Table of contents

Table of contents- The Pareto Principle and its application in the Supply Chain

- What is the Pareto Principle?

- Examples of the Pareto Principle

- Benefits of applying the Pareto Principle

- Focusing on what matters: the case of Distrivet

- Applying the Pareto Principle to inventory management

- Common mistakes in applying the ABC method

- Conclusion: focus your efforts on what matters

- FAQs about the Pareto Principle

Overview

The Pareto Principle, or 80/20 Rule, states that roughly 80% of outcomes result from 20% of causes. In the supply chain, this means focusing on the 20% of products that generate 80% of revenue to optimize resources, improve decision-making and increase profitability, often implemented through ABC analysis for differentiated inventory management.

Work smart, not hard. This widely popular phrase in today’s corporate world—emphasising the importance of focusing efforts on what truly delivers results—neatly sums up the essence of the Pareto Principle.

The Pareto Principle suggests that 80% of outcomes stem from just 20% of the causes. To support this idea, Vilfredo Federico Damaso Pareto conducted various empirical studies. The most well-known of these was his observation that approximately 80% of Italy’s land (and therefore its agricultural yields) was owned by just 20% of the population. It is also said that he noticed a similar pattern in his own garden, where 20% of the plants were responsible for producing 80% of the fruit. This idea—that 20% of actions or causes drive 80% of results—is why the Pareto Principle is also commonly referred to as the 80/20 rule.

When applied to supply chain management and inventory control, this principle suggests that eight out of every ten euros in revenue come from just 20% of the product range. But we’ll delve deeper into this later in the article.

What is the Pareto Principle?

As we mentioned earlier, the Pareto Principle is a statistical idea that explains how results are often unevenly distributed—typically in an 80/20 split—where a small number of causes lead to most of the effects. This concept was introduced by the Italian economist Vilfredo Pareto in the late 19th century.

It’s not a strict mathematical rule but more of a helpful guideline for spotting patterns of imbalance. The exact ratio isn’t always 80/20—it could be 70/30 or even 90/10—but the key takeaway is the same: a small portion of inputs tends to drive the majority of outcomes.

By applying the Pareto Principle, businesses and individuals can use resources more effectively, set the right priorities, and focus on what truly makes a difference.

Examples of the Pareto Principle

The Pareto Principle can be seen in many different areas. Here are some of the most common examples:

1. In business management

In business, it’s often the case that 20% of internal processes lead to 80% of operational results. A small number of strategic initiatives tend to drive most major improvements in a company. Likewise, a small percentage of employees often account for the bulk of productivity, which is why it’s so important to recognise and retain top talent.

2. In marketing

Marketing strategies also follow this pattern. Usually, 20% of campaigns generate around 80% of the overall impact. The same applies to web traffic, a handful of keywords tend to bring in most of the visitors to a website.

