Table of contents

Table of contents- What is Demand Forecasting? A Comprehensive Guide

- Demand forecasting cheat sheet

- Reliability is the key word here

- How can you improve your forecast process?

- What is demand forecasting?

- Why is demand forecasting so difficult?

- What are the benefits of demand forecasting?

- The demand forecasting process

- Here are a few pointers:

- How to build your own demand forecast

- How can you improve the accuracy of your demand forecasts?

- Demand forecasting takeaways

- Demand forecasting with Slim4

- Demand forecasting FAQs

Demand forecasting cheat sheet

Making good business decisions can be the difference between profit and loss. Between surviving and thriving. To stand the best chance of making the right decisions, effective demand forecasting is the best tool you can have in your armoury.

It doesn’t matter whether you’re looking at inventory levels, or the wider scope of your entire business, demand forecasts are crucial. Demand forecasts underpin everything from setting annual budgets to tax planning.

Reliability is the key word here

Any business can take a stab in the dark. But those companies are unlikely to be around for long. Those who place forecast reliability at the top of their considerations will be the ones who see long-term success.

The main objective in product demand forecasting is to attain a robust picture of future demand.

That much is simple.

But, the difference in results between those with accurate forecasts, and those without, is huge.

Research suggests that businesses with accurate forecasts see significant performance improvements against that struggle to anticipate what’s on the horizon.

To put it in numbers, 79% of businesses with high-performing supply chains achieve above-average revenue growth.

Despite the overwhelming evidence for the importance of demand forecasting, however, a staggering 69% of companies admit to having limited visibility over their supply chain.

If you’re keen to avoid becoming one of those negative statistics, keep reading.

How can you improve your forecast process?

The million-dollar question. It might even be worth more than that.

Regardless of the exact figure, improving your approach to demand forecasting will make you money. It’s as simple as that. So over the next few paragraphs, we’ll look to answer it as well as we can.

We’ll explore::

- How to define demand forecasting in your business.

- What steps you should include in your demand forecasting process

- Which features are present in all great forecasts

- How to spot a good demand forecast

- What tools & techniques do you need in your demand forecasting toolkit

What is demand forecasting?

Forecasting can mean different things to different teams.

However, when we talk about “demand forecasting”, we’re talking about the method of estimating the future demand for a product or category. As such, this is a critical part of your wider demand planning and S&OP process.

To create an accurate demand forecast, you’ll need to analyse historical data, market trends and any other indicator at your disposal to make your predictions as informed as possible.

The aim with those predictions is to make better decisions. Decisions about order quantities, production, pricing and marketing. However, the list could go on..

There’s no use guessing you’ll need “a lot” of product A. You need an estimation as close to the actual number as possible.

Doing so will mean you can avoid overstocking, stockouts and loose production schedules.

And, in a world where your customer’s number one, failing to align your internal efforts to their demand is risky business.

Why is demand forecasting so difficult?

For some businesses, guessing what their customers might want in 6 months time is like trying to predict winning lottery numbers.

This is why it’s so important for you to use every tool at your disposal to improve your chances.

But with so many variables that can affect demand, which factor do you focus on the most?

How do you gauge demand in emerging markets or for new products?

And what if the master data you’re relying on is incomplete or unreliable? What if things change and your data becomes quickly out of date?

The burning questions above implore you, and any business looking for an edge, to continuously gather and analyse as much data as you can to improve the decisions you make.

Demand planning isn’t something you do in January and then rest easy. It’s an ever-present, ever-important activity which should form a huge part of your planning process.

After all, if you don’t understand your customer’s behaviour today, how can you predict what they’ll want tomorrow?

What are the benefits of demand forecasting?

If you need more evidence of the benefits of demand forecasting, see below.

The positives are plentiful and aren’t limited to bottom-line calculations or simply staying afloat.

Not that that’s not reason enough to take your demand forecasts seriously.

1. Better inventory management

The more accurate your demand forecasts are, the better you can manage your inventory levels. Which means greater efficiency, less waste, lower costs and higher profits.

2. Improved production planning

Good demand planning can dramatically increase your ability to match production with demand.

Doing this will give you a greater ability to manage time and resources and further minimise waste.

3. Joined up planning

Are all your teams singing from the same hymn sheet? By providing a unified picture of future demand, you can ensure that your sales, marketing, finance and operations teams are all working from the same numbers.

4. Improved supply chain management

It’s hard to make good supply chain management decisions about what materials you need, which suppliers you work with and even where you should invest your time without a clear picture of where your business is heading.

