Table of contents

Table of contents- What is a SKU and how to manage them efficiently

- What is an SKU?

- How many SKUs should a company have?

- What is the difference between SKUs and other identification codes?

- How to manage SKUs efficiently

- Conclusion: prioritise your SKUs

- FAQs about SKUs

Overview

A Stock Keeping Unit (SKU) is a unique, internal alphanumeric identifier for each specific product variant in inventory, for example, combining model, size and color. Efficient SKU management is vital for optimising inventory, reducing costs, and improving availability. The ideal number of SKUs depends on business strategy (variety versus efficiency) and efficient management requires aligning the assortment with objectives and prioritising SKUs with methods like ABC analysis.

What elements influence the complexity of a company’s operations? Many and varied. If we focus on the supply chain, some of the main challenges are the diversity and dispersion of suppliers, the challenges linked to logistics and distribution, the nature of the product – transporting fresh products is very different to transporting screws -, the variability and unpredictability of demand…

The breadth of the assortment is another factor that determines the complexity of operations, since the more SKUs, the greater the operational challenges. In this article we will focus precisely on what SKUs are and how they can be managed efficiently.

What is an SKU?

An SKU (Stock Keeping Unit) is a unique alphanumeric identifier assigned to each specific variant of a product within an inventory management system. Its main function is to facilitate the tracking, control and replenishment of stock in warehouses and points of sale.

Technical characteristics:

- Customised structure, usually combining attributes such as category, model, size, colour or location.

- Function in ERP/WMS systems, allowing automation in inventory, replenishment and sales analysis.

An example SKU of an ‘Air Jordan’ model ‘38’ trainer in size 42, colour black could be AirJordan-38-42-NG.

According to this definition, the term ‘SKU’ is almost equivalent to the term ‘reference’. At Slimstock, however, we understand the SKU as the combination of this reference code with its location centre.

In order to maintain the focus, we won’t go into the topic of localisation in this article, and will address this question in a future article.

How many SKUs should a company have?

Obviously, there is no single right answer to this question. At Slimstock, we have one customer in the energy sector with one SKU, and many distributors with tens of thousands of SKUs.

Therefore, the number of SKUs will depend entirely on the business sector in which your company operates. However, two companies in the same business may have a very different number of SKUs. Why is this? Mainly because of different business strategies.

1. Assortment strategy and catalogue depth

Companies wih many SKUs opt for a strategy of wide variety and customisation, offering multiple options of the same product (different brands, qualities, colours, sizes, materials, etc.).

Companies with fewer SKUs focus on a smaller but optimised offer, prioritising high turnover products and reducing operational complexity.

2. Inventory management and logistics costs

Companies with many SKUs face Increased complexity in storage, replenishment and management costs (warehouse space, obsolescence, dead stock).

Companies with fewer SKUs achieve a more efficient operation, lower warehousing costs, less risk of overstocking and better purchasing optimisation.

3. Differentiation and positioning strategy

Companies with many SKUs can target a more specialised market and offer premium or niche options.

Companies with fewer SKUs focus on standardisation and efficiency, possibly with a low-price, high-turnover strategy.

In essence, the difference in the number of SKUs reflects a strategic decision on product offering, operational efficiency and market positioning.

A company with many SKUs focuses on variety and customisation, while one with fewer SKUs prioritises efficiency, simplicity and cost optimisation.

Want to take your SKU management to the next level? Check out how Slimstock’s demand planning software can help you forecast demand accurately, optimise inventory and make smarter assortment

What is the difference between SKUs and other identification codes?

SKUs (Stock Keeping Units) are just one of several identification systems used in product and inventory management.

