Table of contents

Table of contents- Inventory planning guide: what it is, techniques, processes, examples & solutions

- What is inventory planning?

- Differences between inventory planning, demand planning and assortment planning

- Key benefits of optimised inventory planning

- Steps to improve inventory planning

- Inventory planning methods and techniques

- Inventory management’s star player

- Better decisions, happier customers, stronger profits

Overview

Inventory planning is a key supply chain activity that ensures the right inventory levels are maintained to meet demand while minimising costs. By using demand forecasts, data analysis and supplier coordination, it helps businesses avoid stockouts, reduce excess inventory and improve cash flow, ultimately supporting a more efficient and resilient supply chain.

Balancing supply and demand is seen as the ultimate goal of supply chain optimisation. If you can match the two, then you’re surely being as efficient, cost-effective, customer-pleasing and profit-maximising as you could possibly be, right?

Not necessarily. There is a huge function between the two that both feeds off those supply-demand metrics, but that also needs optimising in its own right if those ultimate benefits are to be realised.

That function being, inventory planning.

What is inventory planning?

Inventory planning is the discipline of ensuring that a business carries the right level of stock to meet demand without generating unnecessary costs. At its core, it balances availability, efficiency and profitability. Rather than simply guessing order quantities or reacting to shortages, optimised inventory planning uses data, accurate forecasting, supplier insight and strategic analysis to determine the ideal amounts of each item to hold at every stage of the supply chain, in which location and for how long.

For retailers, wholesalers, manufacturers and ecommerce operators alike, optimal inventory planning keeps shelves full, warehouses lean, workers satisfied and customers fulfilled. It is both a strategic exercise (shaping budgets, margins, and assortment decisions) and an operational one, affecting replenishment cycles, warehouse productivity and day-to-day purchasing decisions.

Differences between inventory planning, demand planning and assortment planning

These three disciplines are often mentioned together, yet they serve distinct purposes within broader supply chain strategy.

- Demand planning answers: How much are we likely to sell?

- Assortment planning answers: What should we sell, and where?

- Inventory planning answers: How much stock should we hold to meet demand in the most efficient and profitable way possible?

In essence, demand planning informs the forecast, assortment planning shapes the range and inventory planning makes sure the business can supply that range without disruption or waste. When these processes are aligned, inventory flows become smoother, financial performance improves and customers enjoy a more consistent experience.

Key benefits of optimised inventory planning

When an organisation has a reliable planning framework in place, the results are felt across the entire business. Strong inventory planning reduces risk, strengthens financial performance and supports long-term growth.

One of the most immediate benefits when inventory planning is optimised, is improved product availability. Customers today expect consistency, regardless of season or channel. Meeting those expectations builds loyalty and protects revenue. If you can align stock capacity, handling and balancing across the network, then you’ll be able to meet demand without overstocking and without experiencing obsolescence of goods. Optimised inventory management doesn’t mean guaranteeing availability at any cost, it means guaranteeing it at the exact right cost according to accurately predicted demand.

Operationally, smoother inventory flows lead to better teamwork across purchasing, sales, operations and finance. Warehouses become easier to manage, supplier relationships improve and the business is better prepared to handle unexpected events such as supply disruptions or spikes in demand. Optimised planning also enhances strategic decision-making because it encourages organisations to analyse data rather than rely on intuition.

