Table of contents

Table of contents- Inventory Management: Attaining a 360° perspective with S&OP

- Different perspectives of inventory management success

- Sales

- Finance

- Operations

- Procurement

- Managing Conflict with S&OP

- Joining the dots with Sales & Operations Planning

- How can S&OP enable better inventory management?

- Final thoughts on S&OP

- Inventory management FAQs

Question: What is the worst-kept secret in any business?

The answer is that different departments have different goals. And as anyone in the Supply Chain Team knows, these goals often conflict.

Who hasn’t seen someone in the Sales Team rue the lack of inventory in the warehouse? Or someone in Finance refusing a purchase order for, in their opinion, a poor use of working capital? Or the Purchasing Department refusing Finance’s refusal, due to the large contract the business signed last week that no one knows about yet …?

It’s one of the great complexities in business. How can we be even remotely profitable if everyone is running around in different directions? Inventory is at the core of many companies, and these different perspectives often lead to suboptimal decision making.

The issue is that the departments in your business need different goals. In order to achieve great results, the aims of members of the Finance Team are naturally going to differ from those working in Purchasing, or frankly, any other department.

Sales want sales … at any cost. Marketing wants a bigger budget. Your Warehouse Team wants more space. And Ops just want to do less fire-fighting.

But each team in your business needs to be better at sharing their differing expectations and aligning their strategies on how to achieve them … for everybody’s benefit, including that of the overarching business.

Only then can you work towards better supply chain planning.

In today’s blog, we explore how you can use S&OP as a platform to unify everyone across the business to make better decisions.

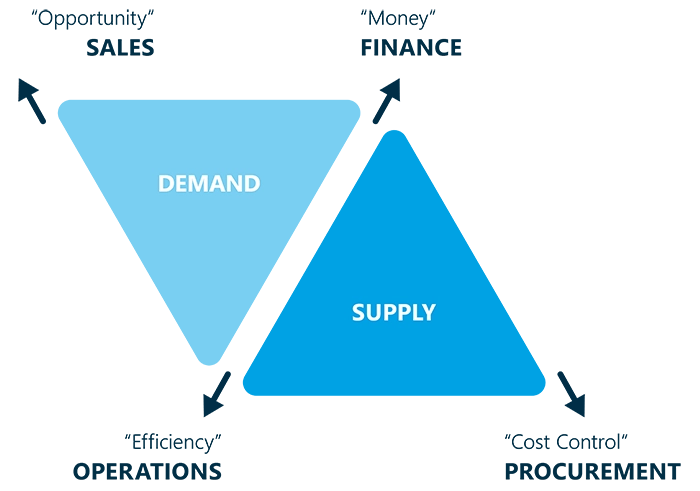

Different perspectives of inventory management success

Supply chain success means different things to different people. That includes the varying departments of your business.

And this leads to siloed planning, poor communication and negative results. It also probably angers your Chief Supply Chain Officer at 3am, as they scribble in their notepad to ease their insomnia.

Let’s explore some different perspectives.

Sales

For Sales, inventory means ‘opportunity’.

That’s the key word for Sales, when they think of inventory.

If you don’t have it in stock, you won’t meet your customer’s expectations. You might lose sales, or brand recognition, or just make it harder to make sales further down the line.

Your Sales Department is often driven by commercial incentives, and not by meeting margin targets.

This can lead to unrealistic expectations of what your inventory should be. Or worse still, buying inventory in anticipation of a big order that may never materialise.

As any piece of inventory is an opportunity, sales will regularly ask for more, without a reasonable plan on how to turn it into profit.

Finance

For Finance, inventory means ‘money’.

Inventory is an asset with a high associated risk.

And while inventory is more liquid than other assets, like real estate, it’s less liquid than hard cash.

And even then, some inventory might be obsolete and can’t be turned into cash without significant efforts.

From a Finance perspective this can lead to inventory being seen as a cost you must manage.

Finance understands more than most the value of inventory. If you manage to have an average of 1 unit in stock, and make 12 sales a year, that’s more profitable than having 4 units in stock to make 12 sales.

