Overview

Monthly forecasting is generally more accurate for most products due to its ability to absorb order timing variations, reduce data sparsity (zero entries) and better handle predictable seasonality. Weekly forecasting suits specific items with short lead times, consistent sales, or repetitive intra-month demand patterns.

Choosing the right forecasting method can make a significant difference to your accuracy, efficiency and bottom line. While weekly forecasting might seem more precise at first glance, thanks to its higher number of data points, it often leads to more noise than insight.

In this post, we explore why monthly forecasting tends to deliver more reliable results for the majority of products. From absorbing order timing variations to reducing data distortion and better handling seasonality, monthly forecasting offers key advantages that can improve your inventory performance and forecasting accuracy.

What is inventory forecasting?

Inventory forecasting is the process of estimating future demand to ensure that stock levels align with customer needs. It’s essential for retailers, wholesalers and e-commerce businesses, who often face challenges such as overstocking, understocking, and poor inventory control.

Accurate forecasting helps businesses maintain the right amount of stock, avoiding excess inventory costs while ensuring products are available when needed. Weekly and monthly forecasts are commonly used to anticipate short- and medium-term demand.

Which forecasting method is best for your business?

The goal of Slim4 – Slimstock’s inventory optimisation software – is to anticipate the future demand. Specifically, it helps determine how much of each item you’ll need to meet customer demand. Predicting the future is no easy work, even using historical data. With our ever more interconnected world, the volume of data points available is almost limitless, so the real challenge lies in identifying the right data and using it in a way that increases predictive accuracy.

When preparing to order inventory, two common approaches are typically used: monthly forecasting and weekly forecasting. But which method works best? It’s easy to assume weekly forecasting is superior, as more frequent data points might appear to offer greater accuracy. If 12 data points are good, then 52 must be better, right? This isn’t always the case. To improve this, many companies turn to demand forecasting software that integrates advanced analytics for more accurate predictions.

With over 30 years of experience helping customers get the right product to the right place at the right time, we’ve seen that most products can be predicted and ordered more accurately using monthly forecasting.

Monthly Forecasting

Put simply, monthly forecasting means that sales data is captured daily and bucketed into months to produce a forecast. Similarly, weekly forecasting involves bucketing daily sales into weeks to create a forecast. This creates 40 more forecast periods over the course of a year.

Monthly forecasts work best for most products because they tend to generate lower forecast errors. While there is variation in how many units are sold week to week within a monthly forecast, if we’re doing our job correctly, you’ll still have the right amount on your shelves whether it’s 1st, the 15th or the 30th of the month.

Advantages of a monthly forecasting approach

There are three main reasons why monthly forecasting tends to be more reliable than weekly forecasting:

