Table of contents

Table of contents- What is stock level and what is the best formula to achieve an optimal stock level?

- What is stock level?

- What is optimal stock?

- What is the relationship between optimal stock and inventory optimisation?

- Who needs to optimise their inventory?

- How to calculate optimal stock?

- Optimal stock by industry: retail, pharmacy and automotive

- Examples of optimal stock

- How do demand and product life cycle affect optimal stock?

- What about the introduction of new products and promotions?

- Ensuring high availability as an indicator for optimal stock

- FAQs about stock level

Overview

Optimal stock is the ideal inventory level that efficiently meets demand while minimizing storage and management costs. The basic formula to calculate optimal stock, also known as the reorder point, is: (Average daily demand × Lead time in days) + Safety stock. Achieving this balance requires continuous monitoring, adjustment and consideration of industry-specific factors, demand variability and product life cycles, as sub-optimal stock can lead to lost sales, tied-up capital and obsolescence.

Companies face various challenges when managing their inventory, but there is one universal need that they all share: the constant quest to maintain optimal stock levels. In the following lines, we will explore this vital concept in inventory management, analyse in detail how to achieve and maintain optimal stock levels, examine how they are calculated, and look at practical examples, examining both the common aspects and the particularities of these sectors.

First, it’s important to define some fundamental concepts, such as stock level and inventory optimisation. Understanding these terms will provide the basis for exploring how to maintain the ideal stock level.

What is stock level?

Stock level refers to the amount of inventory a company has at any given time. It’s a crucial metric for businesses to track, as it helps ensure they can meet customer demand without overstocking.

What is optimal stock?

Optimal stock in a warehouse refers to the level of inventory considered ideal for meeting product demand efficiently, minimising costs associated with storage and inventory management. This stock level is determined by balancing several factors, including anticipated product demand, supplier lead times, storage costs, ordering costs and the need to avoid stock shortages.

The goal of optimal stock is to ensure that a company has enough products in its warehouse to meet customer demand without incurring unnecessary costs related to excess inventory. Maintaining optimal stock helps maximises operational efficiency and ensures products are available when customers need them, thereby improving customer satisfaction and profitability.

What is the relationship between optimal stock and inventory optimisation?

Optimal stock and inventory optimisation are closely related, as both concepts focus on ensuring that a company has the right amount of products in its warehouse to meet demand efficiently and profitably.

Stock optimisation is a process that aims to achieve maximum availability of our inventory with minimum investment in stock. In other words, it is about being able to have just the right inventory to offer the desired level of service at all times for all our references.

Here is an explanation of how they are related:

Common goal

Both optimal stock and inventory optimisation have the primary goal of minimising total inventory costs while ensuring that products are available when customers need them. Inventory optimisation seeks to find the right balance between investment in inventory and customer satisfaction, and optimal stock is part of that process.

Determining stock levels

Inventory optimisation involves determining the optimal stock level for each product based on factors such as historical demand, lead times, storage costs and ordering costs. This optimal stock level is what is known as “optimal stock.” Therefore, inventory optimisation is the process by which optimal stock is calculated and sought to be maintained.

Continuous monitoring and adjustment

Both optimal stock and inventory optimisation require constant monitoring and adjustments as necessary. Demand and other factors can change over time, so it is important to adapt the stock level to keep it in line with inventory optimisation objectives.

Improved efficiency

Inventory optimisation, including determining and maintaining optimal stock levels, seeks to improve a company’s operational efficiency. This involves reducing unnecessary storage costs, minimising ordering costs and avoiding stock shortages or excesses.

Customer satisfaction

By ensuring that products are available when customers need them, both optimal stock levels and inventory optimisation contribute to improved customer satisfaction. Customers are more satisfied when they can obtain the products they want in a timely manner, without delays or stockouts.

In this regard, we can ask ourselves the following question…

Who needs to optimise their inventory?

