Table of contents

Table of contents- The cold chain and its logistical implications

- What is the cold chain?

- How does the cold chain work?

- Risks of breaking the cold chain

- Critical moments in the cold chain

- Main sectors where the cold chain is essential

- Conclusion: added complexity, strategic advantage

Overview

The cold chain ensures temperature-sensitive goods, like food and medicine, maintain a controlled environment from production to consumption, requiring specialized logistics, continuous monitoring and strict control to prevent spoilage and health risks from temperature breaches.

It is no secret that supply chain management is a complex undertaking. The reasons for this are many and varied, starting with the fact that many factors lie beyond our control. Who could have foreseen the 2020 pandemic? Or that, in March 2021, a Chinese container ship would block the Suez Canal for a week and disrupt global maritime traffic?

Another unique feature of the supply chain is that it is made up of various interconnected links, mainly raw material producers, manufacturers, distributors, retailers, and end consumers, so what other players, over whom we have limited control, do also affects us directly.

Adding to this challenge, cold chain logistics introduces another layer of complexity, particularly for sectors handling temperature-sensitive goods such as food and pharmaceuticals. These products must be transported under strict temperature conditions to prevent deterioration. In this article, we explore the specific demands of managing the cold chain and how organisations can address them effectively.

What is the cold chain?

The cold chain is a logistics system designed to keep perishable products within a controlled temperature range throughout their entire lifecycle, from origin to end consumer. This process is primarily applied to fresh food, pharmaceuticals, vaccines, and other temperature-sensitive goods.

The key point is not just to chill the products, but to ensure that the correct temperature is maintained at all times. A break in the chain, even if only for a few minutes, can compromise the quality or even the safety of the product. That is why, rather than being a series of processes, the cold chain should be understood as an ongoing commitment to traceability, control, and logistical precision.

How does the cold chain work?

The cold chain operates through a series of stages and controls along the supply flow to ensure that the product never exceeds its safe temperature range. Broadly speaking, the key phases are as follows:

Initial processing and cooling at source

The process begins as soon as the product is manufactured, harvested (in the case of vegetables), or slaughtered (in the case of livestock). At this point, the product must be cooled rapidly to the target temperature. For example, in the food industry, meat or fish is usually placed in cold storage immediately after harvesting. In the case of milk, it is pasteurised and chilled after milking. This early cooling inhibits bacterial growth and prepares the product for preservation. Similarly, in pharmaceutical manufacturing, many heat-sensitive medicines are stored in dedicated freezers or fridges from the outset.

Refrigerated storage

Once processed, products are stored in warehouses or cold rooms. These facilities are built with insulating materials and equipped with refrigeration systems that maintain a constant temperature. It is essential to monitor warehouse conditions continuously using thermometers or automated systems so that any deviations can be identified and corrected immediately.

Temperature-controlled transport

Following storage, the product is transported using specialised vehicles (refrigerated lorries, vans, or insulated containers) capable of maintaining the required temperature throughout the journey. These vehicles feature thermal insulation in the walls, floor, and ceiling, along with independent refrigeration units that can cool the interior regardless of external conditions. They are also fitted with sensors or recorders that monitor the temperature in real time.

Final distribution and sale

The final stage takes place upon arrival at distribution centres, retail outlets, or other points of sale. Unloading teams must act swiftly to return the goods to refrigerated chambers or appropriate display units. In supermarkets, for instance, frozen products are placed directly into commercial freezers, while fresh goods are stored in chilled display cabinets.

This stage may also include last-mile delivery (e.g., fresh food deliveries to homes or vaccines to rural clinics), where portable insulated containers must be used in the absence of small refrigerated vehicles.

Risks of breaking the cold chain

Breaking the cold chain, even momentarily, presents several risks in terms of product quality and even public health. A breach means the product’s temperature moves outside the safe range, which can lead to several consequences, all of them negative:

Loss of product quality and properties

Exposure to incorrect temperatures leads to premature spoilage. Food may become soft, discoloured, or lose flavour and texture. Sensitive medicines may degrade or lose efficacy. For example, ice cream that thaws and refreezes forms ice crystals and loses its consistency. Similarly, a vaccine exposed to heat may become ineffective as its active compounds break down.

