Table of contents

Table of contents- How Slim4 is tackling top building materials industry challenges: real case studies in action

- Industry challenges in building materials supply chains

- Why building materials companies choose Slim4

- Slim4’s core solutions for building materials supply chains

- Success stories from the building materials industry

- Why Slim4 is the go-to for building materials supply chains

- Conclusion

Overview

The article details how Slimstock’s supply chain planning platform, Slim4, helps building materials companies overcome industry challenges like vast product ranges, erratic demand and long lead times. Slim4 provides AI-driven forecasting, end-to-end visibility and customised inventory solutions. Case studies from Technicel, Bouwmaat and Kapriol show that implementing Slim4 led to reduced obsolete stock, streamlined logistics, improved service levels and significant cost savings by automating replenishment and optimising inventory.

The building materials sector, which provides everything from sand and gravel to bricks, glass and specialised custom products, is the foundation of infrastructure development and construction. However, it’s a complex industry with vast product ranges, large inventories, erratic demand, long lead times and rising costs. Because of these difficulties, inventory and supply chain management requires constant balancing.

As the companies in the building material sector grow, solutions that provide control and visibility are key to further improving operations. Slimstock’s sharp supply chain planning platform, Slim4, was created especially to support them to continue success. As demonstrated by actual success stories from industry leaders, Slim4 helps businesses simplify complexity, cut costs, and improve service levels by combining sophisticated forecasting, real-time insides, and customised planning tools.

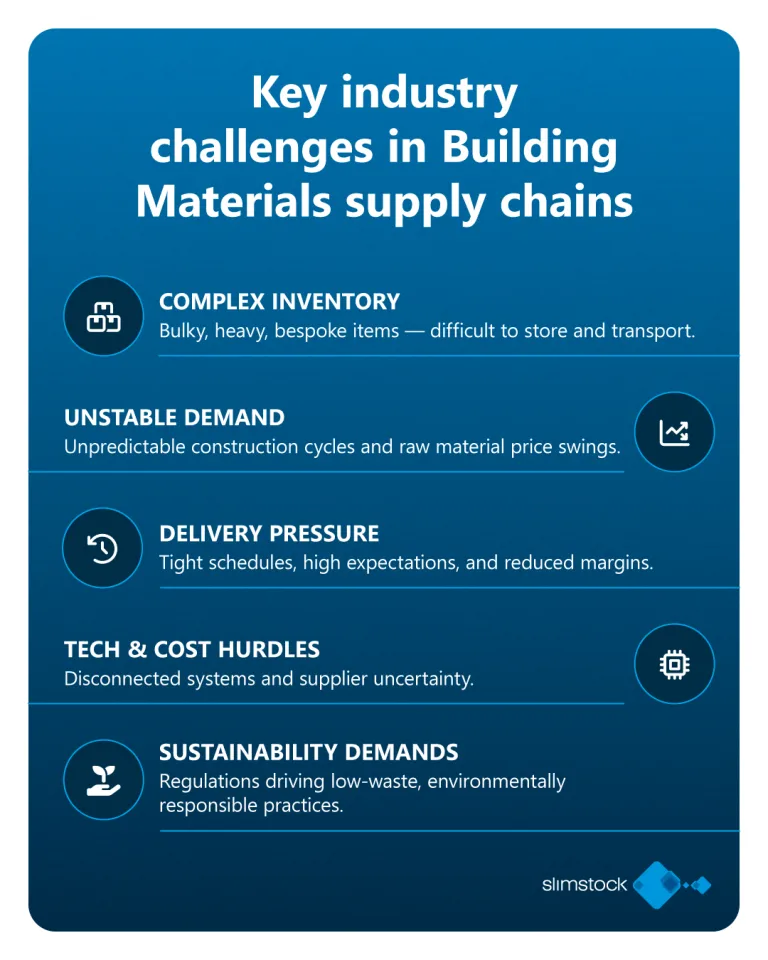

Industry challenges in building materials supply chains

In the building materials industry, inventory management is a challenging task. Businesses struggle with a wide range of products, many of which are heavy, bulky, or custom-made, and each has unique requirements for transportation and storage. Accurate demand forecasting can be challenging because of unstable building cycles, fluctuating raw material costs, and supply chain interruptions brought on by external factors.