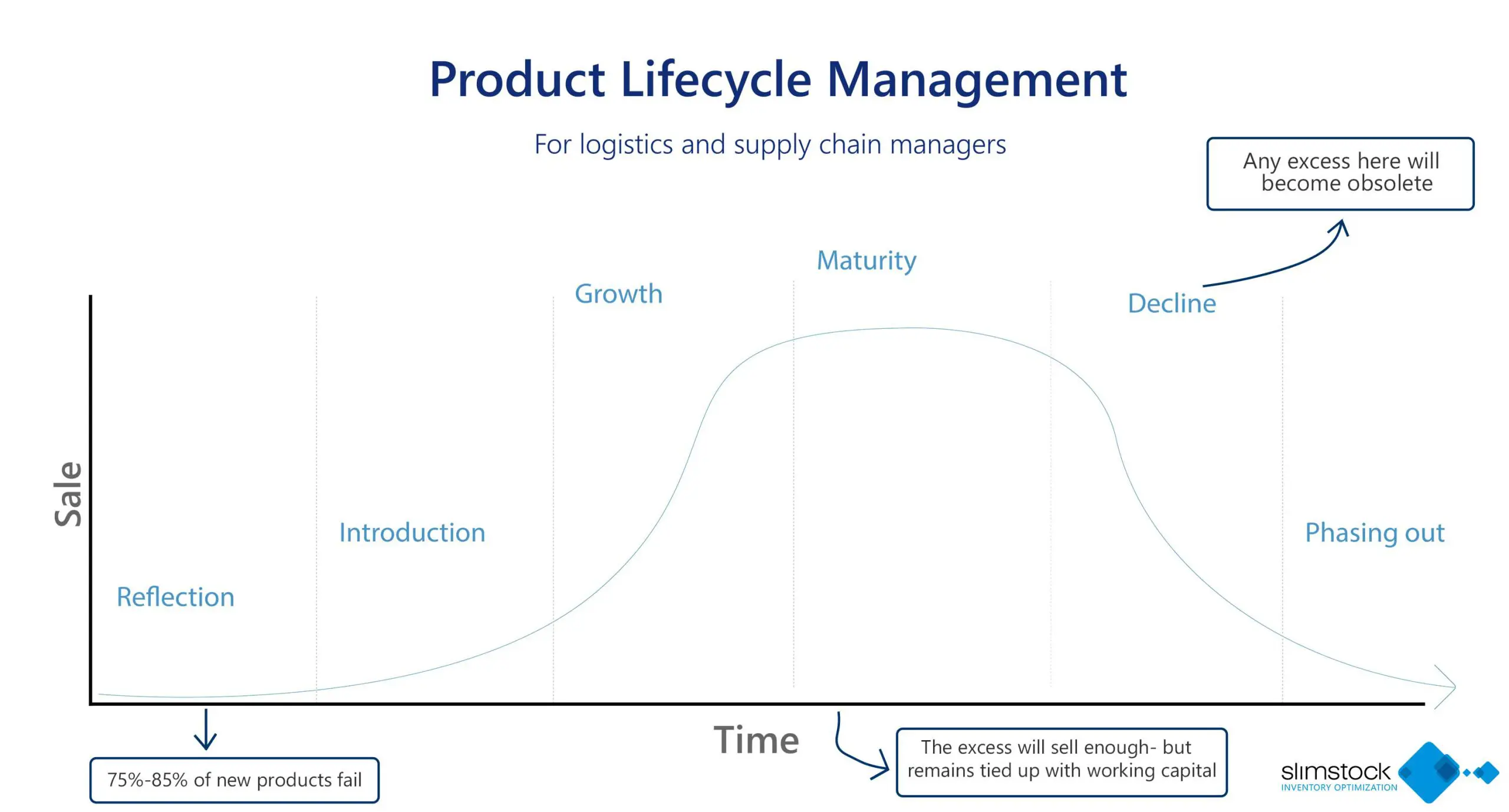

Any company that works with stock references and independent demand, i.e., that does not know what reference or quantity will be requested at any given time, needs to optimise its inventory. Otherwise, sub-optimal inventory causes serious operational and financial difficulties. Shortages lead to lost sales and even lost customers, while stock ties up our capital. Furthermore, excess stock leads to obsolescence, which destroys the company’s profitability. If we add the current economic situation to these factors, optimisation becomes more than important, it becomes essential.