Proliferation of microorganisms and health risks

Bacteria and fungi can proliferate rapidly when storage temperatures rise. Food left too long at room temperature may become a source of pathogens that cause food poisoning. Likewise, certain biological medicines may become unsafe.

Economic loss and waste

If a perishable product becomes unfit for use, it must be discarded. This leads to a direct financial loss for the business (equal to the value of the spoiled goods), as well as additional costs for waste disposal and urgent restocking. The environmental and social impact of unnecessary waste must also be considered.

Legal and reputational repercussions

Many industries are governed by strict regulations requiring temperature control. A company found in breach of these standards may face legal penalties, fines, or even the suspension of trading licences. Customers have the right to reject deliveries if they suspect the cold chain has been broken, and may seek compensation. The reputational damage can be equally serious: spoiled products lead to lost trust.

Critical moments in the cold chain

Certain points in the logistics flow present greater risk of cold chain failure. By identifying these vulnerabilities, companies can adopt targeted preventative measures.

The four most critical stages are:

1. Loading and unloading

Transferring products from one controlled environment to another (e.g., warehouse to vehicle) is one of the most hazardous moments. Exposure to ambient temperatures during loading and unloading must be minimised. Best practices include pre-cooling vehicles before loading, using insulated loading bays, and keeping doors open for the shortest time possible.

2. Cold room storage

Even in temperature-controlled warehouses, risks remain. Refrigeration system failures, doors left ajar, or poor stock placement can compromise the cold chain. Constant monitoring, with modern sensors that trigger alerts outside of set parameters, is essential.

3. Refrigerated ransport

Transport introduces unpredictable variables such as traffic, delays, or mechanical issues. The cold chain may be compromised by equipment breakdown, prolonged congestion in hot weather, or driver error (e.g., switching off the cooling system during a stop). Effective mitigation strategies include:

- Certified, appropriate vehicles with sufficient insulation and cooling capacity for the cargo type (e.g., -20°C for frozen goods versus +4°C for fresh produce).

- Telematics and tracking systems that provide real-time temperature data and alerts, allowing quick intervention (e.g., rerouting to a nearby facility).

- Route optimisation software to minimise travel time and avoid risk.

4. Distribution and final delivery

A breakdown in the final link can negate all earlier efforts. Retail environments are particularly vulnerable, as standards may become more relaxed near the customer. For example, if yoghurt is left out during restocking or if a freezer is overloaded and poorly ventilated, temperatures can rise, damaging product quality just before purchase.

Main sectors where the cold chain is essential

For a distributor of nuts and bolts, temperature control is irrelevant. But for others, it is mission-critical. Key sectors include:

Food industry (fresh and frozen)