Meeting customer expectations for on-time delivery, margin erosion, and supply shortages frequently cause executives to lose sleep. IT departments struggle with integrating complex systems and protecting data, while procurement teams deal with the challenge of managing growing costs in the face of supplier uncertainty.

Moreover, sustainability is no longer optional. With increasing regulations and environmental awareness, building materials companies must also minimise waste and embrace eco-friendly practices, adding a different layer of complexity to supply chain management.

Furthermore, sustainability is now required. Supply chain management is made more difficult by the need for building materials companies to minimise waste and adopt eco-friendly practices due to growing regulations and environmental awareness.

Why building materials companies choose Slim4

With more than 180 clients in the building materials industry alone, Slim4 has established a solid reputation for dependable, adaptable, and customised supply chain management. Companies choose Slim4 over rivals for the following main reasons:

Advanced demand forecasting

Slim4’s AI-driven predictive models anticipate market fluctuations, seasonal cycles, and construction project dynamics, enabling accurate forecasts despite volatile demand patterns.

End-to-end supply chain visibility

From procurement to final delivery, Slim4 provides clear visibility into supplier performance, inventory levels and stock locations, enabling businesses to make informed decisions

Industry-specific customisation

Recognising the diverse product types, from cement and timber to roofing materials, Slim4 tailors forecasting, planning and replenishment to fit the building materials sector’s unique operational realities.

Optimised order management

Slim4 improves supplier relationship management by tracking order fulfilment, lead times and supplier reliability, reducing delays and ensuring smoother procurement cycles.

Scalability and integration

Whether expanding product lines, distribution channels or data volumes, Slim4 grows with your business and integrates seamlessly with existing ERP and IT systems.

Slim4’s core solutions for building materials supply chains

Slim4 provides a range of features tailored to meet the key challenges faced by the building materials industry.

- Demand forecasting solution: Utilises AI and machine learning to predict future market needs accurately, factoring in seasonality, economic trends, and project-based demand surges.

- Demand planning tool: Aligns operational capacity with customer requirements to optimise product availability without overstocking.

- Purchase forecasting: Streamlines replenishment and supply processes across the entire logistics chain, reducing stockouts and excess inventory.

- Service level management: Dynamically defines and applies optimal service levels, balancing the cost of inventory with availability to maximise profitability.

- Economic Order Quantity (EOQ): Calculates ideal order sizes based on forecasted demand and service level targets to minimise costs and storage constraints.

- Order Generator (OG): Automates order creation, considering lead times, supplier constraints, and optimal reorder points for efficiency.

- Product Life Cycle (PLC) management: Tracks products from launch to discontinuation, reducing obsolete stock and aligning inventory with market demand shifts.

- Bill of Materials (BOM) and production planning: For manufacturers, Slim4 ensures seamless coordination between finished goods and raw materials/components for efficient production scheduling.

Success stories from the building materials industry

Let’s take a look at how Slim4 helped three building materials companies overcome their obstacles.

Technicel: managing complexity and growth

“Slim4 allows you to filter out gut feelings. We now use facts and data that cannot be denied. Slim4 is not a crystal ball, but it’s not far off.”

Andries Gysen

Purchasing & Operations Manager, Technicel

Since its establishment in 2005, Technicel, a provider of system solutions for expert floor installers, has experienced impressive growth. Technicel’s product line has grown to over 4,400 SKUs, and it currently operates nine stores, a distribution center, and an online store.

It was no longer feasible to manually manage such a large portfolio. Manual data analysis and daily stock checks overwhelmed inventory managers like Andries Gysen. Perishable items such as tile adhesive and grout, with limited shelf life, risked significant wastage.

