Table of contents

Table of contents- What is S&OP (Sales and operations planning)?

- What is S&OP (Sales and operations planning)?

- But …. Do we really need S&OP?

- S&OP objectives

- How to implement an S&OP planning process

- The 6 steps for the implementation of an S&OP process

- The S&OP concepts

- Challenges during S&OP implementation

- Benefits of S&OP planning

- Conclusions on sales and operations planning

- Optimise the S&OP process with Slim4!

- FAQS about Sales & Operations Planning

Overview

Sales and Operations Planning (S&OP) is a monthly, cross-functional business planning process that aligns strategic objectives with day-to-day operations by balancing demand and supply. It uses a structured cycle, including steps like data collection, demand review, and executive meetings, to improve forecast accuracy, communication and agility, ultimately leading to a single, actionable demand plan and better customer service while minimizing risk and maximizing opportunities.

That we live in a world of constant change is not new, what is probably new is the speed of change. In general, humans do not like change very much, we are energetically efficient and change forces us to make an effort, to leave our comfort zone, our known zone, a place where we also feel fit, capable and secure. But in a hyper-connected world you cannot just choose not to change. You have to learn to navigate.

Change brings complexity, uncertainty and unpredictability and companies that aspire to operational excellence deal with these factors by being more agile, faster, more flexible and resilient.

Today, more than ever, you must excel in these qualities if you want to remain competitive.

But what does this have to do with S&OP? Basically S&OP allows us to be organizationally prepared to deal with the known and the unknown.

Imagine the following situation, you are a chef in a 4 Michelin star restaurant and your job is to manage your talented kitchen team to deliver the most fantastic and tasty menu in town. Your job is to ensure that the work is carried out in the most efficient and coordinated way possible, the dishes must be of the right quality, at the right temperature and at the right time. Nothing can go wrong, you can’t serve if the sauce isn’t ready and you can’t serve if you don’t know which side dish goes with the main course. Will your team be able to improvise if a single ingredient is missing?

To deliver the desired menu, the kitchen team needs a leader, the chef, a coordinated team, precise planning of the ingredients, and the order of the dishes as well as clear communication of what needs to be done and how, all for a common goal, a menu that meets the expectations of the diners.

What is S&OP (Sales and operations planning)?

S&OP (Sales and Operations Planning) is a business planning that aligns strategic business planning with day-to-day activities at the operational level.

Through a structured work process, which is repeated cyclically every month, teams communicate and collaborate with each other to generate and maintain a single demand plan for the entire company. This allows teams to always be organised and prepared for changes and to make quick and agile decisions.

S&OP allows us to identify unexpected changes, either because of new business opportunities or because what we thought would never happen finally happens.

Who expected the COVID crisis to happen or to win a big project worth many, many thousands of euros?

But …. Do we really need S&OP?

Companies exist fundamentally because they have customers, as well as products, services and people. Each customer is unique and we win and/or keep them when we are able to offer them value, their value. Approached pragmatically, value to the customer is what they are willing to pay for, including the shopping experience and the quality of our relationship with them.

Companies establish their value strategy, i.e. they strategically decide how they want to approach their customers and what value proposition they are going to offer them. Remember the famous Michelin menu?

But how can we make that proposition effective? Isn’t it our day-to-day operations that deliver that value?

S&OP is a tool that enables us to deliver effectively by improving the way we engage with our customers.

S&OP objectives

There is no journey without a goal, and every business initiative has a purpose.

Companies that choose to adopt an S&OP planning process begin a journey towards transformation in order to drive growth and thus remain, at the very least, competitive.

Specifically, some of the main objectives of S&OP planning could include:

- Integrating long-term planning into business processes

- Aligning demand and supply

- Balancing expected demand and company responsiveness

- Improve the accuracy of our sales forecasts (forecast accuracy) and the way we improve them (Forecast Value Added).

- Improving communication and collaboration within and outside the organisation

In essence S&OP prepares teams to,

- Minimising risks

- Maximise business opportunities

- Making agile decisions based on profitability rather than volume

The ultimate goal is to create a single demand plan that captures the company’s strategic objectives and turn it into an actionable plan at the operational level that allows us to run our daily operations in a sustainable manner.

How to implement an S&OP planning process

An S&OP planning consists of cycle structured yet flexible meetings, formed by multidisciplinary teams, from different functions of the company, Sales, Marketing, Operations and Finance.

