Table of contents

Table of contents- Prepare your supply chain for Chinese New Year 2026: A strategic guide

- Why Chinese New Year matters to supply chains

- 21 essential planning questions to plan for Chinese New Year

- 8 inventory management tips to stay ahead around CNY

- Putting it all together: CNY planning timeline and best practices

- Conclusion

Overview

Chinese New Year (CNY) is one of the most disruptive yet predictable events in the global supply chain calendar, particularly for businesses sourcing from China and wider Asia. With factory shutdowns, labour shortages, freight congestion and extended recovery periods affecting supply chains for up to 40 days or more, early and structured planning for CNY 2026 is essential. This post outlines why CNY has such a significant impact, highlights the key risks to production, logistics and inventory, and provides a practical framework to help businesses prepare effectively. By asking the right planning questions, applying disciplined inventory management and aligning teams across the organisation, companies can protect service levels, control costs and build resilience through the CNY disruption period and beyond.

Chinese New Year (CNY) is one of the most disruptive recurring events for global supply chains. For companies that source products or components from Asia, especially China, the holiday season brings extended factory shutdowns, labour shortages, freight bottlenecks and complex planning decisions.

With Chinese New Year 2026 approaching, it’s important to start planning in advance. The disruption does not last just a few days: when pre-holiday slowdowns and post-holiday recovery are taken into account, supply chains can be affected for up to 40 days or more. Companies that plan early and adopt robust strategies will be far better placed to protect operations, maintain service levels and avoid costly stock-outs.

Why Chinese New Year matters to supply chains

Chinese New Year marks one of the largest annual migrations of people in the world, as millions of workers return home to celebrate with family. For manufacturing hubs in China and across Asia, this results in prolonged factory shutdowns and significant slowdowns in production.

For supply chain teams, the consequences are well known:

- Production halts and extended lead times: Many factories slow down weeks before the holiday, and do nor return to full capacity until well into March.

- Freight rate increases: Demand for ocean and air freight spikes as business rush to ship before closures, often driving up costs.

- Port congestion: Ports tend to become congested before and after the holiday period, increasing dwell times and delaying customs clearances.

- Labour shortages: Warehouses, transport providers and last-mile carriers also feel the pinch, as labour availability drops sharply.

These factors create predictable volatility. Preparing early is not optional, it is critical to protecting service levels and revenue.

21 essential planning questions to plan for Chinese New Year

A useful reference for any inventory and logistics team is the following checklist of 21 strategic questions designed to frame your planning process.

| 1. Have you determined a Chinese New Year project kick off? The earlier you begin, the better off your supply chain will be. |

| 2. Do you know if your suppliers are still accepting orders over the shutdown or will they be fully closed? |

| 3. Are the manufacturing lead times longer in the run up to shutdown because of increased orders? |

| 4. Are your suppliers enforcing different constraints such as minimum order quantities or batch sizes in run up to shutdown? |

| 5. Will shipping times be longer because of increased freight volumes? |

| 6. Do you have the warehouse capacity to handle your increased planned orders? |

| 7. If you need external storage, have you calculated how much and for how long? Have you negotiated terms already? |

| 8. Do you have any suppliers who are not in China but could still be impacted? For example, if you have suppliers in Vietnam, they may also be affected to a lesser extent. Suppliers across Asia may also buy components from China, so they could be indirectly impacted. |

| 9. Are you planning on launching any new products during the affected period? Do you have a sensible forecast in place? |

| 10. Have you discussed with Sales & Marketing if any promotions are planned for Spring 2026? Do you understand the likely impact? |

| 11. Have you thought about how you want to phase the inbound deliveries? |

| 12. Does your warehouse and operations team have the personnel resource to handle the additional volume once the inventory lands at your warehouse? |

| 13. Have you checked with the finance team to understand any immediate budgetary restrictions? |

| 14. Have you considered product lifecycle? If a product is being withdrawn or is going to become obsolete, take into account different MOQs to prevent write-off problems. |

| 15. If you are using historical data, have you modified the forecast to account for demand surges or troughs? |

| 16. Have you validated your forecasts beyond the ordering horizon which includes the shutdown? |

| 17. Have you shared your plans with your supplier to ensure feasibility? Providing a forecast lets the factory prepare for demand after CNY. |

| 18. Have you implemented a quality assurance process? Quality issues can delay shipments before CNY; a proper plan reduces this risk. |

| 19. If you can’t buy ideal quantities, have you determined how to reduce orders? Understand the business impact. |

| 20. Have you considered alternative suppliers? Local suppliers may reduce lead time but could affect gross profit or stock obsolescence risk. |

| 21. Have you confirmed with finance that planned orders and additional costs (temporary staff, extra warehouse space) are within cash flow constraints? |

8 inventory management tips to stay ahead around CNY

To turn strategic planning into action, here you have a set of tactical actions to make planning and execution smoother around CNY:

1. Confirm supplier schedules early

Many suppliers begin winding down their operations 1-2 weeks in advance, and some take several weeks to resume normal output. Failing to confirm your supplier schedule may have you waiting additional 1-2 months to place orders, resulting in outstanding orders.

