Table of contents

Table of contents- Logistics Network Design: Strategies for Efficient Inventory Planning

- What is a logistics network?

- Key components of logistics networks

- Strategies for logistics network design

- Impact of an efficient distribution network

- Continuous planning is the key to success

- Logistics Network FAQs

Overview

Logistics network design, comprising facilities, transport, processes like factories, warehouses and distribution centers is crucial for supply chain efficiency. Key strategies for optimization include optimal network configuration, careful inventory planning to balance stock and costs, potential logistics outsourcing and leveraging advanced technologies such as WMS and automation. A well-designed network ultimately reduces costs, improves service, increases flexibility and enhances sustainability.

In a business environment marked by uncertainty, supply chain efficiency is more important than ever. A key factor in achieving this efficiency is the design and optimisation of distribution networks. These networks allow companies to manage the flow of products from both factories and from suppliers to the end consumer. Having the correct logistics network design in place can make the difference between an efficient operation and one that incurs excessive storage and/or distribution costs.

In this article, we will explore how companies can optimise their distribution networks, focusing on the aspects that have the greatest impact on inventory management. From warehouse configuration to the use of advanced technologies, we will look at how a well-designed network can make a significant contribution to improving a company’s financial and operational performance.

What is a logistics network?

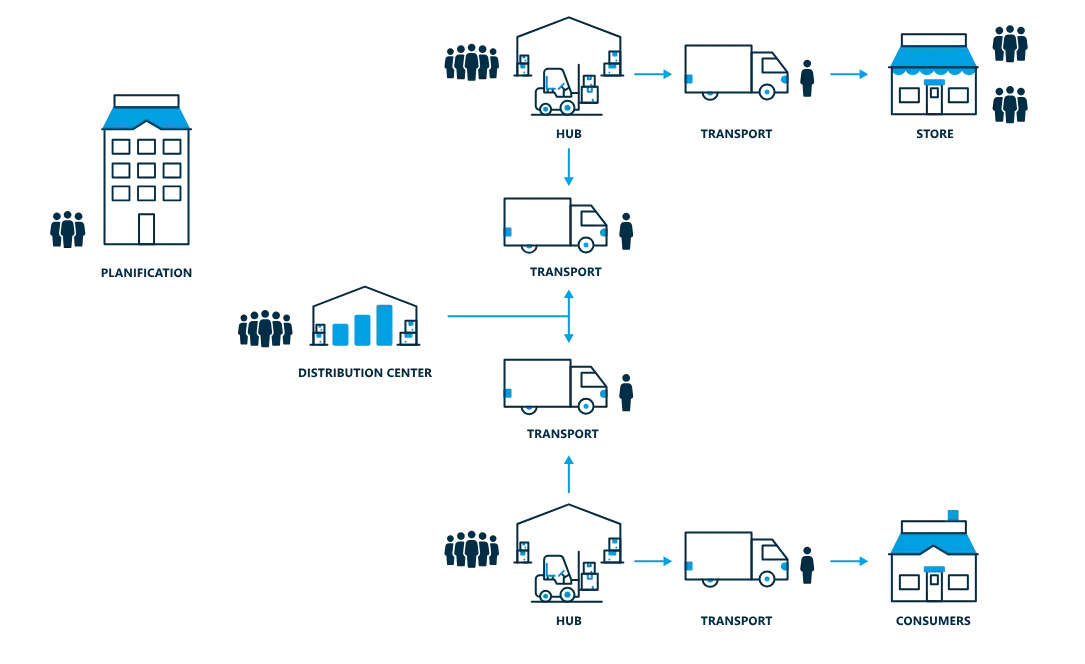

A logistics network is the set of facilities, means of transport and processes that allow products to flow from the supplier to the final consumer. This network includes factories, distribution centres, warehouses and shops, all interconnected by logistics routes. In addition, the network also manages critical aspects such as transport, handling and storage of products.

The efficient and smooth design of a logistics network is paramount when it comes to minimising costs and maximising product availability. Poor planning can lead to increased warehousing costs and excess inventory or stock-outs that directly affect customer satisfaction.

Key components of logistics networks

1. Warehouses

Warehouses are at the heart of any logistics network. Their main function is to coordinate imbalances between supply and demand. The key role of a warehouse is as follows:

- Product storage: Products are stored until they are required for distribution.