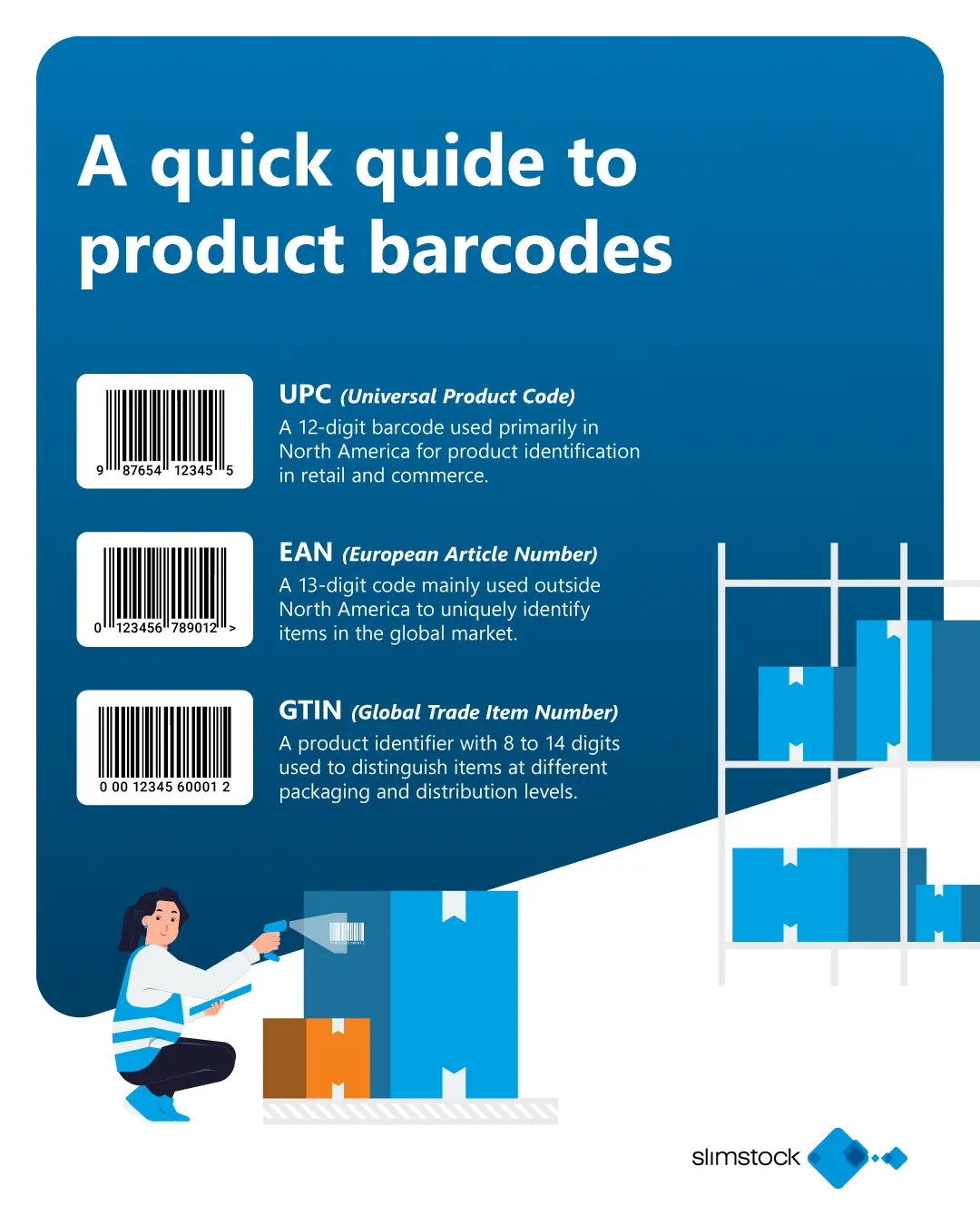

| Code | Description | Structure | Standardisation Level |

|---|---|---|---|

| UPC | Universal Product Code | 12-digit numeric | Regulated by GS1, unique for each product worldwide |

| EAN | European Article Number | Either 13 digits (EAN-13) or 8 digits (EAN-8, used for smaller products) | Regulated by GS1, unique for each product |

| GTIN | Global Trade Item Number | It can have 8, 12, 13 or 14 digits | Regulated by GS1, acts as an umbrella standard that includes UPC and EAN formats |

What do the 13 digits of the EAN mean?

