Table of contents

Table of contents- Blueprint: Supply and demand flows in the supply chain

- Why does the blueprint matter?

- What is a supply chain blueprint?

- What elements make up a blueprint

- What data does a blueprint collect (or need)?

- What is a blueprint used for in practice?

- Blueprint: A basic element for supply chain planning

Overview

This article explains what a supply chain blueprint is and why it matters. It describes how a blueprint visually represents logistics networks, including suppliers, customers, facilities and material flows, and how it defines the fundamental rules that govern demand, supply, and decision-making in a supply chain.

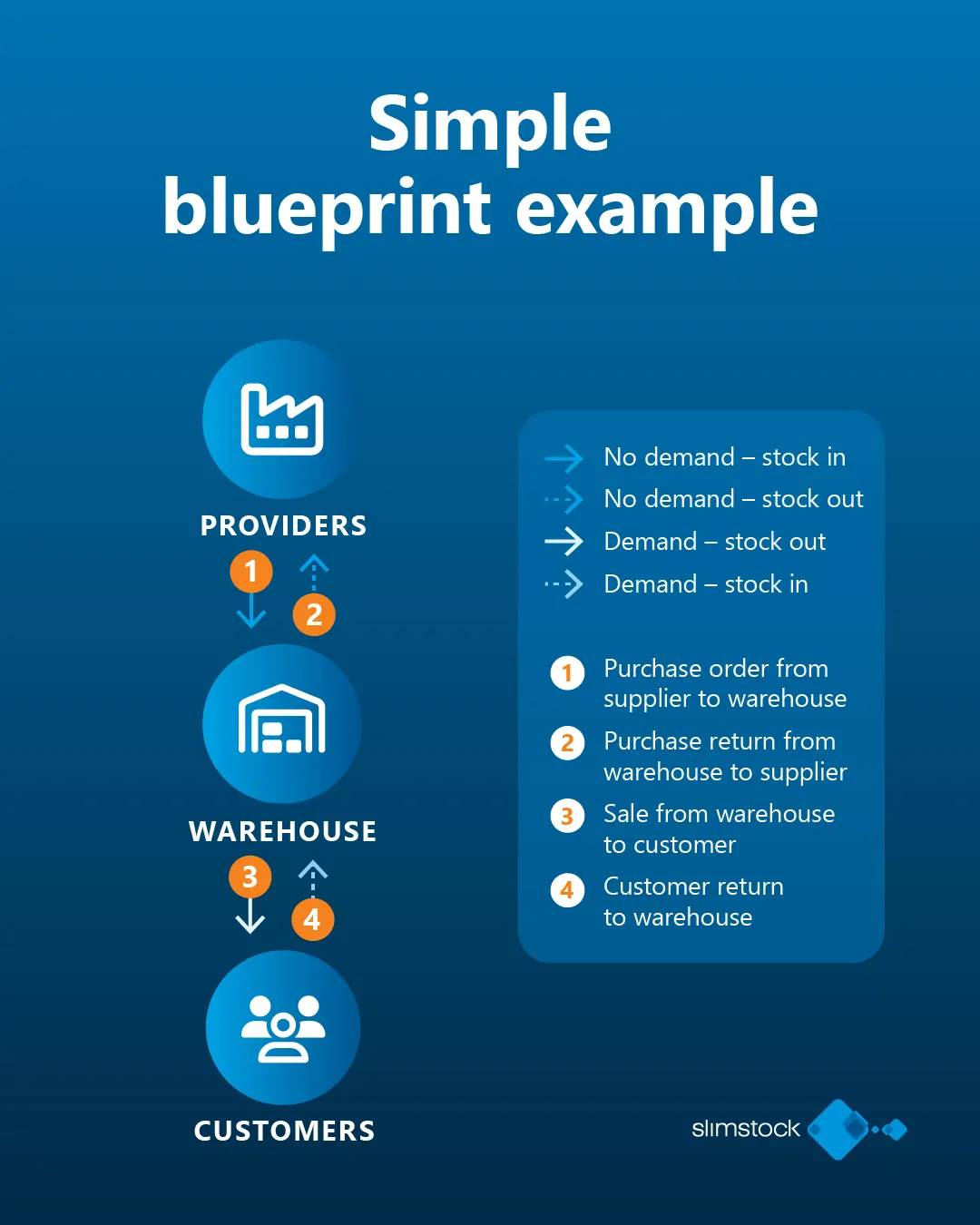

In any company, the supply chain is built on two main types of flows: demand, which reflects what the market requires, and supply, which shows how the organisation sources its inputs to meet that demand. In the simplest structures, these flows are usually easy to follow: a single warehouse, a few suppliers and a direct sales channel to the end customer. In these cases, the relationship between what is sold and what is purchased is quite obvious.