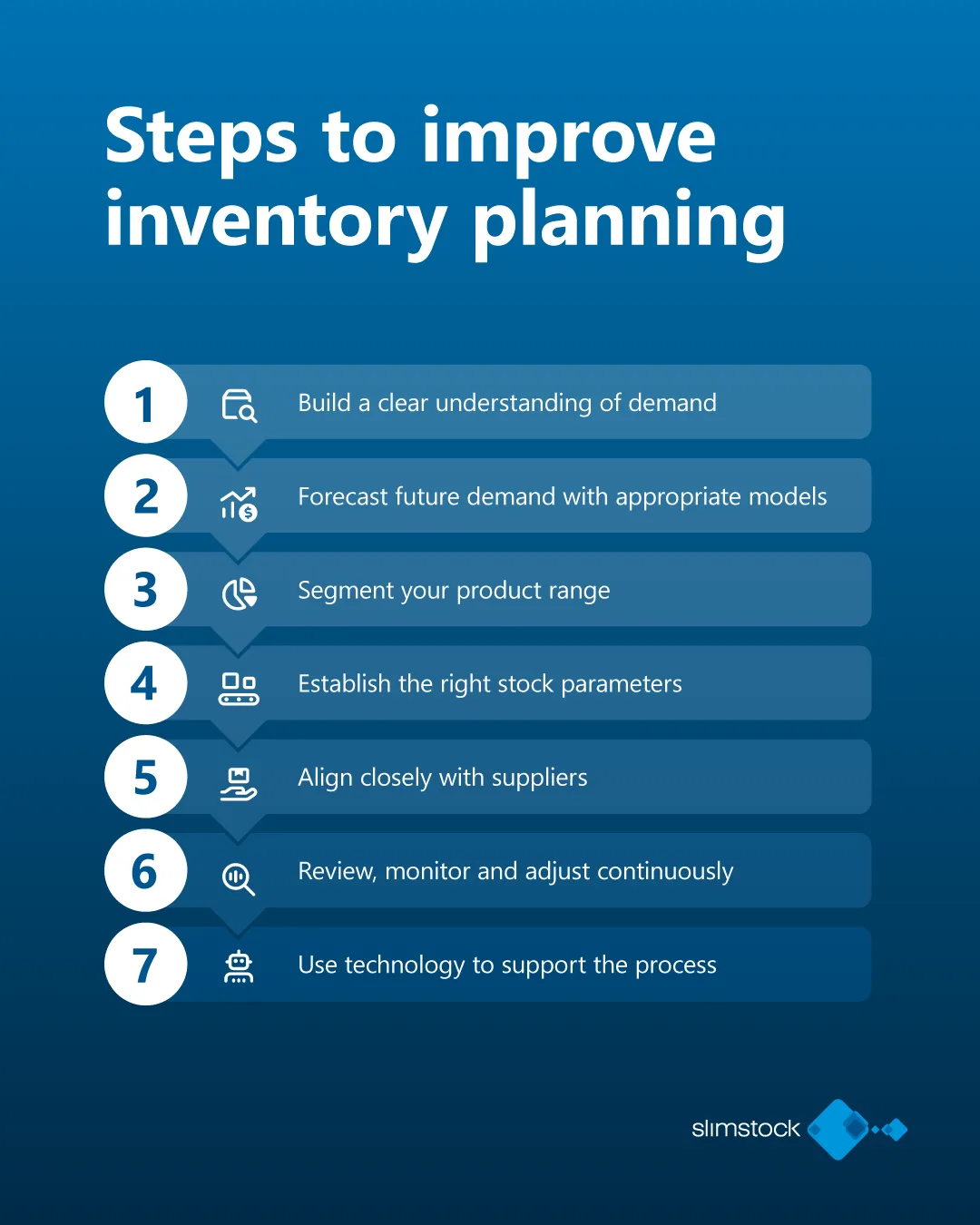

Steps to improve inventory planning

Improving inventory planning isn’t a one-off exercise. It’s an ongoing cycle of forecasting, monitoring, and refinement. Below is a more detailed walkthrough of your prospective inventory transformation.

1. Build a clear understanding of demand

The foundation of any planning strategy is demand clarity. Companies should be able to examine historic sales patterns, market drivers, seasonality and promotional activity. Qualitative input from sales teams, category managers, or market trends also helps to contextualise the numbers.

2. Forecast future demand with appropriate models

Depending on complexity, businesses may use simple moving averages, statistical models or advanced forecasting tools. The aim is not perfection but probabilistic accuracy that unlocks decisions according to what’s needed and what’s possible in real time.

3. Segment your product range

Not all products are the same, carry the same demand, have the same expiration lifecycles, can be distributed or moved in the same way. By grouping items based on sales velocity, margin contribution, their characteristics or strategic value, teams can focus resources where they matter most. Optimal prioritisation sees high-value or fast-moving items treated accordingly, therefore maximising sales opportunities and ultimate profit margins.

4. Establish the right stock parameters

Here, the business defines safety stock, reorder points and lead-time expectations. These calculations help ensure availability while minimising waste. The more stable and predictable the supply and demand, the leaner these parameters can be.

5. Align closely with suppliers

Reliable planning relies heavily on reliable suppliers. Clear communication around lead times, order quantities, shipment visibility and capacity helps to reduce surprises. Many companies also share demand forecasts with suppliers to strengthen this collaboration.

6. Review, monitor and adjust continuously

Performance indicators such as stock turns, fill rate, forecast accuracy, or aging stock offer valuable feedback. Regular reviews ensure that planning remains aligned with business objectives and market dynamics.

7. Use technology to support the process

Manual planning often leads to errors and inefficiencies. Modern planning tools streamline replenishment, aggregate data, automate calculations and provide early warnings about potential issues such as delayed purchase orders or unexpected spikes in demand.

Inventory planning methods and techniques

Optimised inventory planning requires effective balancing, prioritisation, scenario planning and management and agility. These necessities can be unlocked through your chosen supply chain platform, making it imperative that you select a solution that carries certain critical modules.

One such module is ABC/XYZ analysis, which categorises products by value or importance. This technique highlights which items require stricter controls and which can be managed more flexibly, while also looking to maximise the sales potential of high-value items.

It’s also important to weigh up decisions against your own capabilities and objectives. An Economic Order Quantity (EOQ) module helps determine the most cost-efficient quantity to order at any given time, balancing the trade-off between ordering costs and holding costs. Meanwhile, lean-oriented businesses may apply Just-in-Time (JIT) practices to minimise inventory altogether, receiving goods only when needed.

Finally, demand forecasting models, whether simple time-series methods or AI-driven algorithms, provide the predictive backbone that ensures planning is proactive rather than reactive.

Inventory management’s star player

Inventory planning sits at the centre of inventory management. Inventory management encompasses all activities related to controlling, storing, and moving stock, including warehousing, stock rotation, audits, purchasing and fulfilment. Inventory planning serves as the strategic epicentre of this ecosystem. It looks ahead, anticipating what stock will be needed, where and to what extent.

A well-run inventory management process relies on solid planning. Without accurate forecasts and well-calculated stock parameters, even the best warehouse system will struggle. Conversely, excellent planning provides little value if operational execution is weak. The two functions rely on each other.

Planning also plays an important role in financial management. It supports budgeting, helps prevent capital from being locked into excess inventory and provides visibility into future purchasing needs, all of which support stronger business stability.

Better decisions, happier customers, stronger profits

Inventory planning is a vital capability for any organisation that wants to operate efficiently, maintain healthy margins, and deliver outstanding service. It combines data analysis, forecasting, supplier collaboration, and strategic thinking to ensure that stock levels are always aligned with business goals and real-time demand.

By applying structured planning steps, adopting proven techniques, and integrating modern technology, businesses can build supply chains that are resilient, agile and financially sound. Whether operating in fast-moving retail or complex manufacturing, mastering inventory planning will lead to better decisions, happier customers, and a much stronger bottom line.

Make sure that what’s in store for your business, is optimised inventory planning.