Implementing Slim4 transformed Technicel’s inventory processes. The platform automated forecasting and replenishment, drastically reducing obsolete stock and unnecessary costs. It also shifted responsibility from individuals to structured systems, giving the company greater stability and peace of mind.

Most importantly, Slim4 enhanced internal collaboration. Sales teams, once reliant on instinctual ordering, now work alongside purchasing with reliable data at their fingertips, resulting in more accurate stock decisions. Technicel reports improved service levels and freed-up resources, enabling further growth.

Bouwmaat: transforming supply chain collaboration and efficiency

“We have cut deliveries from our branches by 60%, which has saved us a tremendous amount of time and money”

Jeroen de Haan

Supply Chain & IT Manager

Bouwmaat, a prominent wholesaler of building materials with 47 locations throughout the Netherlands, encountered its own set of difficulties. The business had trouble with inefficiencies and irregular stock availability when it was using a decentralized supply chain.

Bouwmaat significantly streamlined its supply chain by implementing Slim4 and centralising distribution through a new warehouse. The platform made it easier for suppliers and logistics companies to share sales, forecast, and inventory data in real time.

This openness improved supplier delivery performance, streamlined logistics planning with Ceva Logistics, and helped avoid upstream overstocking. In addition to cutting deliveries to branches by 60%, Bouwmaat now boasts an impressive 99% service level, which translates into significant cost savings.

Jeroen de Haan, Bouwmaat’s supply chain manager, emphasises the value of open communication: “Sharing inventory information with partners always pays off.” This collaborative approach enables better customer service by offering accurate stock availability and delivery expectations.

Kapriol: boosting sales and cutting stock levels with tailored planning

“Thanks to Slimstock’s expertise and the capabilities of Slim4, we have not only achieved our initial goals but unlocked new opportunities to optimise our supply chain and grow strategically.”

Alberto Morganti

CEO

Kapriol, a renowned supplier of protective equipment with over 5,000 products and presence in 70 countries, sought to optimise its inventory while maintaining high service levels amid erratic demand.

Partnering with Slimstock, Kapriol customised forecasting algorithms to fit its unique needs. The results were impressive: a 97% service level despite a 13% reduction in inventory coverage, freeing up cash tied in stock, alongside a 15% increase in average sales.

Integrated reporting tools empowered the company to identify exceptions and make data-driven operational decisions. CEO Alberto Morganti praised Slim4’s role in unlocking new strategic opportunities and streamlining supply chain tactics.

Looking ahead, Kapriol plans to further enhance forecasting accuracy and agility by continuing collaboration with Slimstock — ensuring they remain competitive in a fast-changing global market.

Why Slim4 is the go-to for building materials supply chains

From sprawling SKUs and bulky inventories to volatile markets and sustainability pressures, the building materials industry demands robust, agile supply chain solutions. Slim4 delivers on these fronts by:

- Providing accurate, AI-driven demand forecasting and inventory optimisation.

- Enabling end-to-end visibility and collaboration across suppliers, logistics, and sales.

- Reducing waste, overstocking, and obsolete stock, improving cost control.

- Supporting sustainability goals with smarter material management

- Scaling with businesses as they grow, adapting to complex and diverse portfolios.

- These benefits, proven in multiple case studies, make Slim4 a powerful ally for any building materials company aiming to sharpen its competitive edge.

Conclusion

The building materials industry stands at a crossroads: facing rising costs, global uncertainties, and growing environmental expectations. Embracing digital transformation through solutions like Slim4 is no longer optional but essential to thrive.

With its proven ability to optimise inventory, improve collaboration, and reduce costs, Slim4 empowers companies to tackle industry challenges head-on. Whether you’re a growing supplier like Technicel, a wholesaler transforming your supply chain like Bouwmaat, or an international player like Kapriol, Slim4 provides the tools to build a more efficient, sustainable, and resilient future.

Are you ready to see how Slim4 can transform your building materials supply chain? Let’s start the conversation today!