A good demand forecast will provide your team with the clarity and direction they need to take the best supply chain actions.

5. Strengthen your financial position

The better your demand forecasts, the better your ability to forecast cash flow, revenue and overall financial health. Something which should be music to the ears of your finance team!

6. Greater awareness of risks and opportunities

Blind luck will only get you so far. Knowing when to stick and when to twist will make moves into new opportunities easier and more fruitful.

It’ll also help you highlight risk sooner than other businesses, giving you a constant edge over your competition.

7. Unlock opportunities for continuous optimisation

With the right insights, setting meaningful KPIs also becomes easier. More importantly, you’ll have a deeper insight into the levers you can pull to hit your business goals.

8. Empower your people

Lastly, there’s no one you employ that can’t improve their success with a better forecast. That extends to those stakeholders outside the perimeter too, like customers and suppliers.

The greater transparency you have, the more you’ll make informed decisions, reduce costs and improve efficiency, which can only result in better profits.

The demand forecasting process

Hopefully, you are fully sold on the advantages of demand forecasting. But now it’s time to take this to the next level. In the next section, we will explore how you can optimise your approach to demand forecasting.

Like many things in the supply chain, implementing the right process is the best place to start. But, to create a seamless and successful demand forecasting process you need to consider the following steps:

1. Define your objective

What’s the purpose of your forecast?

Will it be used for financial planning? Inventory management? Sales planning? Marketing activity? Or a combination of all of the above?

2. Think about who’ll use the forecast

Your CEO, whether that’s you or someone else, will need different levels of detail in the forecast than your planning team.

CEOs by nature need high-level insights. They need big-picture analysis to make decisions about the business for the next 12-18 months. This means they need a demand forecast that captures a broader group of products, business division or time horizon.

The demand planning team however needs to analyse a forecast in microscopic detail. They need enough information to make short-term decisions about replenishment, order quantities and inventory allocation.

3. Define the characteristics of your forecast

Once you know who’s going to use your forecast, you’ll have an increased ability to define it.

To make it as useful as it can possibly be, make sure you look at:

- Timelines

- Forecast hierarchy

- The types of product

- The various locations and sales channels you need to plan

- Measurement units, like sales turnover, volume or order lines.

4. Select the best forecasting system for you

There’s a number of different ways to forecast demand. We’ll look at them all in detail later on, but consider:

- The availability of data

- The planning horizon

- The complexity of demand

- The level of accuracy needed

- The knowledge, expertise and resources you have available

- The time needed to create the forecast

5. Capture all the data you can

Once you’ve completed the steps above, you can think about data.

Whether you look within (internally, not existentially), externally or from the market, the more data you have, the better equipped you’ll be. But you also need to know which data to consider and which to ignore.

Historic sales, customer behaviour, market trends, seasonality, supplier forecasts, big data sources are all useful. But some may be more so than others.

Collect the right data and you’ll be more likely to see higher profits and beat your competition.

What does a good demand forecast look like?

The harsh truth is that forecasts, by their very nature, are at best, guesses. Naturally, the more data you have, the better those guesses are.

But there’s still an abundance of factors that can change the landscape.

Fail to highlight these factors and they’ll quickly thwart your forecast in front of your very eyes.

So how do the best businesses in the land forecast demand? How do they continually assess what their customers want and align their efforts to that end?

Here are a few pointers:

1. Continuous validation unpins the demand forecasting process

Market insights can take statistical forecasts based on historic sales data, and give them the gift of foresight.

Say you sell office equipment and sold out of laptop stands continuously over lockdown, does that mean you’ll continue to now?

Or does the fact people are returning to office life mean sales will slow down?

Historic sales data can give you a snapshot, but more often than not, it’s not the full picture. The most successful companies substantiate their forecasts with insights from the market.

By doing so, they instil a validation process. Done right, this will involve various teams and be a consensus of best practices.

2. It’s understandable and easily explainable

A demand forecast shouldn’t be so complex that no one understands it. Quite the opposite. It should be easy to understand by any of the stakeholders.

Further to this, it needs to be explainable. Easily explainable. Both the insights within it and the desired actions arising from it.

3. It should be recordable and measurable

Fail to record the accuracy (or rather the error) of your demand forecast and you’ll never know whether you were out by 0.5% or 50%.

And that’s important: 0.5% is a wild success. 50% is a total failure.

Knowing which one you were closer to will help the next time you have to create one. Which should be soon.