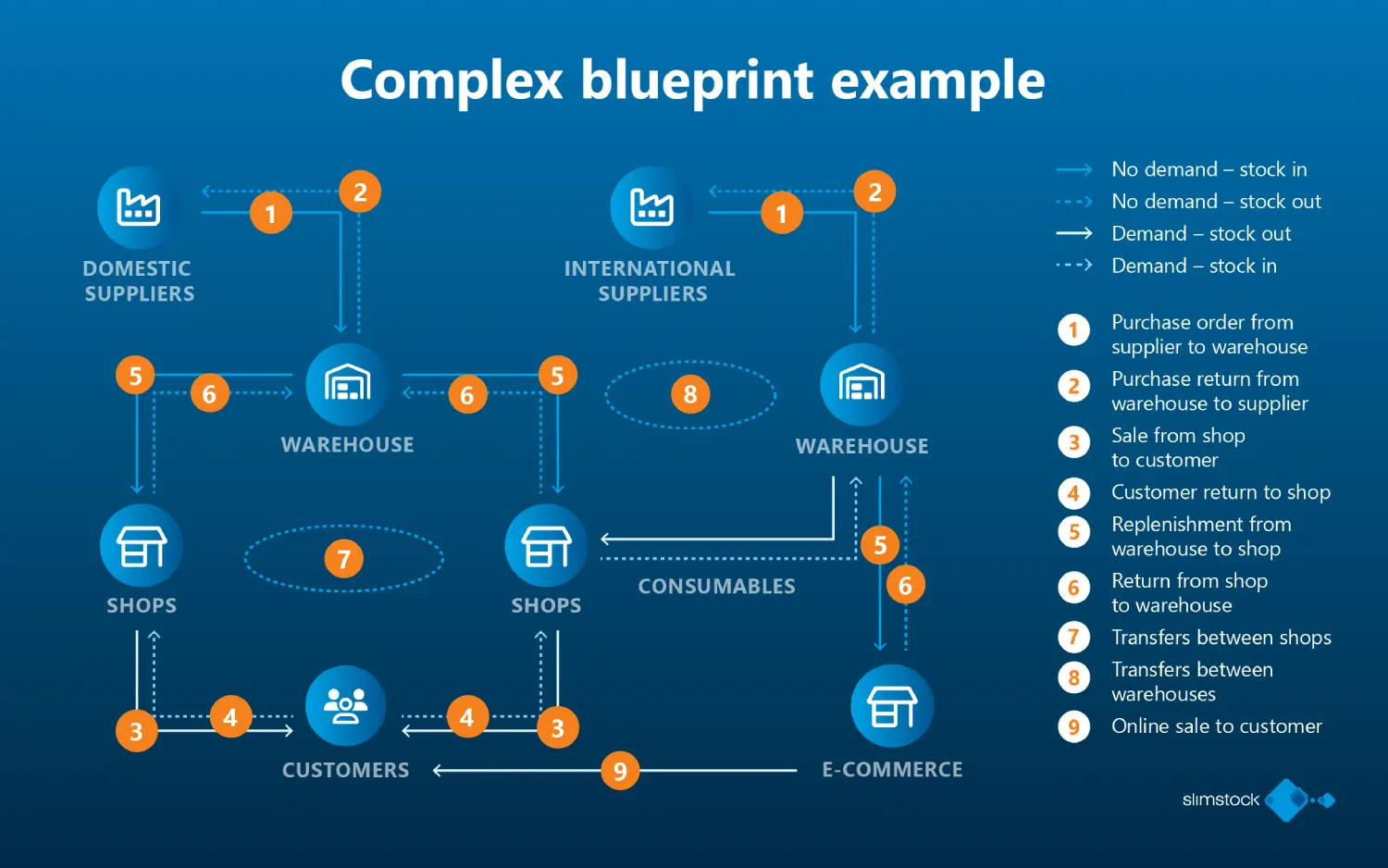

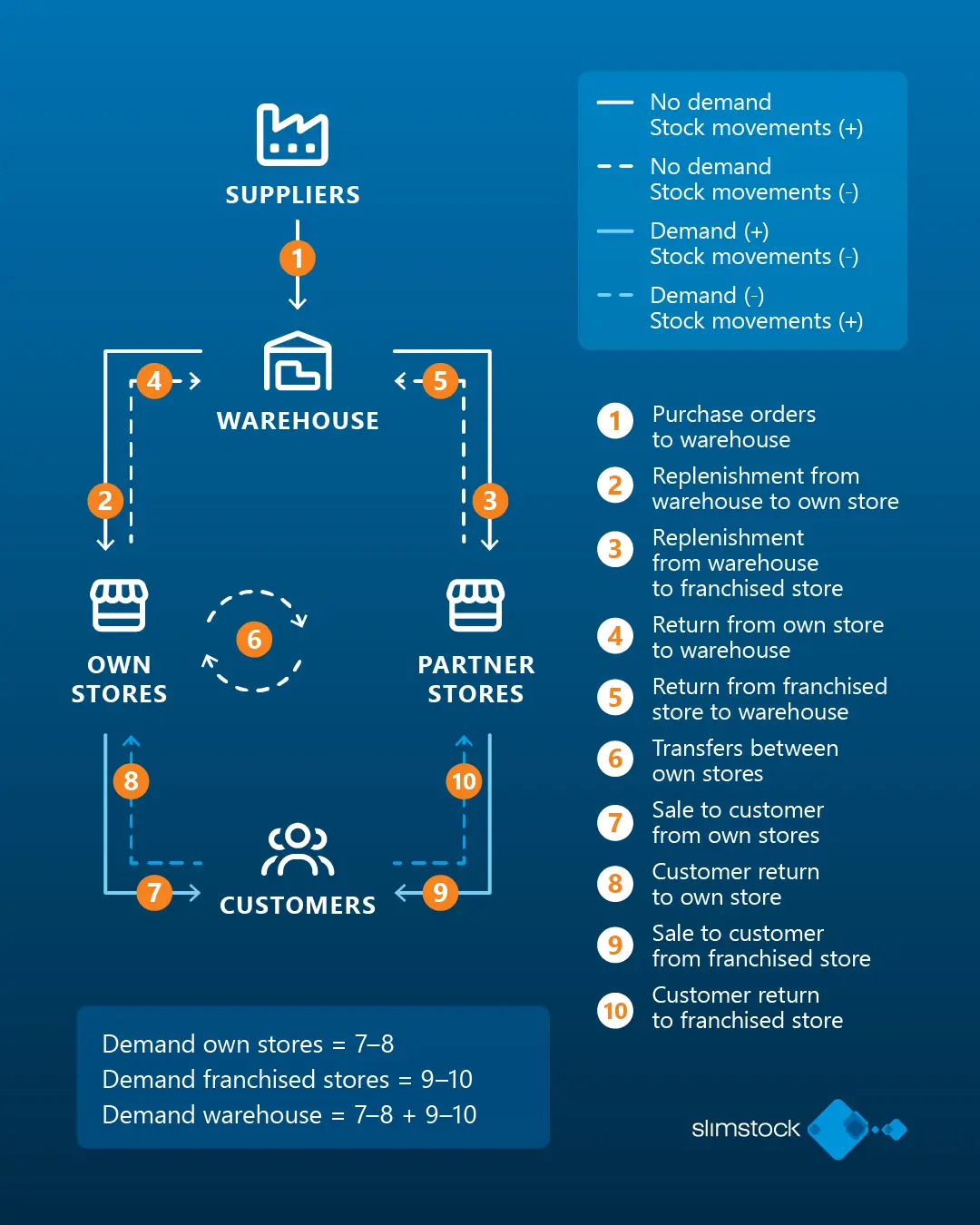

However, as the company grows, incorporates new logistics centres, opens stores, adds sales channels, introduces its own production facilities or works with different suppliers, the reality becomes much more complex. Internal transfers, cross-returns, replenishments between centres, production flows and operational exceptions appear, making it less obvious where demand is actually generated or how stock is replenished.

In this type of environment, relying solely on intuition or a partial view of the data can lead to misinterpretations and unreliable planning decisions. That is why many organisations turn to a key tool: the blueprint. This tool provides a structured and understandable representation of all the demand and supply flows that define the actual functioning of the supply chain.

Why does the blueprint matter?

