Table of contents

Table of contents- Empower Your Purchasing Team to Drive Supply Chain Excellence

- The importance of the purchasing department

- Value creation through procurement

- The procurement department’s roadmap

- Developments in coordination with suppliers and the purchasing department

- Supplier evaluation

- Conclusion: The purchasing function: a lever of efficiency and innovation for organisations

- Frequently Asked Questions (FAQs)

Overview

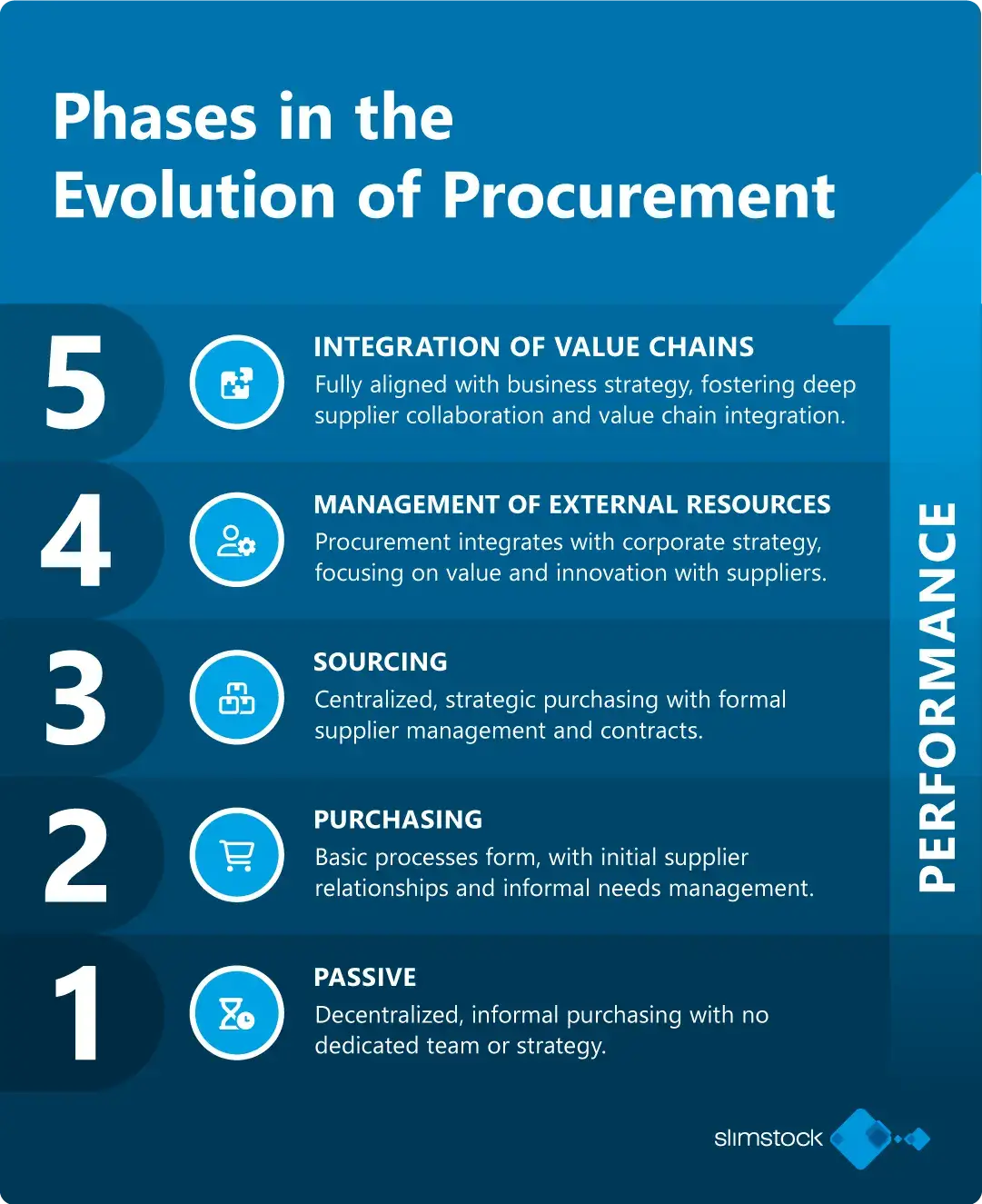

The purchasing department has evolved from a mere operational function to a strategic lever for efficiency and innovation, with procurement costs averaging 60% of total sales. Its roadmap includes five phases, moving from a passive, unorganised approach to full integration of value chains, focusing on cost reduction, quality management, supplier development and co-innovation to strengthen the overall supply chain.