The more you measure your forecast, the better you’ll be able to tweak and make changes to it.

Errors you don’t know you’re making will be repeated again and again.

4. Every demand forecast should have an owner

Every forecast you create must have an owner. Someone who is accountable for its success and accuracy. Without an owner, it’s more likely to fall flat on its face than create a competitive advantage.

Remember, the decisions you make on the back of this forecast could be the difference between success and failure.

If you’re the one who’s making those decisions, you’ll take ultimate responsibility if they’re wrong.

How to build your own demand forecast

There are many different models you can contemplate when thinking about designing your own demand forecast. Naturally, there are pros and cons to each one. In some cases, combining them can give you the best results.

In the next section, we will explore some of the most common demand forecasting approaches.

Which demand forecasting models should you apply?

1. Time-series analysis

What can sales from the last 12 months predict for the upcoming year? That’s the premise of the time-series analysis.

As one of the most common methods of statistical demand forecasting, this is a handy one to get your head around.

It looks for patterns in data which might be replicated moving forward. It also allows you to see what might’ve influenced these patterns and make forecasts more accurate.

There’s more than one type of model in this analysis function too. There are moving averages, exponential smoothing, and autoregressive integrated moving average (ARIMA) models.

Each model uses a different method to analyse its data. Which one you need should be paid close attention to, to increase its potential success.

2. Judgement-based demand forecasting

How likely are the people in your company to make great predictions about future demand? The answer to that will depend on the strength of their capability and differ by company, team or even person.

One of the biggest challenges in effective demand forecasting is that the data can only tell you so much.

If you’re a new business, or releasing a new product in a new market, there’s almost certainly a deficiency of data you can rely on.

That’d make judgement based forecasting worth considering.

The same can be said about markets with high levels of disruption, given the limited ability of machine learning and statistical modelling in unknown areas.

If your demand forecasting approach ensures that market insights are actively gathered, you will be better informed and therefore have a higher chance of creating an accurate forecast.

To give yourself the best chance of succeeding in judgement-based modelling, you’ll need to research a huge number of areas.

That’d probably include market research, competitor analyses, speaking with customers, your sales team and even exterior market experts.

Considering this approach might help you analyse factors which aren’t picked up by other models.

But as with every other model, there are drawbacks to consider.

Are the people making these judgements totally impartial? Are they making decisions solely based on data or with prejudice from their own feelings about products or markets?

Equally, can you repeat this process? It’s often very difficult to produce the same numbers with different stakeholders, making judgement-based forecasting hard to replicate on a long-term basis.

3. Causal Analysis

Causal analysis identifies the cause-and-effect relationships that impact demand. It involves analysing data to show how changes such as price, promotions, or economic indicators, can change demand.

Causal analysis can be used to make both short-term and long-term forecasts and often involves the use of experiments to test the causal relationships between variables.

4. Regression analysis

Regression analysis explores the link between demand and multiple other variables. Whether that’s price, market share, environmental or market conditions.

This type of analysis allows you to assess how changing one of the variables might impact demand. And therefore optimise them. Which will help your supply chain planning.

What’s the difference between causal analysis and regression analysis?

One key difference between causal analysis and regression analysis is that causal analysis tends to focus on specific variables, while regression analysis takes a more comprehensive approach and considers multiple.

Another difference is that causal analysis often involves experimentation for the benefit of testing. Regression analysis is typically based on historical data and statistical modelling.

5. Machine learning

The capabilities of machine learning and AI is rather impressive.

Using these advanced techniques to analyse past data and make informed decisions about future demand could save you time and money.

Giving historical data to a machine learning platform can draw out patterns and make estimating future demand a lot easier.

Especially where more traditional methods might not cut the mustard.

If you’re in a business where the industry changes sharply and without warning, underpinning your forecast with machine learning could be incredibly useful. AI is defined as such because it continues to learn.

And so in theory, the accuracy of your forecast with machine learning should improve over time.

There are pitfalls of course. Not having enough data to analyse can result in a limited forecast. Relying too heavily on data which is incomplete or not accurate could result in failure.

How can you improve the accuracy of your demand forecasts?

Choosing the best forecasting model for you, will help make them more accurate, and therefore help you make solid, informed business decisions.

But even then, there are steps you can take to unlock rich insights and bring greater clarity to your business.

Our next section will focus on how you can further elevate your demand forecasts.

Aggregation vs disaggregation

The rise of data and its use in business is monumental. But as any Data Scientist will tell you, having the data and using it are two very different things.