3. In supply chain

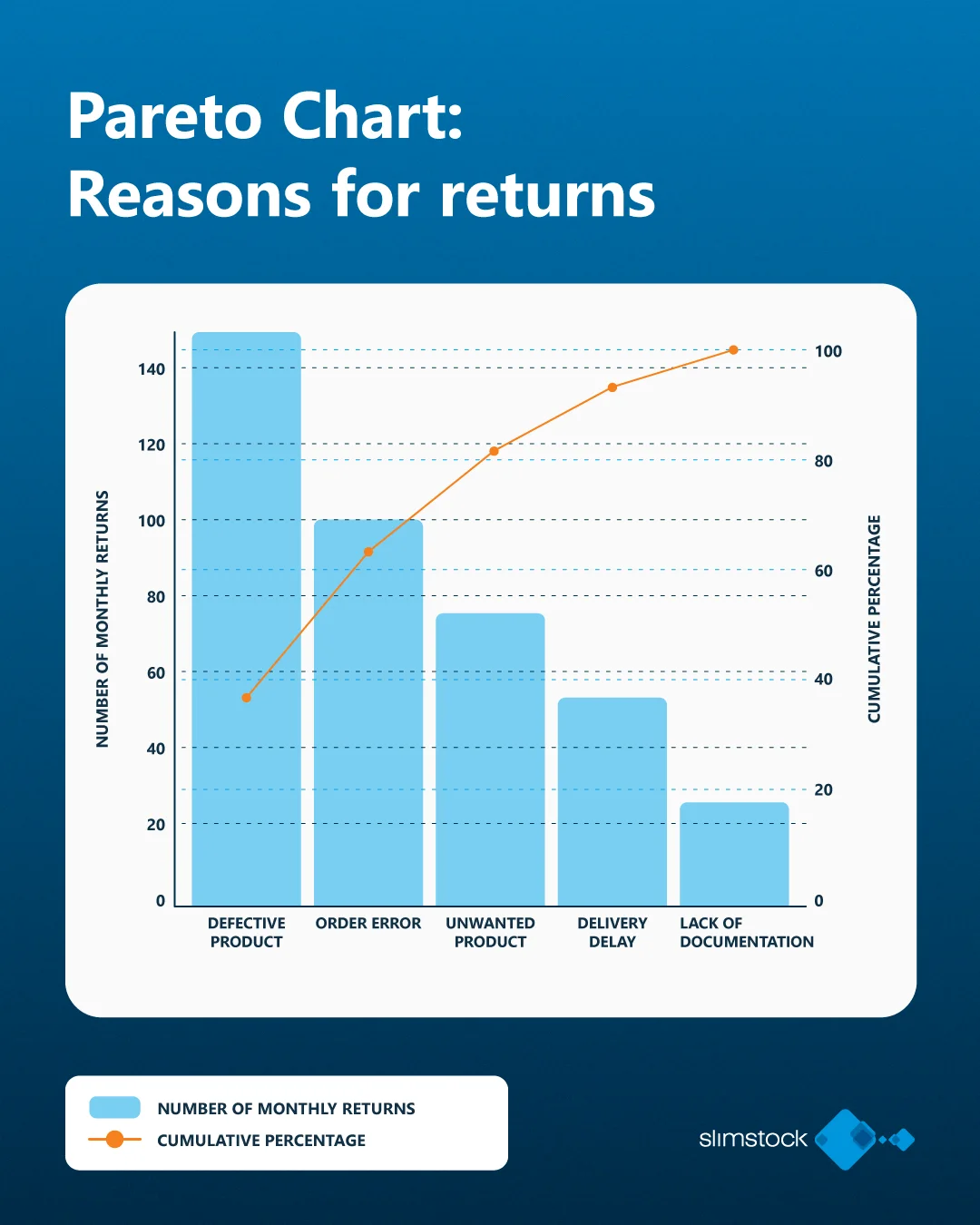

When managing inventory, companies often find that a small number of products make up the majority of total stock value. Because of this, it makes sense to focus more attention on those key items. We’ll look at this in more detail later, along with how the ABC method can help businesses manage their product range more effectively.

Similarly, in procurement, 20% of suppliers are typically responsible for 80% of total purchases, making it essential to build strong relationships with these key partners.

4. In daily life

The Pareto Principle can also be applied to our everyday lives. For example, 20% of the tasks we do in a day often lead to 80% of the results we achieve. Similarly, in our professional networks, it’s typically 20% of the people who provide most of the job or business opportunities. This highlights the importance of nurturing and strengthening those key relationships.

These examples show how the Pareto Principle can help identify the areas where we should focus our efforts, optimising resources and maximising results.

Benefits of applying the Pareto Principle

In business, the Pareto Principle offers a range of practical and strategic benefits.

Resource optimisation

One of the main advantages is the optimisation of resources. By applying the Pareto Principle, organisations can pinpoint the areas that have the biggest impact and focus their efforts there. This helps avoid wasting time on unproductive activities and ensures better overall performance.

Improved decision-making

Another key benefit is improved decision-making. By relying on data that identifies the key drivers behind outcomes, companies can make better-informed and more strategic decisions, positioning themselves more effectively in the market. This approach also enhances operational efficiency, as it helps streamline processes and eliminate bottlenecks, ensuring that resources are directed where they matter most.

Higher profitability

When it comes to profitability, focusing on the 20% most valuable products or customers allows companies to significantly increase their profit margins. This is also supported by cost reductions, as businesses stop investing resources in low-impact activities or products and instead redirect that budget to more effective initiatives.

More satisfied customers

Applying the Pareto Principle can also greatly improve customer satisfaction. By focusing on the products, services, or processes that deliver the most value to customers, businesses can strengthen their relationships with them, leading to greater loyalty and a more positive brand perception.