“A chain is only as strong as its weakest link.”

This is a statement often used in the supply chain sector, which is very true, even if somewhat cliché. If we think of the supply chain in an extremely simplified way, it would be made up of three elements: our supplier, our company and the customer.

The reality, however, is infinitely more complex. Our suppliers can number tens or even hundreds and in turn are also dependent on their suppliers, not to mention the fact that very often there are logistics service companies acting as intermediaries.

All the steps that take place before the product arrives at our company (known as upstream management) will be the responsibility of the purchasing department, which in turn will define the purchasing strategy.

The importance of the purchasing department

Purchasing plays a very important role in the activity of a company, especially if we take into account its weight in the accounts of most organisations.

Financial impact of procurement

On average – although taking into account that each case is different – purchasing is considered to account for 60% of the total sales volume in companies. This means that any improvement in purchasing efficiency has a direct impact on margin and thus profitability.

The purchasing department is responsible for managing large volumes of expenditure and investment, which directly affects operating costs. Reducing procurement costs not only improves margins, but can also free up capital that can be reinvested in other strategic areas such as research and development, market expansion, or equipment and technology improvements.

The strategic role of procurement

Beyond trying to reduce costs, the role of the procurement department has evolved from a purely administrative function to one with a strategic component. Today, procurement professionals not only focus on getting better prices and procurement conditions but also play a key role in innovation, sustainability and risk management.

This evolution has been made possible by a more analytical approach and the adoption of advanced technologies that enable better decision-making.

Alignment of procurement with corporate strategy

For purchasing to contribute effectively to business success, it must be aligned with corporate strategy. This implies that purchasing decisions should be linked to the company’s overall objectives, such as entering new markets, improving product quality, and establishing improved service levels or sustainability goals.

Value creation through procurement

Value creation in procurement goes beyond simple cost reduction. It involves innovation, quality management, supplier development and supply chain optimisation to generate a positive impact on the business in the long term.

Innovation in procurement

Innovation is key to creating value. Purchasing can drive innovation by working closely with suppliers to develop new products, improve existing products or implement processes that are more efficient. This collaboration can result in items with better margins, more efficient processes and higher customer satisfaction.

Quality management

Maintaining high-quality standards is essential to the success of any business. In purchasing, quality management involves selecting suppliers that meet established standards, implementing quality controls in the procurement process, and continuously monitoring the performance of the supplier and its products.

Supplier development

Supplier development is a strategy that focuses on improving the capacity and efficiency of existing suppliers. This may involve training, investment in technology, or even strategic alliances that strengthen the relationship and improve the competitiveness of both partners.

Supplier development not only helps to ensure quality and supply but can also open up opportunities for joint innovation and access to new markets.

Supply chain optimisation

Supply chain optimisation is another area where procurement can create significant value. This includes efficient inventory management, reducing lead times and improving coordination between the different actors in the chain. An optimised supply chain can reduce costs, improve customer satisfaction, and increase supply chain resilience.

The procurement department’s roadmap

The evolution of a procurement department’s roadmap reflects a process of maturity and sophistication from a passive and reactive stance to a strategic and proactive force within the organisation.

This path unfolds in five main phases, each characterised by a significant change in the way purchasing and supplier relations are managed:

Phase 1: Passive (Everyone buys)

The purchasing department is little more than a decentralised and unorganised activity:

Strategy

At this early stage, the purchasing strategy is practically non-existent. The internal needs of the company are not clear and the supplier market is completely unknown. There is no strategic approach to managing purchasing.

People

There is no formal purchasing department. Instead, all employees are in charge of the procurement of their required goods without any specific training, buying what they need without coordination or centralised support.

