and scalable solutions not only improves current efficiency but also positions businesses to successfully face future challenges.

FAQs about intralogistics

What is intralogistics?

Intralogistics refers to the management, organisation, and optimisation of internal flows of materials, goods, and data within a warehouse or distribution centre. It includes processes such as storage, handling, transportation, and order preparation. Its main objective is to ensure that products and information move efficiently and accurately within the premises, thereby improving productivity and reducing operational costs.

What are the benefits of efficient intralogistics?

Efficient intralogistics optimises the use of resources, reduces errors in inventory management, and speeds up order fulfilment. It also minimises operational costs by enhancing productivity and maximising space utilisation. Additionally, it increases customer satisfaction by ensuring fast and accurate deliveries, which is crucial in sectors such as e-commerce and distribution. In short, it contributes to the overall success of the supply chain.

What challenges do intralogistics operations face?

Among the main challenges are the growing demand for speed in order preparation, the need to manage a wider variety of products and fluctuating volumes, and the integration of advanced technologies. Moreover, companies face space limitations, high labour costs, and pressure to operate sustainably, which requires a balance between operational efficiency and reducing environmental impact.

What is the role of technology in intralogistics operations?

Technology plays a key role in modern intralogistics by automating processes, improving accuracy, and optimising efficiency. Systems such as robots, automated guided vehicles (AGVs), warehouse management software (WMS), and IoT solutions enable real-time control of internal flows. These tools not only reduce errors and costs, but also facilitate adaptation to changing demands and data-driven decision-making.