Stockouts are a very visible sign that you have a supply chain problem. And if you don’t see stockouts in your warehouse or in your stores, you will certainly feel the impact of them on your P&L.

Stockouts have a significant impact on both your margin and your customer experience, which, importantly, aren’t mutually exclusive.

In fact, the worse your stockout issues are, the bigger the issue of negative customer experience becomes. This will ultimately impact your margins and by the time you realise how severe it is, it might already be too late.

At the most basic level, no stock means no sale. But over the course of a longer duration, persistent stockouts will force your customers to go elsewhere. It this turns into a regular pattern, you’ll have serious problems on your hands.

There are a number of reasons you might run out of stock. But all too often, out of stock situations are down to poor planning.

What Is a Stockout ? What Does OOS Mean?

Stockout, or Out of stock (OOS), occurs when a business runs out of inventory for a particular product. It means the product is not available in the warehouse or in store for purchase by customers.

Whether it’s from inaccurate demand forecasting, supply chain disruptions, or unexpected spikes in demand, there are a number of reasons why stockouts might occur.

At best, stockouts will lead to lost sales. At worst, they’ll lead to dissatisfied customers, damage to your company’s reputation, and result in a slip in market position in comparison to competitors who have plenty of stock to sell.

If you can mitigate the risk of stockouts, you’ll be far better protected against both short- and long-term consequences. There are a number of strategies you can take to effectively safeguard against both.

Be it an optimised supply of safety stock, robust demand forecasting, or simply more effective supply chain planning.

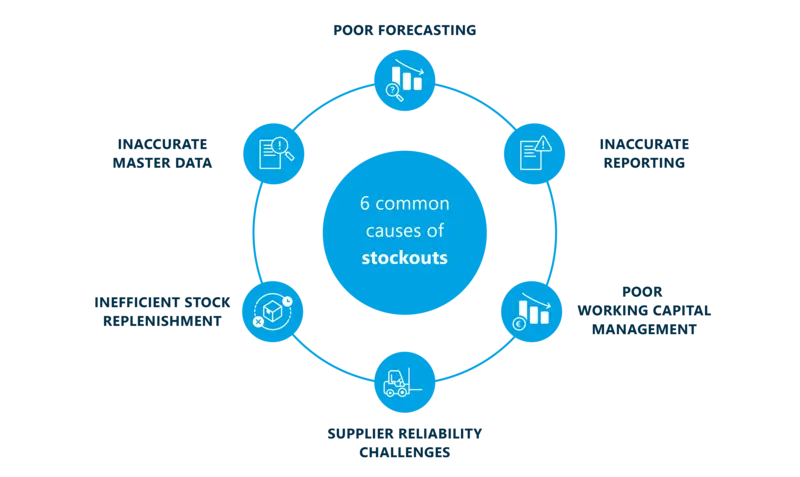

6 Common Causes of Stockouts

Understanding the main causes of stockouts will take you an incredibly long way to combating them. Here’s a handy, non-exhaustive list that might help your business stay ahead of the curve.

1. Item count errors and inaccurate master data

Discrepancies in inventory levels, or simply the cardinal sin of miscounting, might lead your business down the path of overestimating the current on-hand availability of products.

This is certainly far from ideal, and totally avoidable with the right systems in place. But it does happen. A product’s marked as available when it’s not, a customer buys it, and it’s not actually there.

Of course, this also happens the other way. Stock’s marked as sold out on a system, but actually exists in the warehouse. Neither situation is great, but restricting trade for no reason is equally as problematic.

2. Poor forecasting

Inaccurate forecasting can have a number of knock-on effects. Stockouts are simply one of them. But again, having too much inventory could easily be another one, and just as damaging to your business.

Underestimate demand and it’s likely you won’t have enough stock to meet your customers’ orders, making a stockout incredibly likely.

Excess inventory, on the other hand, may even lead to stockouts of other items as your available working capital is squeezed.

3. Inaccurate reporting

Sales data is incredibly valuable to businesses. But only if it’s accurate and timely. Should your data be incomplete, inaccurate, or out of date, your inventory levels will quickly fall out of balance. You’ll also find it far harder to make effective business decisions.

Without this information, anticipating and responding to changes in demand or supply are almost impossible.

And so stockouts rear their head once more. To prevent them, your inventory levels must be well monitored and replenished based on actual sales and demand trends, rather than the whims or best guesses of those with the purse strings.

4. Ineffective working capital management

They say cash is king, and that’s probably not changing any time soon. If you have insufficient capital or poor cash flow management, your ability to purchase inventory to meet demand will suffer.

Often, you’ll find it tied up in non-liquid assets, or cash shortages across the business. As a result of these two issues, the procurement of inventory could be delayed or limited and that’s an issue that needs addressing, quickly.

Left to its own accord, you’ll find stockouts are unavoidable.

5. Supplier reliability challenges

Every business in the supply chain suffers from delivery problems at some point in their existence. It might even be a regular occurrence.

Experiencing delays, damages, or errors in your deliveries will disrupt the availability of goods and may lead to stockouts. Especially if it’s a regular occurrence.

Of course, if your inventory’s delayed by a long duration, or fails to arrive completely, you may not have the inventory on hand to replenish before the next shipment arrives.

Whether it’s a transportation delay, customs clearance problems, or just supplier capacity constraints, the reasoning behind the issues need addressing before they impact your product availability and bottom line.

6. Inefficient stock replenishment

Smooth processes will grease the wheels of many issues in your business. On the flip side, ineffective or slow replenishment processes can result in stockouts.