However, companies usually manage their inventories by taking into account the demand forecasts generated by their ERP systems and/or their sales teams. Unfortunately, this way of working does not have the appropriate forecasting and safety stock calculation models that would allow them to manage the behaviour of each of their references. The result: countless hours of work that ultimately yield poor results.

How to calculate optimal stock?

Calculating optimal stock, also known as the reorder point, involves considering several key factors to determine the amount of inventory that should be kept in the warehouse.

Optimal stock level formula

Here is a basic formula for calculating optimal stock:

Let’s look at what each of these components means:

Average daily demand

This value represents the average number of units sold or used per day. To calculate it, you can take the total demand over a period of time (e.g., one month) and divide it by the number of days in that period. This will give you an estimate of how much is needed on a typical day.

Lead time in days

This is the time that elapses from when an order is placed until the goods are received at the warehouse. It can vary depending on the supplier and logistics. You must take into account the time it takes to obtain new products once an order has been placed.

Safety stock

Safety stock is an additional amount of inventory that is kept to cope with variability in demand and delivery times. It is a precaution to avoid stockouts. The level of safety stock can be determined based on historical demand variability and variability in delivery times. The greater the uncertainty, the greater the safety stock should be.

Once you have calculated these three components, simply add the Average Daily Demand multiplied by the Lead Time in Days and the Safety Stock. The result will give you the amount of inventory you need to have on hand to ensure that you do not run out of products before a new order arrives and to cope with possible variations in demand or delivery times.

It is important to remember that this calculation is a simplification, and that inventory management can become more complex in real business environments due to other factors, such as costs associated with storage, replenishment strategies, and seasonality of demand. In addition, it is essential to regularly review and adjust the optimal stock calculation as business conditions and demand trends change.

Optimal stock by industry: retail, pharmacy and automotive

What do a retail chain, a pharmaceutical distributor and an automotive parts wholesaler have in common? On the surface, not much, but it is clear that they all share one need: to work with optimal stock.

For all of them, a shortage is a shortage, excess stock is excess, and obsolete stock is obsolete. However, each of them has particularities that must be taken into account in order to achieve stock optimisation in line with their business.

Both the number of references we manage and the number of stock points we work with make it difficult to manage inventory correctly as they increase. Each reference has specific behaviour in each location and, therefore, its forecast and optimal stock must be calculated according to the industry.

The companies that encounter the most difficulties are those that manage thousands and even millions of SKUs (location-item combinations). In this case, both retailers and distributors of pharmaceutical products and automotive parts manage a large number of SKUs and multiple points of sale, which can mean millions of SKUs in some cases.

Therefore, the more SKUs, the greater the complexity; the greater the complexity, the greater the need for information; and the greater the need for information, the more time we need to invest in managing SKUs.

Examples of optimal stock

The calculation of optimal stock can vary depending on the industry, the type of product, and the specific circumstances of each company.

Here are some examples of how the concept of optimal stock could be applied in different contexts:

Retail

Suppose a retail store sells electronic products, such as mobile phones. The average daily demand for a particular phone model is 20 units. The delivery time from the supplier is 5 working days.Based on historical sales analysis and fluctuations in demand, the company has determined that it needs to maintain a safety stock of 10 units.

The optimal stock calculation would be:

Therefore, the company should have at least 110 units of that phone model in stock at all times to meet demand and mitigate uncertainty.

Pharmaceutical distribution

A pharmaceutical distribution company supplies medicines to several pharmacies. The average daily demand for a medicine is 30 units. The delivery time from the manufacturer is 2 days. Due to the critical importance of some medicines, the company maintains a high safety stock of 50 units.

The optimal stock calculation would be:

The company should maintain at least 110 units of that medicine in stock at all times.

Automotive parts wholesaler

An automotive parts wholesaler sells spare parts to car repair shops. The average daily demand for an oil filter is 15 units. The delivery time from the supplier is 3 days. The company has calculated that it needs a safety stock of 20 units due to seasonal variability in demand.