Processes

There is no grouping of purchasing volumes or standardised processes. The company has no indicators or performance measurement system in purchasing, which leads to a lack of control and very low optimisation.

Suppliers

As for the suppliers, they are the ones who manage the relationship. There are no formal contracts, only orders and invoices and no supplier panel management. The company simply pays for the products without further consideration.

Communication

Communication is non-existent at this stage. There is no internal or external coordination, reflecting the lack of integration and management in the procurement area.

Phase 2: Purchasing

This is where the purchasing department starts to take shape and the first formal processes are established:

Strategy

The strategy is based on day-to-day departmental action, although it remains informal. Internal needs are better understood, but knowledge of the supplier market remains limited.

People

A purchasing department is defined, although it is at the most basic level. Skills are mainly focused on transaction management, such as dealing with orders and invoices. Management is collective and there is no focus on individual development.

Processes

Processes begin to take shape. Orders, invoices and claims are managed, and basic policies and processes are implemented. Procurement systems and tools are used, marking a significant step forward.

Suppliers

Supplier relationships are more formal, with a defined supplier panel. Purchasing initiates relationships and begins to evaluate key suppliers, although the relationship remains simple.

Communication

Communication improves within the department, with a focus on measuring transactions. However, it remains internal and does not extend to other stakeholders.

Phase 3: Sourcing

The purchasing department takes a step forward, adopting a more strategic and market-oriented approach:

Strategy

The strategy is formalised and centralised in the purchasing department. Internal needs are well known and the supplier market is better understood, allowing for more proactive management.

People

The department is organised around specific categories and suppliers. Negotiations and framework contracts become more common, and both collective and individual management are strengthened.

Processes

Business practices become more sophisticated. Large RFXs are managed, and the supplier panel is optimised. The department leads productivity actions and starts to manage quality more actively.

Suppliers

Relations with suppliers become more cooperative. Contracts are formalised and panels are optimised, allowing for a more balanced and collaborative relationship between the company and its suppliers.

Communication

Communication is extended to suppliers and supplier performance is measured, facilitating better decision-making and greater transparency in relationships.

Phase 4: Management of external resources

In this phase, the purchasing department is deeply integrated into the company’s strategy:

Strategy

Purchasing actively participates in defining the company’s strategy, ensuring that strategic product families are aligned with corporate objectives. The strategy is developed together with top management, which underlines the importance of the department.

People

The purchasing department is part of the steering committee, intervening in key decisions. It is managed in conjunction with senior management, and the focus is on value creation through supplier management and innovation capture.

Processes

Business practices are geared towards protecting and optimising the entire supply chain. It involves contracts that protect the company and align strategies with suppliers, encouraging continuous improvement.

Suppliers

Top management is involved in the selection of strategic suppliers. The relationship with suppliers is based on co-management and collaboration for mutual development and innovation.

Communication

Communication is broadened to include top management, shareholders and other stakeholders. The company’s communication strategy now integrates procurement, reflecting its strategic importance.

Phase 5: Integration of value chains

The final phase of the roadmap is where the purchasing department reaches its highest level of integration and maturity:

Strategy

At this point, purchasing not only supports but also drives the business strategy. Value chains overlap and integrate, enabling full cooperation within and outside of the company.

People

The purchasing department is fully integrated into the company’s management and plays an important role in defining and executing corporate strategy. Control is shared with top management, which facilitates agile and effective decision-making.

Processes

Processes reach their highest level of development. The entire value chain is managed with a focus on continuous improvement and co-management with key suppliers, ensuring that the entire company is aligned in value creation.

Suppliers

Relations with suppliers are based on strategic collaboration, seeking long-term benefits. Integration with suppliers is total, allowing the company to adapt quickly to market demands while simultaneously fostering innovation.

Communication

Communication extends to all levels, including all relevant stakeholders. Transparency and collaboration are key at this stage, ensuring that all parties are aligned with the company’s objectives.