How can we prevent that from happening? Contact your supplier to break down total lead time into production and transport. This will allow you to ship products before Chinese New Year starts and receive the goods in time.

Also be aware of the start-up period involved. If your supplier’s production does not return to full speed, an additional buffer time might be useful to allow your supplier to pick up speed.

2. Split your items into urgent vs non-urgent

Separate your shipments into urgent items that are time sensitive, and non-urgent items that are not required immediately. Furthermore, factor in product lifecycle changes in and any planned promotions you have in the future. Identifying your high-risks items helps eprevent out-of-stock situations.

Having sufficient warehouse capacity with the right items will help you succeed during the Chinese New Year period. By having the right focus on the right items at the right time, you can prevent overstocking unnecessary items and incurring additional warehousing costs.

3. Plan, place and forecast your orders

Planning plays a key role, especially during peak seasons such as Chinese New Year. Confirm your supplier schedules in advance to give you more flexibility in planning.

In addition to ensuring that your items arrive on time, consider staggering your orders. This helps avoid stock overflow and exceeding warehouse capacity. Additionally, this allows you reduce exposure to surge pricing just to expediate your orders during that period.

Discover how Slimstock’s demand planning & forecasting solution can help you optimise forecasts, prevent stockouts and streamline your supply chain around peak periods.

4. Align your team for tactical operational planning

Neglecting to plan the inbound deliveries is an easy oversight. Smaller, scheduled delivery batches are often easier for warehouse teams to receive and store. There will be enough manpower to receive and unload goods, as well as enough space in the warehouse to store. Aligning teams is important at a tactical level to ensure operational readiness.