The optimal stock calculation would be:

Therefore, the wholesaler should keep at least 65 units of oil filters in stock at all times.

These are only simplified examples. In real situations, inventory management involves additional considerations, such as inventory turnover, storage costs and ordering costs. In addition, optimal stock levels may vary for different products and situations within the same company. The key is to tailor the optimal stock calculation to the specific needs and circumstances of each business.

How do demand and product life cycle affect optimal stock?

Everyone wants to work only with high-turnover, high-margin items, but the very nature of the business and the life cycle of its products force companies to maintain different compositions of high-, medium- and low-turnover items.

In the case of retailers, the dynamics of their business mean that they tend to keep high-turnover items, which they normally achieve in their distribution centres, although at their points of sale we again find erratic and irregular behaviour. Not to mention display items such as glasses, perfumes, etc.

In pharmaceutical distribution, we find a combination of high, medium and low turnover items. Although theoretically there is clear potential for improving the composition of the assortment, market constraints are usually decisive.

The most complicated scenario is that of spare parts wholesalers. The nature of spare parts means that distributors in this sector work with many slow-moving or irregular items, with the added complication of very long product life cycles, favouring the famous Long Tail effect. In this case, it is important to closely monitor the (negative) trend of these items, discontinuing them in time to prevent them from becoming obsolete.

What about the introduction of new products and promotions?

The introduction of products and promotions is an indicator of optimal stock levels. If we compare the three sectors, while a retailer launches several catalogues per year and offers numerous promotions, a spare parts distributor has an obligation, at least from a business point of view, to keep a reference in stock for many years, while pharmaceutical distribution would fall somewhere in the middle of this spectrum.

This means that for a retailer, the introduction of new products and the management of promotions are aspects of utmost importance, indicators for optimal stock levels. The renewal of a large part of their assortment every few months and the launch of constant promotions make it necessary for the stock optimisation system to allow new items and promotions to be introduced easily, taking into account past promotions and substitute or related products.

In pharmaceutical distribution and spare parts wholesalers, the introduction of new items and promotions is less frenetic, but still very important. Based on all this, we should confirm whether we have a way to manage the introduction of new products. A good way to do this is to ask ourselves the following questions:

- Can we copy the historical demand for substitute or predecessor items?

- Can we copy the historical demand for substitute or predecessor items?

- What about the management of promotions and other commercial actions?

- How can we add the additional demand from a future promotion to the existing forecast?

- Do we take into account the cannibalisation effect that the promotional item may have on other items?

- Do we take into account post-promotional behaviour?

Are we able to separate promotional demand from normal historical demand, so that promotions do not influence the calculation of demand forecasts for future cycles?

Ensuring high availability as an indicator for optimal stock

Although ensuring high availability is part of the indicators for optimal stock for any sector, for a retailer it is essential, as a shortage means a lost sale. This has been exacerbated in recent years with the rise of online shopping. Retailers who do not sell online compete against websites that offer a wide range of products with immediate availability. And if they do have an online store, they have to achieve just that: be able to offer a wide range of products that are immediately available.

In the case of pharmaceutical distributors and spare parts wholesalers, shortages also often result in lost sales.

How can I avoid stockouts? Do we realise when an item is running low on stock? At the moment of the stockout or before, so that we can react preventively to avoid the stockout? Can we detect items with excess stock? Or items at risk of becoming obsolete? What is the relationship between the availability of an item and the stock needed to guarantee this availability? Is there such a thing as optimal stock?

FAQs about stock level

What is stock level?

Stock level refers to the amount of inventory a company has at any given time. It helps businesses manage the balance between supply and demand, ensuring they have enough products available without overstocking, which can lead to higher costs and wasted capital.

What is stock optimization?

Stock optimization is the process of managing inventory to ensure maximum product availability with minimal investment. It involves finding the right balance between having enough stock to meet customer demand and avoiding excess inventory that can tie up capital and increase costs.