Each process meeting follows a predefined agenda and has an objective aligned with the expected outcomes of the S&OP process. To achieve the results we have the levers or drivers and we use KPIs to measure and evaluate progress in our achievement of objectives

For example, during a meeting with product managers our objective would be to reduce the risk of obsolescence in next year’s new product launches, our drivers to achieve this would be to improve the knowledge of the customer segment we are approaching and to improve product introduction channels. Our preferred KPIs could be % success of a channel entry or % overstock on new products. With monthly measurement and tracking, we could monitor the outcome of our actions and apply corrective measures if necessary.

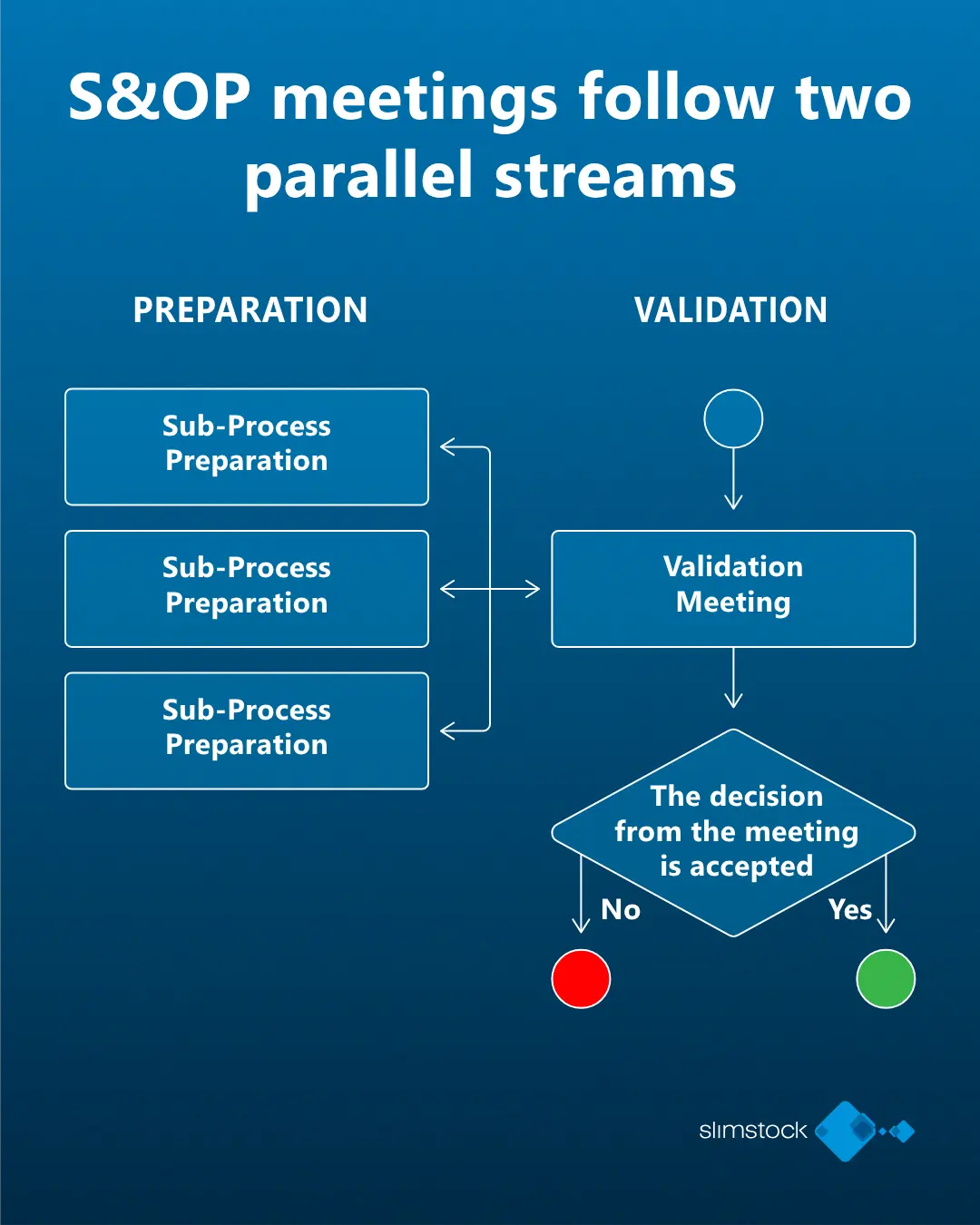

The S&OP meetings follow two parallel streams.