- First 3 digits: Country code or GS1 organisation prefix (e.g. 840-849 for Spain, 750 for Mexico).

- Next digits (4-9): Company code assigned by GS1 to a brand or manufacturer.

- Next digits (10-12): Product code determined by the company to identify a specific item.

- Last digit (13): Check digit, mathematically calculated to validate that the code is correct.

What is the main difference between SKU and other identification codes?

The main difference between SKU and other identification codes is that SKU is internal and customised, while codes such as UPC, EAN and GTIN are standard worldwide.

While a product can have several codes simultaneously (e.g., an internal SKU and a global UPC), the use of each code depends on the operational and business context.

How to manage SKUs efficiently

As seen above, the number of SKUs in your company will depend on your business strategy. This will determine whether your assortment is broad or streamlined.

However, there are some general rules that apply to any company when it comes to assortment management and optimising SKU selection. We highlight 10 steps.

Step 1: Determine the company’s ambitions and objectives

The product assortment should be aligned with the company’s strategic objectives, be it cost reduction or expansion into new markets.

Step 2: Identify key customers

It is essential to define whether the assortment will cater to frequent buyers or occasional customers, depending on the company’s strategy and the sector in which it operates.

Step 3: Explore the market

Analysing competitors’ offerings and identifying opportunities in the assortment allows for differentiation and improved competitiveness.

Step 4: Set assortment objectives

Defining clear targets such as revenue, margin levels, customer satisfaction or product availability helps to measure the success of the assortment.

Step 5: Organise the assortment

Classifying products into logical categories makes it easier to manage them and analyse their performance.

Step 6: Assess current performance and identify gaps

Before making changes to the assortment, it is key to analyse which products add value and which are loss-making.

Step 7: Anticipate the potential for new items

Anticipating the performance of new products through sales data of similar items or market information minimises uncertainty.

Step 8: Update the assortment

Deciding which products to keep or eliminate should be based on rational analysis, not assumptions or external pressures.

Step 9: Execute the assortment plan

Executing the plan includes placing orders, distributing inventory, and fine-tuning replenishment processes to align with demand.

Step 10: Monitor results

Periodically reviewing assortment performance allows you to adjust to changes in the market and customer expectations.

Kave Home: 7% SKU reduction with -40% stock level

In growing companies, it is important to keep the assortment under control. Since the implementation of Slim4, Kave Home has reduced its SKUs by 7% and cut its stock by 40%. This allowed it to free up 14,000 square metres of warehouse space. All this, while managing to increase turnover by 30%.

Conclusion: prioritise your SKUs

The number of SKUs (SKUs) that make up your assortment will largely depend on your business strategy. However, what is universally true is that you cannot give equal importance to all of them.

If you pay the same attention to a product that accounts for a very high percentage of your company’s turnover and from which you make a large profit margin, as you do to a SKU that is only sold on a very occasional basis, you will be making a mistake.

For this reason it’s important that you implement an effective ABC analysis in your company and support you in the management by exception, especially for those less important SKUs that you want to keep in your assortment.

FAQs about SKUs

Why is it important to manage SKUs efficiently?

Efficient SKU management allows you to optimise inventory levels, reduce operating costs and improve product availability. It also prevents overstocking and dead stock accumulation, which contributes to a leaner and more profitable supply chain.

How can I avoid having too many SKUs in my company?

To avoid having too many SKUs that complicate operational management, it is key to perform a regular assortment analysis, apply the ABC methodology to prioritise products and eliminate those with low turnover or reduced margins. A data-driven approach is also recommended to introduce new SKUs strategically.

What common mistakes are made when managing SKUs?

Some common mistakes include the unnecessary creation of SKUs for non-significant variations of a product, failure to update the catalogue, keeping obsolete SKUs and lack of integration with technology tools. These mistakes can lead to additional costs and stock problems.

How does technology help SKU management?

ERP systems and other systems such as planning systems facilitate efficient SKU management by automating inventory tracking, improving replenishment accuracy and optimising data-driven decision making. In addition, the use of analytics tools allows you to identify sales patterns and adjust your catalogue strategically.