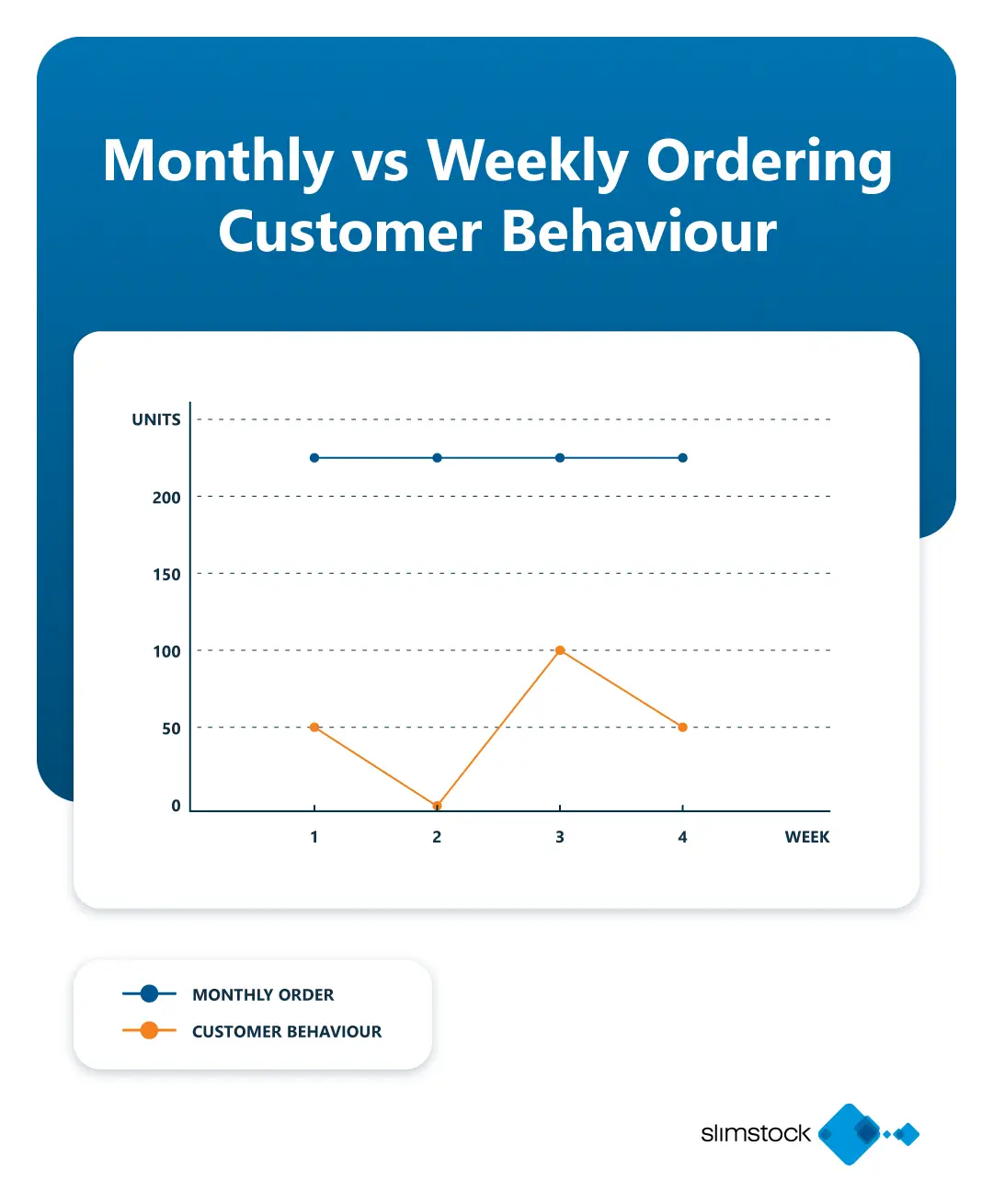

Better absorption of order timing variability

Monthly forecasting uses broader time buckets, which makes it more resilient to shifts in customer ordering patterns. For instance, if a customer who normally orders a part from you in the first week of a month instead orders it in the second, this can disrupt your order data. However, this potential disruption is nearly four times as likely to be absorbed by monthly forecasting, leaving your order data unaffected.

Fewer zero entries improve accuracy

Monthly ordering reduces the number of zero entries in your data, meaning the law of averages works for you. For example, if a customer places an order with you for 100 units every two weeks, it results in a simple average of 50 units per week. But, the forecast error relative to this average will always be wrong because the order quantity is never 50, it’s either 100 or 0. Taking a monthly view of this order pattern makes correct forecasting easier because it shows consistent usage with fewer zero entries.

Improves handling of seasonality

Monthly timeframes handle seasonality better. Months are predictable, they’re in the same order every year. Weeks, on the other hand can shift by up to four days year-on-year. The relative unpredictability of weeks makes them more difficult to use when factoring in seasonality, especially if there are only a few years of data to base forecasts on. Monthly timeframes more reliably allow general tendencies to develop and be represented in your order data.

Weekly Forecasting

Even an accurate forecast amount isn’t much good to you if it doesn’t show anticipated demand over the right period of time. If this happens, you’ll have stockouts and falling customer service goals will be soon to follow.

As stated earlier, while weekly forecasting requires more effort than monthly, it can be appropriate for items that have an observable repetitive pattern of usage within each month.