For an S&OP process to work, it requires a great deal of perseverance, discipline and involvement during planning meetings. One way to ensure this is to establish a few golden rules. For example, go prepared to the meeting, actively participate or share information. A positive attitude, open-mindedness and collaboration go a long way in making meetings effective, reaching agreements and results at the end of the session.

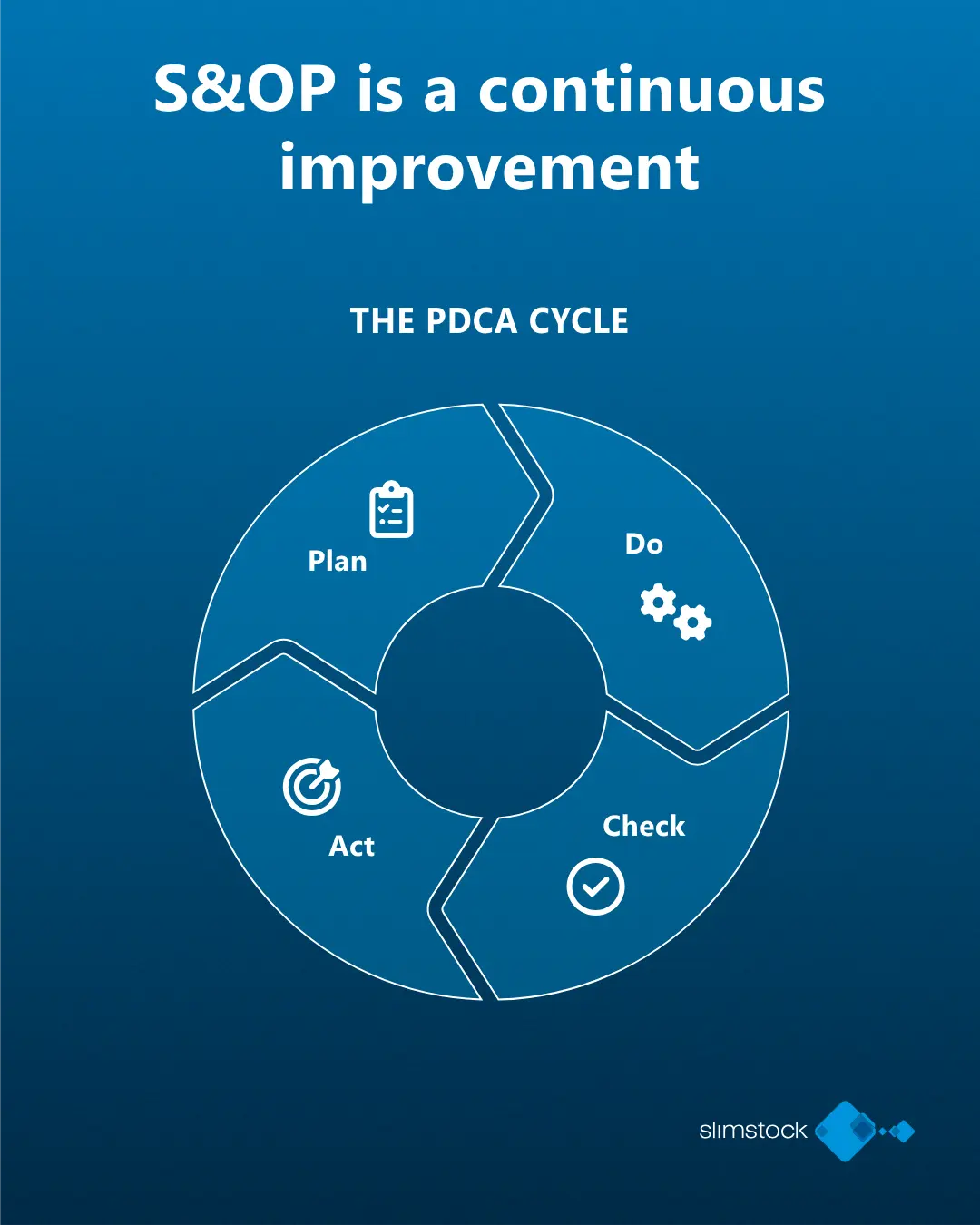

The S&OP process is a monthly and well-structured process. This has two major advantages; the teams have a clear and structured work process and with each monthly cycle the process is refined and improved. In order to win, you need to be prepared, so practice, practice and practice.