On the other hand, Finance is relatively unbothered by depreciation, and more considerate of cash flow issues.

You might find them asking to reduce working capital investments, with the issue being that it’s easier to achieve working capital reductions on inventory that moves … which ironically is the inventory you want.

An important consideration when dealing with cash flow issues is to see where you can cut back.

Operations

Inventory to Operations means ‘efficiency’.

People in Logistics, Warehousing and Transportation are born to optimise.

Why would you bother opening a package, when it’s much easier to ship a full pallet?

For Operations, efficiency is a core belief, and it’s sometimes difficult for them to see why some inefficiencies are necessary, or to even notice that their efficiency actually costs money in the long run, because that full truckload might be sitting in inventory for months.

Procurement

Inventory to Procurement equates to ‘acquisition costs per unit’.

“Can we make a detour to grab butter at that grocery store 10 minutes away? They’re running quite the promotion.”

This is how Procurement Teams are often viewed by other departments. They find the best deal and are killer negotiators.

It’s their natural talent to squeeze everything out of a vendor. But the impact on supply chains? That’s harder to quantify.

Large minimum order quantities can increase the total cost of ownership (TCO) of an item tremendously. Long lead times increase the need for more inventory.

You need to fill up a container? We might be looking at anywhere between 1-6 months worth of inventory.

Procurement Teams are often incentivised by spend considerations. The less they spend per unit, the better. Discounts can lead in the negotiation of new contracts.

Managing Conflict with S&OP

These different perspectives can lead to conflict in your business … and no doubt already have … conflicts which impact your bottom line, and become a leading cause of frustration and burnout.

Therefore, your business needs to align better, not only on your goals and expectations, but also on the direction you go when issues arise.

Your teams must be aware of the constraints in which your business is allowed to operate.

So how can you achieve this?

Joining the dots with Sales & Operations Planning

Sales & Operations Planning (or S&OP) is a well-established process where departments meet monthly to discuss both the alignment of sales and demand, and the operational fulfilment of that demand.

Some compare the S&OP process to that of an orchestra.

It might be comprised of many talented individuals who work well on their own, but a far more beautiful outcome is achieved when there’s harmony.

S&OP is the process of harmonisation, or synchronisation.

It’s not the intention of this blog to discuss the S&OP process in much detail, but I would like to emphasise that it’s the most likely setting for you to resolve conflicts between your departments.

Anyone involved in supply chain planning should realise the importance of holding inventory for customers for when they want it, and the need to collaborate with Sales in order to achieve that.

Any planner should know when a cash crunch is likely to take place. Together with Sales, Finance can mitigate a cash shortage by getting rid of unwanted products instead of just moving them, so that future sales aren’t compromised.

Procurement might design contracts around total cost of ownership.

Many vendors are probably willing to cooperate with your demands to have items sold at lower quantities and higher prices … or higher quantities and lower prices.

With Operations, you’ll probably have to agree that your economic order quantities can easily be rounded to units that make sense. Maybe it’s the case that shipping three coffee cups is only slightly cheaper than shipping a full pack.

Optimising to the last decimal point often has adverse effects. And given that most parameters you work with are never 100% exact, the difference can be negligible.

How can S&OP enable better inventory management?

Sales and Operations Planning (S&OP) is a crucial part of the inventory management process. It plays a pivotal role in enhancing collaboration between different teams within your company.

Cross-Functional Alignment:

S&OP brings together key stakeholders from various departments, including Sales, Operations, Finance, Marketing and Supply Chain.

By involving representatives from these diverse teams, S&OP ensures that everyone is aligned with the company’s inventory management goals and objectives.

Data Sharing and Transparency:

S&OP relies on accurate and real-time data from different departments. This enables teams to share information transparently and to maintain a single source of truth. When teams have access to the same data, it fosters trust and encourages collaborative decision making.

Demand and Supply Integration:

S&OP enables teams to synchronise their efforts by aligning demand forecasts with supply chain capabilities.

Sales and Marketing teams provide valuable insights into market demand, while Operations and Supply Chain Teams provide data on production and distribution capacity. Collaboratively, they work to balance supply and demand, and so reduce the risk of stockouts or overstock situations.