- Consolidation of goods: Goods from different suppliers can be consolidated, enabling them to be distributed more efficiently to outlets or customers.

- Cross-docking: In some operations, products arriving at warehouses are quickly distributed without being stocked, which reduces inventory costs and times.

According to the main functions they perform, we can distinguish between different types of warehouses:

- Consolidation warehouses: Goods are grouped from different suppliers and distributed to various points of demand.

- Dispatch centres: Products are received from suppliers and sent directly to customers, omitting the need for warehousing.

- Plant supply centres: Raw materials are stored ready for use in production, directly supplying plant according to the needs of the production process.

2. Factories

Factories are the point of origin of most products. When planning logistics networks, it is important to consider how products are managed in the factory. There are several production models, each with different logistics implications:

- Make to Order (MTO): Products are manufactured after the customer’s order is received. Although this reduces inventory costs, it can lengthen delivery times.

- Make to Stock (MTS): Large volumes of standard products are produced for warehousing, allowing faster delivery, but increasing inventory costs.

3. Distribution centres

Distribution centres (DC) are facilities where inventory is stored before being shipped to retail outlets or end customers. The DC’s location is critical to optimise delivery times and reduce transportation costs. An effective distribution network design may involve having one or more distribution centres, depending on geography and demand.

4. Sales outlets

Retail outlets can be physical or digital. In physical shops, it is essential to have an adequate level of inventory to avoid stock-outs, but without incurring excessive costs. In e-commerce, speed of delivery has become a key competitive differentiator, requiring precise planning of distribution from logistics centres or from shops to the end customer.

5. Transport

Transport plays a critical role in every distribution network. Optimising routes and selecting the most appropriate modes of transport (truck, plane, rail, and ship) is essential to reduce costs and ensure fast delivery. In some cases, companies may choose to outsource these services to logistics operators.

Strategies for logistics network design

1. Optimal network configuration

The first step in optimising a distribution network is to design it correctly. This involves selecting the geographical location of the warehouse, plant and distribution centres, allocating products to the various facilities and mapping out the most efficient logistics routes. This process must take into account both current demand and future growth forecasts.

Key decisions in the configuration of the logistics network

- Number and location of warehouses: The more warehouses a company has, the more responsive it will be, but inventory costs will also increase.

- Size of warehouses: Size must be adapted to the demands of the network, ensuring that there is sufficient storage capacity without incurring unnecessary costs.

- Functions of warehouses: As we have seen above, some warehouses act as consolidation centres, while others are designed to process orders quickly through cross-docking. The chosen function of each warehouse depends on the company’s strategy.

2. Inventory planning

One of the main objectives of a distribution network is to find the optimal balance between having sufficient inventory to meet demand and minimising the costs associated with warehousing and stock management. To do this, it is essential to accurately calculate safety stock levels. This is the extra amount of inventory held to cover unforeseen demand or supply chain problems.

Strategies to reduce inventory costs:

- Centralisation of inventories: Consolidating inventories into just one or a few large warehouses can reduce storage costs and levels of safety stocks.

- Inventory management technologies: Warehouse management systems (WMS) allow real-time inventory monitoring and positioning of product in the warehouse to minimise picking and preparation time. The use of good Demand Forecasting: is crucial to avoid both overstocking and stock-outs.

3. Outsourcing of logistics

Sometimes the outsourcing of part of the logistics operation to a specialised operator can be cost-effective. Logistics operators can offer economies of scale, allowing companies to minimise costs and improve service levels. However, it is important to carefully assess the implications of outsourcing these key functions, as there may be a loss of control over some aspects of the operation.

4. Use of advanced technologies

The use of advanced technologies is essential to optimise distribution networks. Today, companies can rely on a wide range of tools that improve operational efficiency and decision-making accuracy:

- Warehouse Management Systems (WMS): These systems allow real-time inventory control, optimisation of storage and despatch processes, and improved accuracy in order picking.

- RFID and barcodes: Both facilitate the identification and tracking of products within the warehouse.

- Pick-to-light and Pick-to-voice: These are systems that guide operators in the preparation of orders, improving the accuracy and speed of picking.