Focusing on what matters: the case of Distrivet

Distrivet, a leader in the distribution of veterinary products in Spain and Portugal, has seen significant improvements in its supply chain by applying the Pareto Principle and streamlining its product range. By implementing Slim4, the company has optimised its inventory management, focusing on the most critical products that account for the largest portion of its stock value.

This strategy has enabled Distrivet to achieve a 99% service level, a 16.5 percentage point increase since the implementation, while reducing its inventory by 17%. This translates to 5 million euros less tied up in stock. Additionally, stock days have decreased by 40%, reflecting a more efficient approach that focuses on the highest-impact products.

Applying the Pareto Principle to inventory management

A common challenge in inventory management is deciding which products to focus on. Companies often end up investing too much money in products that don’t add significant value, while the ones that really matter might not receive the attention they need. This is where ABC analysis comes in, a methodology that helps us prioritise products and optimise our supply chain.

Differentiated inventory management

One of the clearest advantages of ABC analysis is that it enables differentiated inventory management. For A products, much stricter inventory policies are implemented. This might include daily or weekly inventory reviews, along with more frequent replenishment policies to ensure these key products are always in stock.

Optimising inventory and reducing costs

ABC analysis helps us optimise our inventory levels, particularly when it comes to C products, which often make up a large portion of storage costs without adding much value. By keeping these products at minimal levels or managing them on demand (if possible), we can free up warehouse space and reduce the capital tied up in stock.

Demand planning

With ABC analysis, we can also improve our demand planning. Knowing which products are most important allows for much more accurate forecasting. For example, if we know that A products are critical to the business, we can ensure our demand planning processes are finely tuned for those items. In contrast, C products can be managed less frequently, reducing costs and complexity.

Common mistakes in applying the ABC method

Many companies use ABC analysis, but that doesn’t always mean they’re making the most of the information it provides or applying it correctly. In fact, here are some of the most common mistakes made when carrying out traditional ABC analysis:

Insufficient demand forecasting control

A common mistake is focusing solely on historical data without considering future demand forecasts in the ABC classification. What happens, for instance, with trending products? If we only rely on past data, we risk misclassifying items that are on the rise or those on the decline. And what about seasonal items? If we’re approaching the peak season for a seasonal product and only looking at past data, our classification and subsequent decisions won’t align with the product’s current situation.

Relying on a single analysis criterion

We’ll go into more detail on this later, but it’s crucial not to base everything on just one criterion. It’s essential to cross-reference different criteria to make sure the results are much more accurate and valuable for the company.

Failing to update the ABC analysis

In many cases, the ABC analysis is done at a specific point in time and then left unchanged for weeks or even months. It’s just as important to set the right rules for classification as it is to establish the processes for regularly updating the analysis. The frequency of updates will depend on each company, but it’s important to define this optimal update cycle.

Conclusion: focus your efforts on what matters

If you’re a regular reader of this blog, you’ll know that we stress the importance of professionals in the supply chain focusing on what truly matters. That’s why we emphasise that operations teams shouldn’t waste time putting out fires, but instead adopt an management by exception system.

When it comes to managing product ranges, the Pareto Principle helps us focus on what’s most important. In other words, it helps us concentrate on that small percentage of products that generate the majority of the impact, whether it’s in sales, profitability, or turnover.

Applying the Pareto Principle in range management allows us to prioritise resources for key items, optimise inventory, and design more effective strategies to maximise results. In short, by leveraging the Pareto Principle to our advantage, we can simplify operations and focus on what really adds value to the business.

FAQs about the Pareto Principle

Is the Pareto Principle applicable in all sectors?

Yes, the Pareto Principle is applicable across most sectors, although the exact ratio (80/20) may vary depending on the context. For example, in inventory management, it could be 70/30 or 90/10. Its versatility lies in identifying key areas where a small portion of elements produces the greatest impact.

Is the Pareto Principle a strict rule?

No, the Pareto Principle is not a strict rule, but rather a statistical concept. The exact ratio can vary, and its effectiveness depends on analysing specific data within a given context. However, its core idea remains the same: a small number of factors generates the majority of the results.

How does the Pareto Principle benefit decision-making?

The Pareto Principle helps make more informed decisions by identifying the areas with the greatest impact. It allows organisations to prioritise efforts, optimise resources, and focus on activities that create value, reducing costs and improving operational efficiency.