We often talk about the importance of having specific stocking strategies for every SKU. It’s understandable then, you might think the same thinking could help you forecast, too.

Only that’s not always the case.

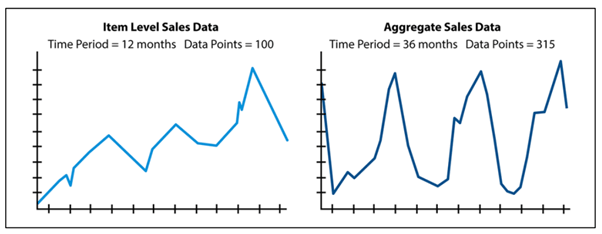

The below graph explains why aggregation can help in your forecast.

The reason aggregation can help improve your demand forecasting model is because of the power of larger data sets. The law of large numbers dictates the larger your sample size, the more representative it is of the wider population.

Taking sales data from one village will never relate to an entire country. But take that same data from 5 cities within the country and it’s far more likely to correlate.

Use find more data points and you will cut out the noise from anomalies. That means you’ll find more patterns and a greater ability to account for variables.

Likewise, imagine you are forecasting demand for a SKU that has recently been launched. You are unlikely to have a complete data set. However, if you aggregate the forecast from the category level, you are likely to attain a better idea of how demand will evolve for the SKU in question.

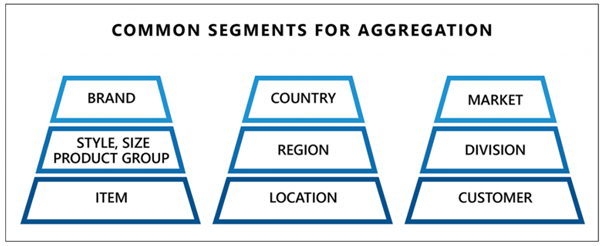

Here are a few common examples of how you can aggregate your demand plans:

A huge positive of using aggregation is that your data is less likely to be influenced by singular irregularities.

On the flip side to that, however, not paying attention to outliers which may ordinarily stand out, you may miss important data that could impact your business.

Decide to use aggregation on a case-by-case basis, and you won’t go far wrong.

How can disaggregation help you?

Sure, aggregating data can be very helpful. However, you will still need granular-level insights to understand the demand patterns for each product individually.

Typically the lowest level of granularity in demand forecasting refers to the disaggregating the demand forecast by the SKU location combination or even by customer.

The former can help you to optimise your allocation and replenishment to ensure you meet forecasted demand with the minimal level of stock.

The latter can help you identify which customers are most profitable, which have growth potential and which only account for a small proportion of forecasted demand.

And why should you care about this? Well, this invaluable insight will help ensure you invest your time, money and energy in the areas of your business or the customers that add the most value.

How can ‘time buckets’ create more reliable and robust demand forecasts?

Another method of aggregating your demand forecasts is by time.

Monthly forecasts tend to be more reliable than daily or weekly forecasts. The reason for that is they tend to be far less volatile. There may well be differences week to week or even day to day in how many products are sold, but over the course of a month, these are ironed out.

Here are a few reasons why demand forecasting in monthly buckets is more reliable:

1. Monthly forecasting’s larger bucket better absorbs customer volatility.

If someone normally orders from you in the first week of the month, but then orders in the second week, that’d massively disrupt your data if modelled by the week.

On a monthly basis, that deviance would be absorbed and your data just as useful.

2. Monthly forecasting can be more efficient

Creating weekly forecasts can be far more time-consuming and resource-intensive than creating monthly forecasts.

With monthly forecasts, you may need to gather and analyze data once a month, whereas with weekly forecasts, you may need to repeat the process four or five times a month, depending on the number of weeks in the month.

3. Monthly timeframes handle seasonality better.

Every company has slow weeks. Imagine you’re in a market that slows down for Christmas, the Chinese New Year period or perhaps even during the summer season.

In weekly forecasting models, these quiet weeks can produce gaps which have a greater influence over your demand forecast. Consequently, you end up with a far more nervous forecast. This in turn, is far more difficult to plan from.

Is there any use for weekly demand forecasting buckets?

Yes. There is. But you need to know when and how to use it effectively.

Weekly forecasting needs more effort than monthly, but where patterns arise that dictate irregular, but repetitive, sales activity depending on the week within the month, it’s worth thinking about.