- Automation: Automated guided vehicles (AGVs) and robotic systems for product handling help reduce operating times and increase efficiency.

5. Designing logistics networks for e-commerce

The rise of e-commerce has changed customer expectations in terms of delivery times and flexibility in shipping options. To meet these new demands, many companies are adopting concepts such as urban hubs and dark stores:

- Urban hubs: These are small, multi-company warehouses located in metropolitan areas that enable fast last-mile deliveries, reducing transport costs.

- Dark stores: These are shops closed to the public that serve exclusively as preparation centres for e-commerce orders. They are served by riders or fast delivery cyclists, speeding up delivery times.

Impact of an efficient distribution network

Optimising a distribution network has a direct impact on a company’s operational efficiency and profitability. Here are some of the main benefits that can be achieved:

1. Cost reduction

The optimal design of the distribution network reduces transport and warehousing costs. By minimising distances between distribution centres and retail outlets or end customers, companies can reduce shipping costs. In addition, inventory consolidation can reduce the costs associated with warehousing and handling of products.

2. Improved level of service

A well-designed network ensures that products are available when and where customers need them. This not only improves customer satisfaction, but also helps companies compete in increasingly demanding markets.

3. Increased flexibility

An optimised distribution network also provides greater flexibility to adapt to changes in demand. This is especially important in volatile markets, where fluctuations in demand can affect product availability.

4. Sustainability

By reducing unnecessary journeys and optimising logistics routes, companies can also reduce the environmental impact of their Supply Chain. Sustainability is increasingly important to both consumers and businesses, so optimising the distribution network can have a positive impact on a company’s carbon footprint and therefore its reputation.

Continuous planning is the key to success

We have looked at how to realise the benefits of distribution network design and optimisation. Investing in an efficient distribution network not only reduces costs and improves service, but also provides a long-term competitive advantage.

Most importantly, this is not a process to do once and forget about, it is not a static process; it requires continuous planning to adapt to changes in demand, technologies and market conditions.

Companies that take a strategic approach to the design of their logistics networks and take advantage of advanced technologies can significantly improve their operational efficiency, offering a better service to their customers while reducing operational costs and environmental impact. The correct stock is in the right place at the right time by optimising inventory distribution between warehouses and distribution centers with the use of specialized tools like Slimstock’s network balancing software.

Logistics Network FAQs

What is a logistics network?

A logistics network is the system of facilities, transportation, and processes that allow products to flow from suppliers to final consumers. It includes factories, warehouses, distribution centers, and shops, all connected by transport routes.

Why is logistics network design important for supply chain efficiency?

Proper design of a logistics network minimizes costs, improves product availability, and ensures efficient management of storage, transport, and distribution. A well-designed network reduces excess inventory and shipping costs, while poor planning can lead to stock-outs or costly warehousing.

What is the difference between a “distribution centre” and a “warehouse”?

Although the two terms are often used interchangeably, there is a key difference: a warehouse is usually focused on long-term storage of products, while a distribution centre is designed for a faster flow of products, with the aim of distributing them to shops or customers in the shortest possible time. In addition, distribution centres often perform other tasks such as product consolidation or order picking.

What is “cross-docking” and how does it benefit the distribution network?

Cross-docking is a logistics technique in which products arriving at a warehouse or distribution centre are not stored, but transferred directly to delivery vehicles for distribution. This method significantly reduces warehousing times and associated costs, as products spend less time in inventory. It also allows for a faster response to demand and improves efficiency in the delivery of goods.

What is a Warehouse Management System (WMS) and what benefits does it offer?

A warehouse management system (WMS) is software that controls and optimises operations within a warehouse. Its functionalities include managing inventory, monitoring the flow of goods, allocating storage space and optimising picking and packing. A WMS improves operational efficiency, reduces errors in inventory management and increases accuracy in order picking, which translates into better customer service and lower operating costs.

How do “economies of scale” affect the distribution network?

Economies of scale occur when a company reduces unit costs by increasing the volume of production or distribution. In a distribution network, this may mean consolidating inventories in fewer large warehouses or using logistics resources, such as transportation and warehousing, more efficiently. By managing larger volumes of products centrally, companies can reduce unit costs, which improves operational profitability.