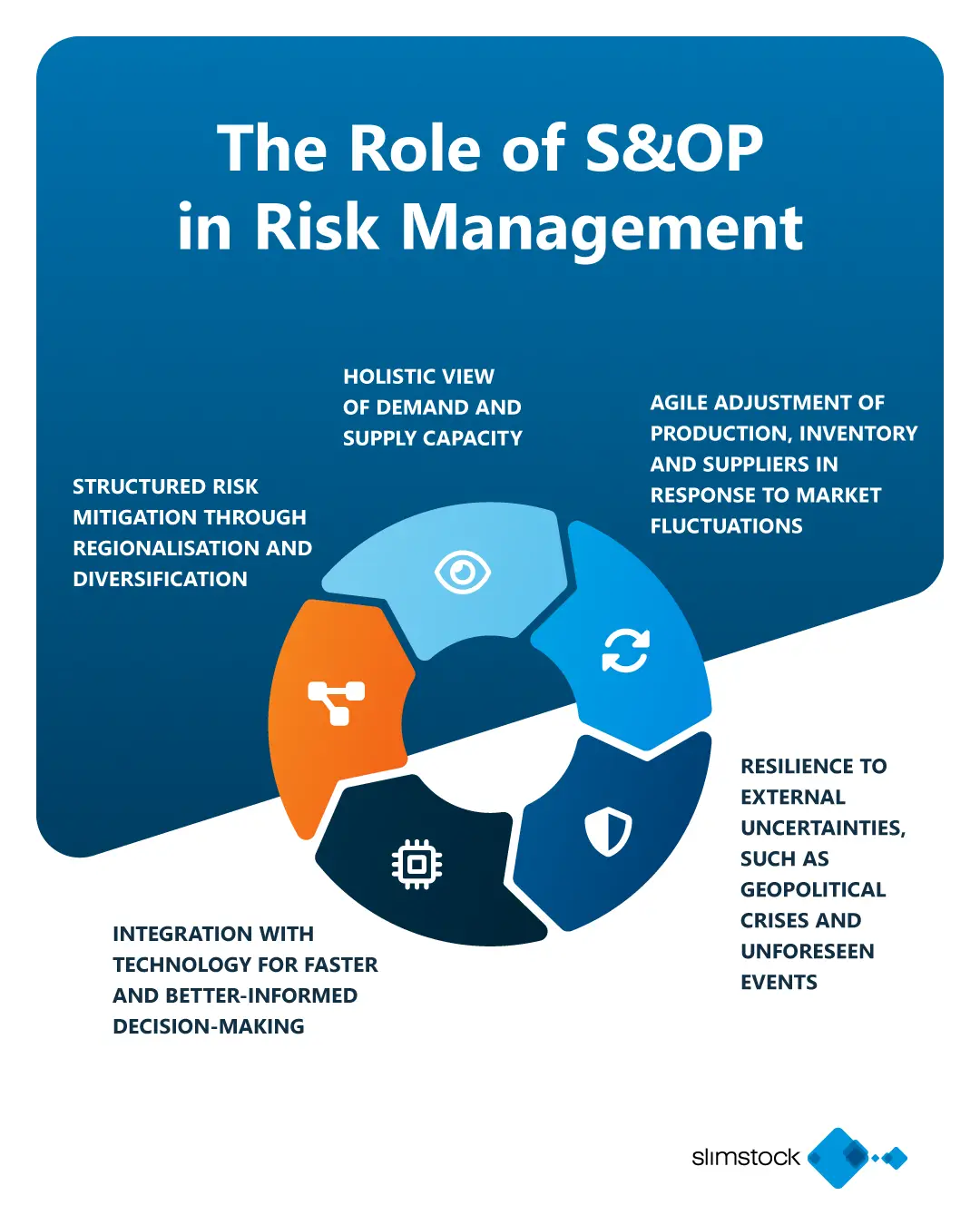

5. Apply S&OP

The S&OP process is a recurring meeting that brings together sales, marketing, operations, finance and other key players to produce an integrated plan, which incorporates and reconciles the views of all functional areas in order to match supply and aggregate demand.

The plan should be continuously monitored and adjusted. In short, S&OP is essential for communication and alignment accross the entire business.

6. Consider external factors

Traditional forecasting merely assumes that each sales period should yield the same results or that each previous period is indicative for the coming period’s volume. If you are using only historical data within your calculations, you might lose sight of what is happening externally. As the Chinese proverb goes: “A year of planning begins in spring.” So if you are planning for the new year, be sure to consider these factors.

Changes in regulations can be a key factor to pay close attention to during forecasting. If you are in the automotive industry, a push in government regulations for clean energy might witness an increase in carbon emission tax, and could result in an increase in future demand for electric vehicles (and its according parts).

How about charges for the retail industry? With the continued rise of ecommerce, traditional brick-and-mortar stores must embrace an omnichannel shopping experience. Successful retailers will have to closely monitor the online situation and adjust your forecast accordingly.

While planning for Chinese New Year, consider all other external factors to ensure that your forecasts adapt to the latest changes.

7. Stakeholder communication

Always aim to communicate all relevant information that could help to streamline your supply chain to all stakeholders. In the supply chain world, the end customers have the whip handle where a little movement in demand travels up the supply chain in an increasing fashion. As we move away from the customers, we see bigger movements.

With Chinese New Year approaching, everyone tries to protect themselves from stock-out situations and missed customers’ orders, by keeping extra inventory to hedge against variability in the supply chain. Hence, huge buffers of inventory are created as a result.

Sharing of forecast (internally and externally) with effective and timely communication helps stakeholders keep abreast of the situation, organise themselves accordingly and reduce inventory waste.

8.Risk management

A successful risk management strategy is one that considers all factors regardless of how small the risk is. Identifying all potential risk and coming up with potencial solutions (both preventive and corrective) can prevent yourself from being in a deer in headlights situations.

One strategy would be to diversify your different sources of supply. If one of your suppliers is facing a service issue, multi-sourcing ensures that you have other sources to rely on. Moreover, having different suppliers with different lead times may provide a better balance to your cost and efficiency, granting you more flexibility and having sufficient inventory to cover through this period.

Flexibility is a key factor of success for Chinese New Year planning. Set aside some time today to identify all potential risks and a playbook on what you can do, allowing you to navigate calmly during potential chaos.

Putting it all together: CNY planning timeline and best practices

To navigate Chinese New Year effectively, your planning should ideally unfold in stages:

Swipe horizontally on mobile to view the full table.

By structuring your planning around these milestones, you’ll be better placed to reduce risks, maintain service levels and safeguard revenue during the CNY disruption period.

Conclusion

Chinese New Year 2026 presents a predictable yet significant challenge. Businesses that are proactive, starting their planning months ahead, asking the right questions and integrating supply chain data into decision-making, will be better equipped to navigate volatility.

By combining strategic foresight with operational discipline, you don’t just survive the seasonal slowdown, you come out more resilient and ready for growth in the post-holiday period. Start planning today.