Scenario Planning:

S&OP allows teams to compare various scenarios to address different market conditions and uncertainties.

By collaborating on these “what-if” scenarios, your teams can anticipate potential issues and develop strategies to mitigate risks. This collaborative approach enhances agility and preparedness.

Consensus Decision Making:

S&OP meetings often involve discussions, negotiations and consensus-building among your teams. Decisions are made collectively, taking into account the input and concerns of each team.

This collaborative decision-making process ensures your inventory management strategy is well balanced and acceptable to all stakeholders.

Continuous Improvement:

S&OP is not a one-off event, but an ongoing process.

Your teams must meet regularly to review and refine your plan. It’s a continuous improvement cycle, which encourages your teams to collaborate on finding better ways to optimise inventory levels, reduce costs, and meet customer demands efficiently.

Communication and Accountability:

S&OP establishes clear communication channels between teams. Each team is responsible for specific actions and outcomes, and their responsibilities are clearly defined in the S&OP process.

This accountability ensures that teams are motivated to collaborate effectively to meet their objectives.

Customer-Centric Approach:

Collaboration through S&OP is centred around meeting your customers’ needs. By aligning all teams with a customer-centric focus, you can ensure your inventory management decisions prioritise customer satisfaction, which is essential in today’s competitive markets.

Performance Metrics and KPIs:

S&OP often includes key performance indicators (KPIs) that are tracked and monitored collaboratively. Your teams can see the impact of their actions on inventory turnover, service levels, and other relevant metrics, which encourages continuous collaboration to achieve better results.

Before you rip up the entire company strategy, however, I’m not suggesting you align every single KPI in your business.

Different departments mean different people, and therefore different incentives to succeed.

It is the magic mix that makes companies successful. You must however work to achieve reasonable alignment, and S&OP is a great process that enables you to achieve this.

Final thoughts on S&OP

S&OP is one of the best solutions in modern commerce for aligning the often differing desires of your various departments.

While it’s by no means a silver bullet for effective inventory strategy, it’s an incredibly successful method of keeping your business on track and offering your customers a meaningful way of meeting their demands.

It means Sales will have an appreciation of Finance’s restrictions. And Finance understands why Sales act in the way they do. It will help your Purchasing Team see the Marketing Department’s viewpoint. And it may well help your Chief Supply Chain Officer sleep more soundly at night.

But above all else, it brings your business together under one strategic roof, working in collaboration towards a single goal. It’s a 360° proposal, to ensure your company is aware of the bigger picture as you navigate increasingly in difficult markets.

For more information on any of the topics discussed in today’s article, get in touch with a Slimstock expert.

Inventory management FAQs

Why is S&OP considered crucial for inventory management?

S&OP is crucial for inventory management because it facilitates cross-functional alignment, enabling seamless collaboration between departments including Sales, Operations, Finance, Marketing, and Supply Chain. Ultimately, S&OP can facilitate better decision-making, improved transparency, and ultimately, more effective inventory management.

How does S&OP address conflicts between different departments in a business?

S&OP addresses conflicts between different departments in a business by providing a robust platform for regular meetings, discussions, and consensus-building, fostering understanding and alignment of goals among Sales, Operations, Finance, Marketing, and Supply Chain teams.

What are the key benefits of implementing S&OP in inventory management?

Implementing S&OP offers key inventory management benefits such as cross-functional alignment, transparent data sharing, demand and supply integration, continuous improvement, and performance metric monitoring. As a result, businesses become better positioned to optimise inventory levels while support overall business objectives.

How does S&OP promote a customer-centric approach in inventory management?

S&OP promotes a customer-centric approach in inventory management by aligning diverse teams, such as Sales, Operations, Finance, Marketing, and Supply Chain, to prioritise customer needs, ensuring decisions enhance customer satisfaction and responsiveness in competitive markets

What are some inventory management performance metrics and KPIs associated with S&OP?

Inventory management performance metrics and KPIs associated with S&OP include inventory turnover, service levels, and other relevant indicators that are collaboratively tracked to ensure continuous improvement and better results across the entire business.