In many optimisation projects, people start talking about forecasting, stock or service without being entirely clear about how demand and supply actually flow within the organisation. The result is often predictable: models that are difficult to explain, indicators that do not add up and decisions that generate more noise than value.

This is where the blueprint comes in. It is not a dashboard or a KPI report, it is something more fundamental, and at the same time more strategic: a clear and shared map of how the company’s logistics network works.

In this article, we explain what a blueprint is, what information it collects, what it is used for and why it is a key part of any planning and optimisation project.

What is a supply chain blueprint?

A blueprint is a structured representation of the logistics network and the flows that run through it. It describes, in a visual and logical way, how the elements are connected:

- Logistics and production centres.

- Customers.

- Suppliers.

- Demand flows.

- Supply flows.

- Internal movements.

Its purpose is not to detail operational processes exhaustively, but rather to define the rules of the game: what is considered demand, what is supply, what movements consume stock and where decisions are made.

In other words, the blueprint answers the question, “How does our supply chain work?”.

What elements make up a blueprint

Although each company has its own complexities, most blueprints are composed of the same elements.

1. Network nodes

These are the points where stock is held or decisions are made:

- Central warehouses.

- Regional branches or warehouses.

- Factories or production plants.

- Raw material centres.

- External platforms or 3PLs (if any).

Each node must have a clear role: a centre that sells to end customers is not the same as one that only redistributes between warehouses or other production sites.

2. Demand flows

The blueprint clarifies which movements represent actual demand. This usually includes:

- Sales orders to customers.

- Returns, which reduce net demand.

One of the key advantages of the blueprint is that it forces demand to be formulated in a consistent manner, for example:

Demand = Sales – Returns

3. Supply flows

This represents all the ways in which stock enters the network:

- Purchases from external suppliers.

- Internal production.

- Entries from other centres.

The blueprint clearly separates demand from supply, which is essential in order not to confuse consumption with replenishment.

4. Relationships between centres

The blueprint shows who supplies whom:

- Which warehouses are replenished from a central warehouse.

- Which centres can purchase directly.

- Where production is supplied from.

- Where stock is consolidated.

This is especially relevant in multi-warehouse or multi-level environments, where a misinterpretation of these relationships can distort the entire planning process.

What data does a blueprint collect (or need)?

Although the blueprint is usually represented as a visual diagram, its usefulness does not depend on the drawing itself, but on the quality and consistency of the information behind it.

Below, we summarise the main blocks of information that should be identified in order to build a useful blueprint:

What is a blueprint used for in practice?

The blueprint eliminates structural errors in planning. It is common to find models where internal transfers are treated as sales, returns are not subtracted correctly or purchases are confused with actual consumption. These errors, often invisible at first glance, distort forecasts and lead to unreliable stock decisions. Explicitly defining which movements generate demand and which generate supply prevents these problems at source.

Another key aspect is that the blueprint helps to correctly define demand per centre, which is especially critical in networks with a central warehouse and branches. In these environments, demand from the central warehouse is not limited to direct sales, but also includes replenishment of satellite centres. Without this distinction, the central warehouse often appears oversized and the branches underutilised, when in reality the problem lies in how consumption is measured.

This diagram represents a typical logistics blueprint with a central warehouse, shops and customers, illustrating which movements generate demand and which do not.

The central warehouse is supplied by suppliers. This flow adds stock, but it is not demand, it is supply. The warehouse replenishes stores that consume their inventory, but this is not real demand.

The shops sell to end customers, and these sales constitute the most visible demand in the system. When a customer returns a product, demand is reduced as the stock re-enters the network.

The blueprint also includes other common movements, such as returns from stores to the warehouse or transfers between stores. These flows do not represent overall demand, although they do affect the stock levels at each specific point.

The key to the diagram is to distinguish between:

- Movements that consume stock and generate demand.

- Movements that replenish stock or adjust inventory without being demand.

Thanks to this differentiation, the blueprint makes it possible to identify where demand is actually generated and avoid common mistakes when planning inventory in multi-level networks.

Blueprint: A basic element for supply chain planning

Creating the blueprint is one of the first actions we take when starting a project at Slimstock. Before talking about forecasting, stock levels or service, we need to understand how demand and supply actually flow within the organisation. This map allows us to align all teams on the same operational reality, eliminate misinterpretations and build planning models that are consistent with the actual functioning of the logistics network.