Here’s a nice example:

| Week | Days in Week | Sales | Sales/Day |

|---|---|---|---|

| 1 | 5 | 324 | 64.8 |

| 2 | 7 | 132 | 18.6 |

| 3 | 7 | 40 | 5.7 |

| 4 | 7 | 34 | 4.7 |

| 5 | 4 | 10 | 2.5 |

As you can see in this image, 60% of sales come in the first week of the month.

By using data showing outcomes like this in a weekly forecasting model, you are likely to be more responsive and can take more proactive steps to align supply and demand more closely.. This means you can optimise inventory levels, improve revenue management and therefore profits.

Equally important uses for weekly forecasting models might be if you have a customer who also uses a weekly model. Increasing the link between you and them can be priceless in increasing accuracy and aligning both company’s efforts.

Demand forecasting takeaways

Importance of Demand Forecasting:

- Central to making informed business decisions.

- Helps in setting annual budgets, tax planning, and determining inventory levels.

- Can heavily impact profitability and long-term success.

Reliability is Crucial:

- Forecast accuracy is key for longevity in business.

- Research indicates a strong correlation between accurate forecasting and above-average revenue growth.

- Shockingly, 69% of companies have limited visibility over their supply chain.

Definition of Demand Forecasting:

- Estimation of future demand for a product or category.

- A holistic approach incorporating historical data, market trends, and more to inform predictions.

- Not just about vague estimations but precise predictions to avoid overstocking and other inefficiencies.

Challenges:

- Many variables can affect demand, making predictions difficult.

- Emerging markets and new products introduce additional uncertainty.

- Continuously updated, accurate, and comprehensive data is vital.

Benefits of Demand Forecasting:

- Inventory Management: Precise forecasting leads to optimal inventory levels.

- Production Planning: Aligns production with demand.

- Unified Planning: Ensures all teams are aligned.

- Supply Chain Management: Informs decisions about suppliers, materials, and investments.

- Financial Strength: Better demand forecasts can provide clearer financial projections.

- Risk Management: Helps identify risks and opportunities early.

- Continuous Optimization: Provides insights for setting meaningful KPIs.

- Empowerment: Offers clearer insights to all stakeholders, improving overall decision-making.

Optimizing the Demand Forecasting Process:

- Define Objective: Understand the purpose of your forecast.

- Identify Users: Different users require different levels of forecast detail.

- Define Forecast Characteristics: Consider timelines, types of products, locations, sales channels, and measurement units.

- Choose the Right System: Consider data availability, complexity, required accuracy, resources, and more.

- Capture Comprehensive Data: Use internal, external, and market data for the most accurate forecasting.

This handbook underlines the immense value of demand forecasting in the successful operation of businesses. Effective demand forecasting not only supports optimal inventory and production planning but also provides a strategic advantage in navigating future market conditions. It is essential for businesses to prioritize reliability and accuracy in their forecasts to reap the numerous benefits highlighted.

Demand forecasting with Slim4

There’s a lot of information in this article which will hopefully really help in your demand forecasting. But there’s a lot to consider.

Which is where Slimstock, and Slim4 can really help.

Do you find spreadsheets limiting?

Are you trying to anticipate the demand of hundreds or thousands of SKUs?

Are you attempting to plan multiple demand streams and only have a small team to help?

The Slim4 engine can help you out.

Find out how, by clicking here.

Demand forecasting FAQs

What is demand forecasting?

Demand forecasting is the process many businesses use to estimate the future demand for a product or category. By accurately anticipating your customer’s requirements, demand forecasting can help you to optimise operations, production, and supply chain activities.

What are the demand forecasting best practices?

You can improve the accuracy and effectiveness of their demand forecasting by taking some of the following steps:

- Combine multiple demand forecasting approaches to attain the best picture of future demand

- Enrich your demand forecast with external market intelligence

- Optimise your Masterdata to ensure the basis of your demand forecast is robust

- Continually monitor & adjust your forecast

- Engage the wider business throughout the demand forecasting process to capture insights and validate your assumptions

- Measure and review forecast errors to identify areas for improvement

What are the main demand forecasting methods?

There are many different ways you can forecast demand. However, the main demand forecasting methods include Judgement-based demand forecasting, Time-series analysis, Regression analysis and Machine Learning.

How can demand forecasting software help me make better decisions?

Demand forecasting software can help you and your team in a number of ways. For example, demand forecasting can help improve forecast accuracy, increase efficiency and enhance collaboration. However, it is important to note that any technology such as demand forecasting software should underpin the people and processes throughout your supply chain.