Overview

This article highlights 10 critical supplier KPIs, from measurable metrics like On-Time In-Full (OTIF), lead-time variance, and defect rates, to softer factors such as sustainability, innovation, and collaboration quality. Suppliers can make or break your success, so cultivating a high level of trust with them is essential

In an ideal world, respect is mutual, arned over years of partnership. Ultimately, a supplier’s promises and their ability to keep them directly affect your ability to keep your own promises. And if you fail to deliver, it’s your customers who are left renegotiating, sometimes by taking their business elsewhere.

Having suppliers who meet demand is one thing, but you also need suppliers who support your growth, sustainability and innovation objectives. Suppliers who are valuable now, and worth keeping in the long term. Suppliers who can grow with you. Suppliers who help you achieve your goals, rather than hinder them.

And yet, all too often, they don’t. When a delivery fails to arrive, underperformance is an obvious problem. Other times, pinpointing the issue is trickier. Worse still, sometimes you only realise there’s a problem when it’s too late. Hardly the recipe for a stable supply chain, right?

The need for supplier KPIs

To assess whether your suppliers are meeting expectations, you need KPIs. These indicators provide insight into the quality of your supplier relationships and measure the value each supplier delivers.

KPIs should also help you spot potential issues before they escalate or, at worst, before “the horse has bolted.”

Once KPIs are in place, effective collaboration becomes much easier, and strategic decision-making can follow a clear, structured process.

Which KPIs should you track?

There’s almost an endless amount of data available on your suppliers. Some metrics, naturally, are more important than others and should carry more weight.

If you can quantify supplier performance in black and white, you should. Data-driven metrics are easily visualised, simple to report, and enable informed decisions. However, not every KPI can be quantified so neatly. Supplier relationships are far more nuanced than any chart can show. Monitoring performance should go beyond numbers to highlight issues that raw data alone cannot capture. Pay attention to less tangible aspects of performance, and your supply chain and your business will grow stronger together.

10 supplier performance KPIs you should implement now

Let’s start with the tangible metrics, they’re the easiest to track.

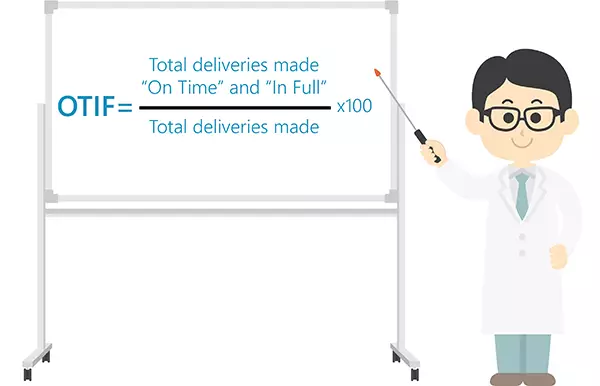

1. Supplier OTIF (On-Time In-Full)

OTIF measures a supplier’s reliability. Are they on time? Is the order complete?

It’s usually the most obvious metric to flag when deliveries fail. So much so that suppliers will typically inform you in advance if a delay is expected. But OTIF doesn’t tell the full story.

2. Lead-time variance

Lead time is critical for inventory planning. If a supplier promises a 12-week delivery but takes 24 weeks, it will cause issues across the business. Conversely, early deliveries can create urgent storage challenges, which aren’t cheap.

Lead times determine order timing, safety stock requirements and reorder frequency. There are many reasons lead times may vary, and it isn’t always the supplier’s fault. But incorrect lead times must be challenged sooner rather than later.

3. Defect rate

Defects, like OTIF or lead-time variance, are obvious blockers. Even perfect OTIF scores are meaningless if half of the shipment is damaged or substandard. Customers won’t accept faulty products, and neither should you.

Whether damage occurs in transit or materials fail to meet specifications, it’s essential to investigate the cause thoroughly.

4. Volume variance

Receiving too few or too many items can be as disruptive as lead-time issues, especially if it affects revenue or causes additional costs. Volumes must be precise, every time. Incorrect order quantities trigger a chain reaction such as misaligned packaging, pallet sizes and increased operational costs.

5. Supplier ROI

What value does this supplier bring? How does the cost of working with them compare to competitors? Is it good value for money, or are you overpaying?

Suppliers promise value, it’s up to you to verify whether they deliver. Without measurable ROI, you’re unlikely to see meaningful returns.

The less tangible supplier KPIs

Focusing only on obvious, data-driven metrics is short-sighted. Here are some of the more nuanced aspects of supplier performance to track:

6. Sustainability

Sustainability should be more than a marketing buzzword. Consumers care about sustainability, it’s no longer optional. Can your company truly claim to be sustainable if your supply chain partners disregard environmental impact?

Some industries, such as food and paper, have clear sustainability standards. Using these as a baseline is a good start, but supplier-specific KPIs may be needed to fully monitor environmental responsibility.

7. Innovation

If you invest heavily in research and development, your suppliers must match your innovation ambitions.

How do they invest in R&D? Are they evolving their offerings? Can they meet market demands and diversify products? Are they capable of supporting new global markets quickly?

These questions ensure suppliers are genuinely innovative, not just claiming to be.

8. Flexibility

Is your supplier adaptable, or rigid and inflexible? Unexpected challenges arise frequently, that’s why you need a supplier who can respond effectively, not one who leaves you stranded.

9. Risk mitigation

Proactive risk management is essential. Agility is valuable, but it cannot replace suppliers who actively mitigate operational risks.

You may need first-hand insight into their risk management processes. If Covid taught us anything, it’s to expect the unexpected. Ask suppliers what measures they have in place to ensure order fulfilment even under extreme circumstances. Some will excel; others may rely on flexibility alone.

10. Ease of collaboration

A frequently overlooked but critical KPI.

Sure, you want suppliers who deliver on time, in full, and to specification. But you also need partners who value collaboration, respect your business, and support seamless working relationships.

Some suppliers actively facilitate smooth cooperation. Others merely process orders, abandoning you when problems arise. Do they share supply chain insights? Challenge your processes constructively? Help you improve?

Closing thoughts

Suppliers are more than just order fulfiller, they are strategic partners. The right KPIs give you the insight to nurture relationships that drive growth, innovation, and resilience.

By tracking both tangible metrics like OTIF, defect rates and volume variance, as well as softer indicators such as sustainability, flexibility and collaboration, you can ensure your suppliers not only meet today’s demands but also support your long-term goals.

Investing the time to define, monitor and act on these KPIs isn’t just good practice, it’s essential for building a supply chain that works for you, your customers and your business.

Remember: strong suppliers make strong businesses. Measure wisely, collaborate closely and watch your supply chain thrive.