This is especially true if your customer demand fluctuates throughout the year based on seasonality or trends.

To avoid the possibility of stockouts, focus on placing orders promptly and reducing lead times wherever possible. Communication with both your internal teams and supply chain partners should be top of the list of priorities. The better you communicate, the better the business will run.

How Do Stockouts Hurt Your Business?

Stockouts are an expensive problem. Right away you’ll find lost sales revenue due to customers being unable to buy your products.

As mentioned above, this will also lead to a less than satisfactory experience for your customer. Whether it harms the brand’s reputation depends on the severity of the issue, but if they can find a more reliable place to shop, they will.

The loss of customer loyalty isn’t a great strategy to pursue for long-term business success. Especially if those once loyal customers become loyal to your fiercest competitors.

It’s highly likely your operational costs will rise as a result of stockouts.

Simply dealing with the problem will require additional resources and efforts you might not have the capacity to focus on. Maybe it’s expedited shipping, rush orders, extra staff hours, new promotional campaigns, stockouts of other products in your inventory, or higher marketing spend – the list is almost endless.

You might even have to offer discounts, making any sales you do complete less valuable to the business. And missing cross-selling or upselling opportunities is a natural follow on.

A common solution considered by many businesses is increasing the working capital investment in safety stock to make sure they never experience a stockout again. But of course, that has its own perils. Your carrying costs will rise, as will the risk of excess and obsolescence.

8 Top Tips for Preventing Stockouts

Whilst stockouts are sometimes unavoidable, you can take actionable measures to make them far less likely.

Here are some time-tested methods to do just that.

1. Keep your master data clean

Audit your sales data regularly and make sure you master data’s on the money. It needs to reflect changes in product attributes, suppliers, and lead times, and make sure you have accurate inventory management at every stage.

Implementing data validation checks is a sure-fire way to identify and correct errors that might arise in your data and give you every chance of ensuring its integrity and reliability.

2. Plan promotions & special offers with precision

Reactively putting other, similar items on sale to avoid your customers’ disappointment isn’t a strategy that will pay off in the long-term.

Predictive analytics and historical sales data can help you forecast the impact of promotions and allay fears of being too reactive to the market or a lack of inventory availability.

Precise inventory allocation and replenishment is a must.

The better your sales and planning teams collaborate with marketing, the better coordination you’ll find in promotional activities.

By minimising stockouts, you’ll maximise sales opportunities.

3. Optimise multiple location planning

Demand-driven allocation strategies will help your business distribute inventory based on demand patterns and service level requirements with a regional focus.

This is particularly useful for companies that operate across locations with varying demand patterns.

Network optimisation models can help your business determine optimal inventory levels. Minimising stockouts while maximising inventory turnover across different geographies presents its own challenges. Being one step ahead will help you limit the likelihood.

4. Collaborate with suppliers to optimise lead time reliability

As mentioned above, effective communication with suppliers is non-negotiable for your company’s success.

Try to establish service level agreements (SLAs) with your suppliers that define lead time expectations. If possible, try and instil penalties for deviations and incentivise on-time deliveries.

Try to help your suppliers understand the knock-on effects of stockouts and work collaboratively with them to eradicate the possibility.

5. Enhance demand forecasting and planning

If you can implement demand sensing techniques that utilise real-time data and advanced analytics, you’ll be in a far better position to adjust your forecasts accordingly and accurately.

Forecasting errors are a huge reason for stockouts.

Regular demand validation reviews will help to incorporate market trends, seasonality, and promotional activities into your forecast models.

6. Diversifying suppliers and partnerships

Suppliers will let you down, despite their every insistence to the contrary. On occasions like this, you should prioritise identifying alternative suppliers who won’t.

They might well be in different locations or industries, but the more you can talk to and explore their offerings, the better you can mitigate the risk of disruptions.

Using a single source of supply is often a worry when you want to guarantee reliable supply to your customers.

Plan collaboratively, forecast together, and share risk wherever possible.

7. Establish safety stock levels and reorder points based on data-driven analysis

Just buying more stock isn’t the way to ensure availability. You need to be measured and calculated.

To do this, conduct statistical analysis of demand variability, lead times, and service level targets.

This will help you better identify optimal safety stock levels and reorder points. You’ll also be able to better balance your inventory holding costs and reduce the risk of stockouts.

8. Embrace advanced supply chain tech

AI-powered supply chain planning tools can help you deploy advanced algorithms for better demand pattern analysis. It’s a lot better than sticking your finger in the air, or guessing based on last year’s figures.

Enterprise systems such as ERP, CRM, and POS systems will help ensure a seamless data flow and real-time visibility. And in the supply chain, visibility is everything.

Stockouts FAQs

What is a stockout?

A stockout, or Out of Stock (OOS), happens when a business runs out of inventory for a particular product, meaning it’s not available for purchase by customers.

What causes stockouts?

Stockouts can result from inaccurate demand forecasting, supply chain disruptions, unexpected spikes in demand, poor inventory management, and inefficient working capital management.

How do stockouts impact a business?

Stockouts lead to lost sales revenue, dissatisfied customers, damage to the company’s reputation, increased operational costs, and missed cross-selling or upselling opportunities.

How can businesses prevent stockouts?

Businesses can prevent stockouts by keeping master data clean, planning promotions with precision, optimizing multiple location planning, collaborating with suppliers, enhancing demand forecasting, diversifying suppliers, establishing safety stock levels, and embracing advanced supply chain technology.