The 6 steps for the implementation of an S&OP process

These are the steps in the process that are executed on a monthly basis:

Data collection

Collect and consolidate relevant data, including historical sales data, market trends and production capacities.

Product Management Review

Evaluate and align Product Catalogue, new launches and life cycles with demand forecasts and production/supply capacities.

Demand review

Analyse customer behaviour patterns, market trends and sales forecasts at an aggregate level to optimise resources and inventory levels.

Inventory and Procurement Review

Review of inventory levels, supplier performance and capabilities to ensure an efficient supply chain.

Financial Review

Evaluate financial performance such as revenue, costs and margin to ensure that financial targets are aligned with the S&OP plan.

Pre-S&OP meeting

Meeting prior to the executive meeting in order to review and align inputs, previous assumptions and evaluate possible scenarios for the next S&OP cycle.

Executive meeting

Meeting at the highest level to review the entire plan, address strategic issues, make decisions to align operational objectives and strategic objectives.

The S&OP concepts

If you have come this far, and you think that S&OP is a good business approach, it is essential that you consider the following concepts. Once you have mastered them, they will allow you to exploit the full potential of S&OP.

- Planning is Aggregate and in Volume, not so much by Planning Mix or SKU.

- It is a cross-functional collaborative approach.

- Different units of measurement UOM’s, to allow the inclusion of the different realities and perspectives of the different functions of the company.

- It is a monthly or quarterly cycle where plans are reviewed and adjusted to detected and/or expected changes.

- It is a structured decision-making process.

Challenges during S&OP implementation

Implementing S&OP planning is not without its challenges. While most are surmountable, it is true that they require tenacity and knowledge. Successful S&OP is good communication and the key to good communication is the reiteration of our messages, through different channels and at different times.

- The main challenge is to engage, educate and train the teams not only in the process but also in the new direction.

- Align internal and external teams to achieve a single demand plan. Emphasise the need for effective and clear communication

- You will need to convince and inspire.

- Achieve focus and concentrate on what is important. Select those pains that have a clear return and are a quick win. This would allow you to start rolling and move forward.

- Make sure you have the right resources, both people and technology.

- Start small and build a solid foundation.

Benefits of S&OP planning

The challenges you will encounter in an S&OP process are outweighed by the great benefits. Here are some good examples:

- S&OP brings focus and sets direction, so that teams can move towards a common goal.

- Integrates and aligns the company’s long-term objectives with short-term objectives.

- Reduces inventory levels while reducing the risk of obsolescence by improving the use of working capital.

- Improve the level of service and delivery times to the customer.

- Increased visibility over the entire supply chain.

- It improves collaboration and communication and thus team safety and motivation.

Conclusions on sales and operations planning

Having the right information at the right time, when our environment is changing so rapidly, is vital.

Our plans may be very good and perfectly executed, but they are not isolated from reality and reality changes very fast.

Working at two levels, one very granular at the SKU level and the other at the aggregate level, allows us to adjust our plans to the changes detected in a quick and agile manner.

While working at SKU level requires detailed calculations and fine-tuning the different components of the multiple SKU forecasts, working at the aggregate or S&OP level allows working with a focus on assumptions, opportunities, scenario planning and risks. The latter, S&OP level, is by far more agile, although it does require greater alignment between the company’s decision-makers and the use of the appropriate technology.

The S&OP journey can be difficult. Seek help when you need it. Ask experts outside the company or within the company. Integrating different perspectives on possible solutions to the problem will allow you to advance solutions that are creative, pragmatic, easy or simply not considered as an option.

Optimise the S&OP process with Slim4!

Building consensus and a single source of truth has never been easier. If your S&OP process is struggling to deliver results, Slimstock’s Slim4 S&OP software can help you get it back on track by providing a collaborative, data-driven platform designed to enhance planning accuracy, visibility, and decision-making.

FAQS about Sales & Operations Planning

What is S&OP (Sales and Operations Planning)?

S&OP (Sales and Operations Planning) is an integrated business planning process aimed at balancing supply and demand. It is used to align sales and operations plans within an organisation. S&OP enables strategic and tactical decision-making through comprehensive planning that considers demand, production, capacity, and financial resources. This process ensures the organisation can meet market needs profitably and efficiently

What is the meaning of S&OP?

S&OP stands for Sales and Operations Planning. It is an integrated business planning process aimed at balancing supply and demand. S&OP helps align sales and operations plans, enabling strategic and tactical decision-making based on comprehensive planning.