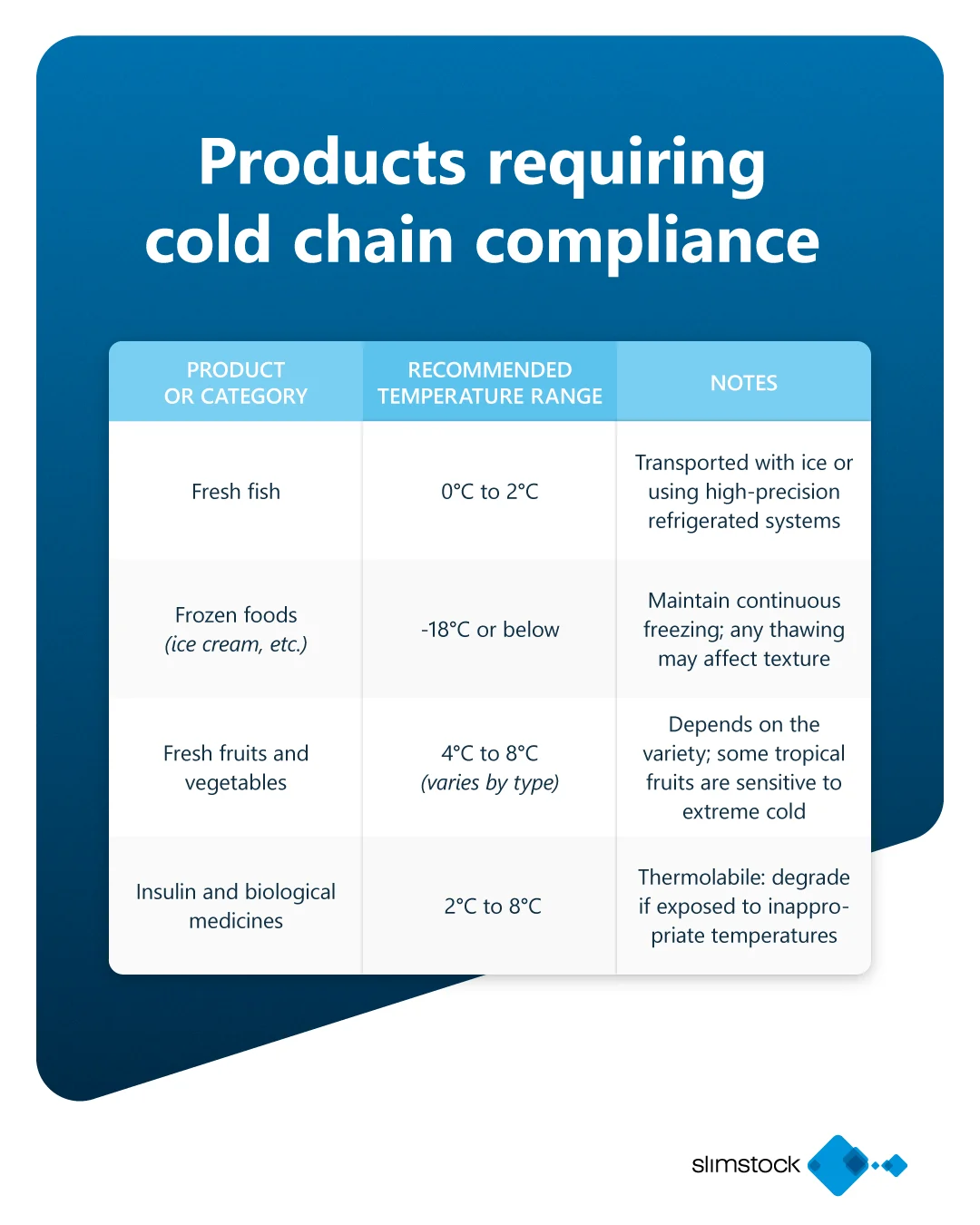

This includes meat, fish, dairy, fruit and veg, ready meals, ice cream, and frozen foods. These must remain within specific ranges to prevent spoilage (e.g., 0°C–4°C for meat and dairy, around -18°C for frozen items).

A break in the cold chain results in immediate quality and safety loss, bacterial contamination (e.g., Salmonella or Listeria) and degradation of flavour and texture. Food companies invest heavily to maintain the cold chain.

Perishable beverages

While many drinks (e.g., soft drinks, wine) don’t need refrigeration, others do, such as fresh milk, unpasteurised juices, probiotic drinks, and craft beers. These must remain between 2–6°C to prevent spoilage.

Pharmaceutical and healthcare sector

Medicines, vaccines, biologics (e.g., insulin, hormones), and lab samples must be kept within tight temperature ranges (typically 2–8°C). For example, some COVID-19 mRNA vaccines required ultra-cold storage at -70°C, posing an unprecedented logistical challenge.

Cosmetics and fine chemicals

It might surprise you, but some natural or organic cosmetics require cooling due to the absence of preservatives. Certain raw materials (e.g., unstable actives) must also be refrigerated until used in formulations.

Conclusion: added complexity, strategic advantage

The cold chain introduces an additional layer of complexity to an already demanding logistics process. It’s not just about transporting goods from A to B, but doing so while maintaining stringent, uninterrupted temperature control across different teams and systems. This requires investment, technology, skilled personnel, and rigorously designed processes.

Yet this challenge is also an opportunity. Organisations that excel in cold chain management not only mitigate risks but also gain a competitive edge. Delivering products in optimal condition, guaranteeing food safety or medical efficacy, and reducing waste due to temperature breaches are clear differentiators. These capabilities enhance brand reputation and build trust with customers who value reliability and precision.