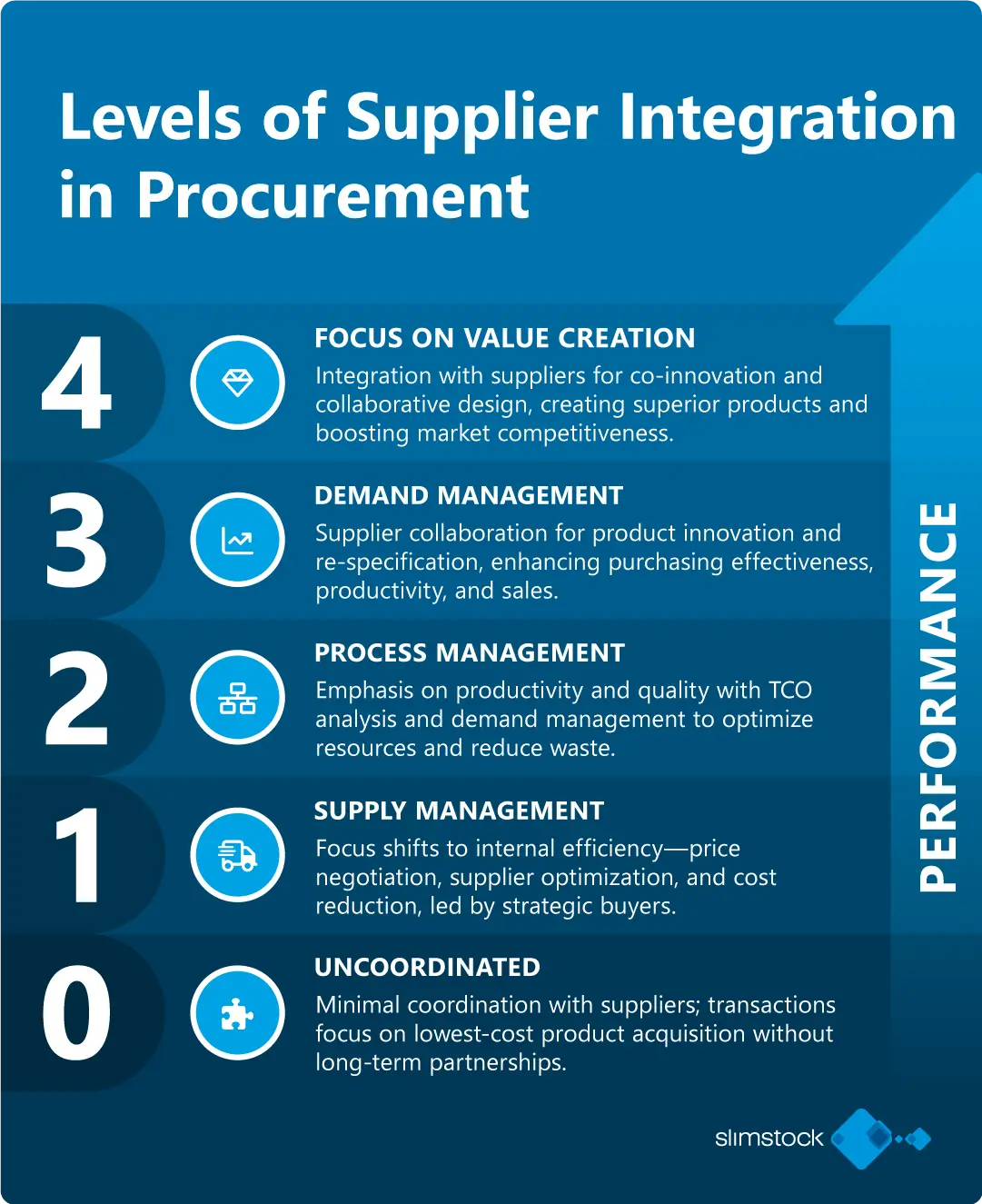

Developments in coordination with suppliers and the purchasing department

As shown in the previous point, managing and collaborating with suppliers is one of the main tasks of procurement teams. The relationship between a company and its supply chain partners progresses through several levels of integration, each with its own approach and methods to improve efficiency and generate value:

Level 0: Uncoordinated

At this level, there is no significant coordination with suppliers. Purchasing is focused on basic transaction execution, and buyers operate tactically and locally. The priority is to procure products at the lowest cost without considering optimisations or long-term partnerships.