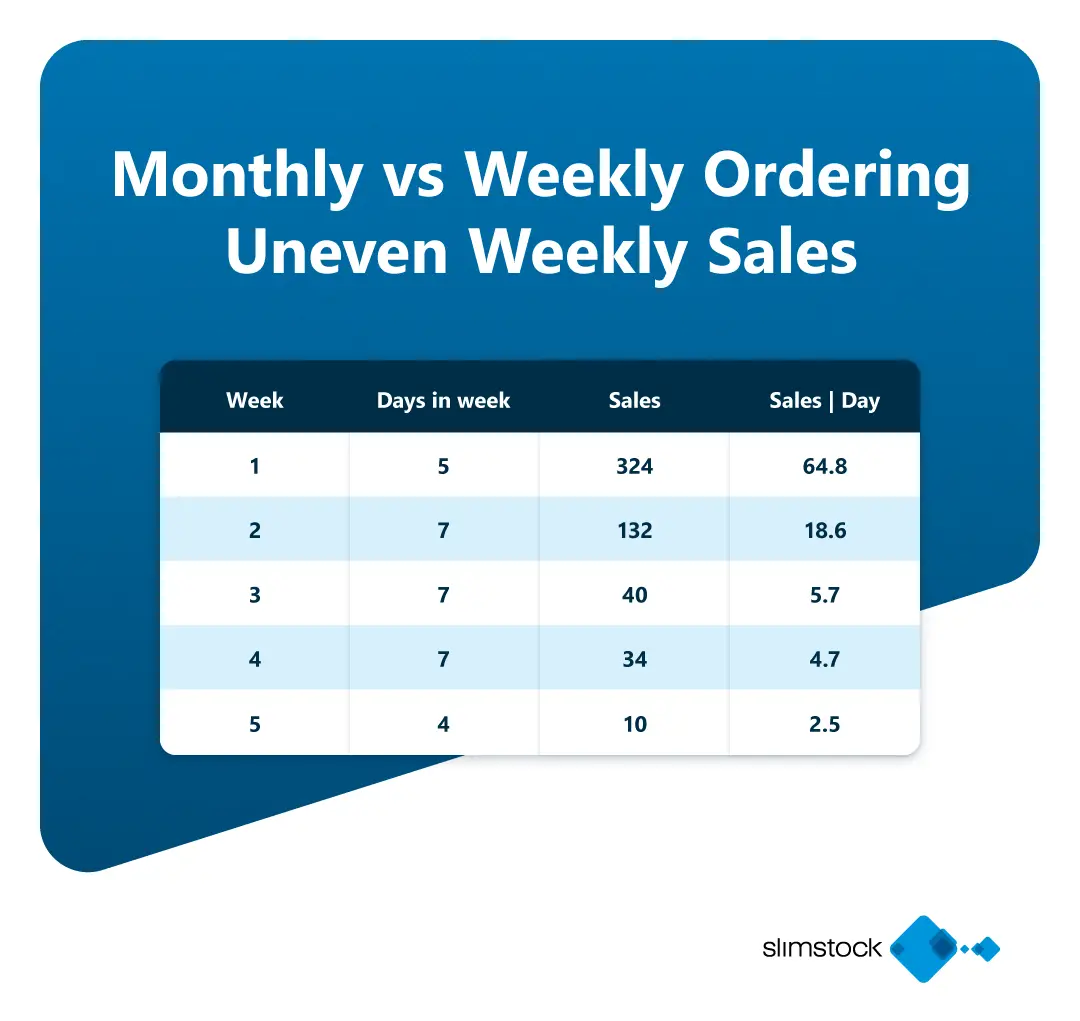

Here is an example of an item that meets this criteria.

With 60% of sales coming in the first week of the month, this product is good candidate for weekly forecasting.

Items with short lead times and consistent sales work best for weekly forecasting. By identifying these opportunities, the product can be ordered close to when it is needed, which helps improve inventory revenue and the overall profitability of the company.

Benefits of weekly forecasting

Other advantages to weekly forecasts are:

Compatibility

If your customer is communicating with you in terms of weekly forecasts or weekly Point-of-Sale (POS) information, generating your own forecasts in kind can provide an invaluable direct linkage with them. Getting that direct linkage with data closer to the retail customer may outweigh any potential internal forecast accuracy improvements.

Medium volume items

If you are dealing with medium volume items, a weekly approach produces more accurate trend lines and better reflects shifts in demand.

Slimstock’s implementation team will help you identify which type of forecasting is best for your product array based on historical sales data. For items that fit weekly forecasting criteria, Slim4 distributes volumes from monthly forecast data to the appropriate week in the month using historical pattern references or defined business rules. This approach delivers the advantages gained from monthly forecasting as outlined above, while accounting for observable specialized demand needs within the month.

Monthly or weekly forecasting, the best way to decide which approach is right for you is to schedule a demo of Slim4 with our inventory experts. They will run your ordering data through our proven inventory optimization software to show you real savings opportunities that have delivered post-implementation ROI of 6-12 months for most customers.