Level 1: Supply management

Here, the focus becomes more internal, with an emphasis on process integration. Activities include price negotiation, volume consolidation, and supplier rationalisation. Strategic buyers begin to lead processes, improving internal efficiency and reducing costs.

Level 2: Process management

At this level, the company focuses on productivity through process management, quality optimisation and total cost of ownership (TCO) analysis. Demand management is also introduced, seeking to optimise quantities and reduce waste, which allows for better resource management.

Level 3: Demand management

The focus broadens and collaboration with suppliers on product re-specification and innovation begins, seeking not only to buy better but also to improve productivity and sales.

Level 4: Focus on value creation

At the most advanced level, integration with suppliers focuses on value creation through co-innovation and collaborative design. The company and its suppliers work together to generate products and services that offer superior value, driving competitiveness and innovation in the marketplace.

Supplier evaluation

The purchasing department works in close cooperation with suppliers, hence the success of the purchasing strategy depends to a large extent on the performance of these ‘partners’ in the supply chain. This is why it is important to monitor the performance of our partners.

So how can we measure the value of a supplier? We propose that you ask yourself the following questions:

What percentage of total category expenditure does this supplier represent?

It is important to understand how significant the spending with one supplier is compared to the category total. A high percentage could indicate a key relationship, which merits more strategic management.

What are the savings and productivity potential with this supplier?

Assess whether the supplier offers opportunities to reduce costs or improve productivity. This may include better prices, more flexible payment terms or innovations that optimise the production process.

Do customers perceive the value of this supplier?

Consider whether the supplier contributes significantly to the differentiation of the final product that reaches the customer, thus enhancing the customer’s perception of value, which is a strategic asset.

Does this provider allow access to state-of-the-art technology or innovations?

Suppliers that introduce new technologies or innovations can offer a significant competitive advantage, keeping the company at the forefront of the market.

How would a failure or outage of this supplier affect customer satisfaction?

Analyse the potential impact of a supply failure. If an outage could seriously affect customer satisfaction, this supplier should be managed with special attention.

What is the total impact of this supplier on the category?

Finally, consider the overall impact of the supplier on the category. A supplier that has a high impact in several key areas is critical to the success of the company and should be treated as such.

Conclusion: The purchasing function: a lever of efficiency and innovation for organisations

As shown in this article, the purchasing department has evolved from a merely operational function to become a strategic role player within organisations. The great weight of procurement in company budgets makes the purchasing department a fundamental link in terms of cost adjustment. It even plays a determining role in innovation in companies through collaboration with suppliers and customers.

At the same time, the effectiveness of the supply chain also relies on a well-oiled purchasing process and close cooperation with the other links in the supply chain. Therefore, the efficiency of an organisation’s supply chain and its ability to generate added value depends to a large extent on the well-oiled functioning of the purchasing department.

Ready to transform your purchasing strategy? See how Open to Buy Software by Slimstock can help you gain full control over your purchasing budget and streamline your supply chain

Frequently Asked Questions (FAQs)

Why is it important to align procurement with corporate strategy?

Aligning procurement with corporate strategy ensures that procurement decisions contribute directly to business objectives such as market expansion, product improvement and sustainability. This maximises the value generated and optimises the financial impact on the company.

How can the purchasing department contribute to innovation?

Purchasing can drive innovation by working closely with suppliers to develop new

products and improve processes. This cooperation improves efficiency and leads to more competitive products and higher levels of customer satisfaction.

What is the role of the purchasing department in risk management?

Procurement plays a key role in risk management by selecting and evaluating suppliers that meet quality and sustainability standards. It also manages contracts that protect the company against supply disruptions, ensuring the resilience of the supply chain.

What does it mean to optimise the supply chain from the purchasing department?

Optimising the supply chain means managing inventories efficiently, reducing lead times and improving coordination between all actors involved. A focus on optimisation helps to reduce costs, increase customer satisfaction and strengthen business resilience.

How is supplier performance measured by the purchasing department?

Supplier performance is measured through indicators such as product quality, on-time delivery and innovation. Evaluating suppliers on an ongoing basis allows the purchasing department to ensure that they contribute positively to the value chain and business success.