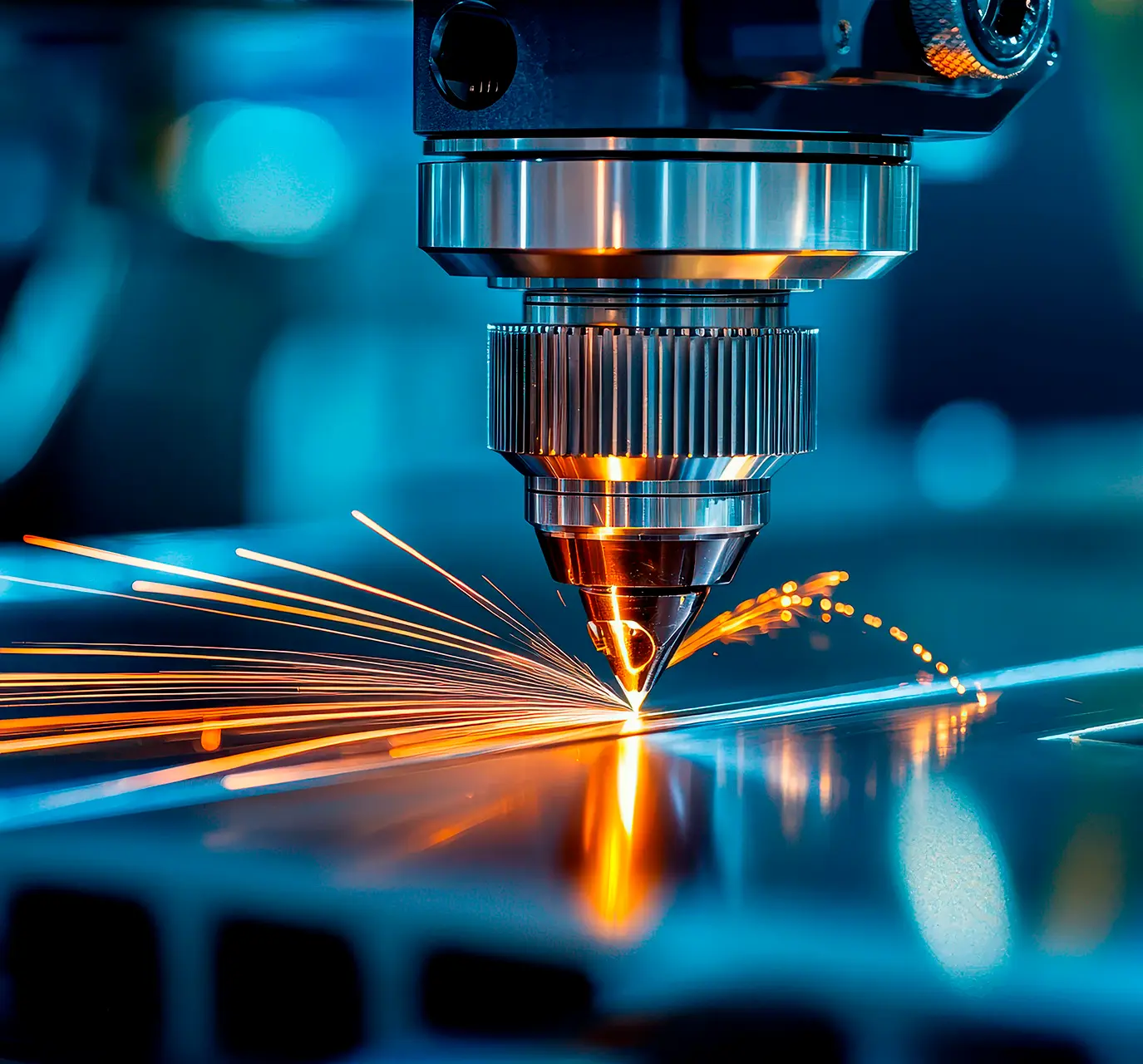

Manufacturing

Connect long-term forecasts with daily, optimised execution

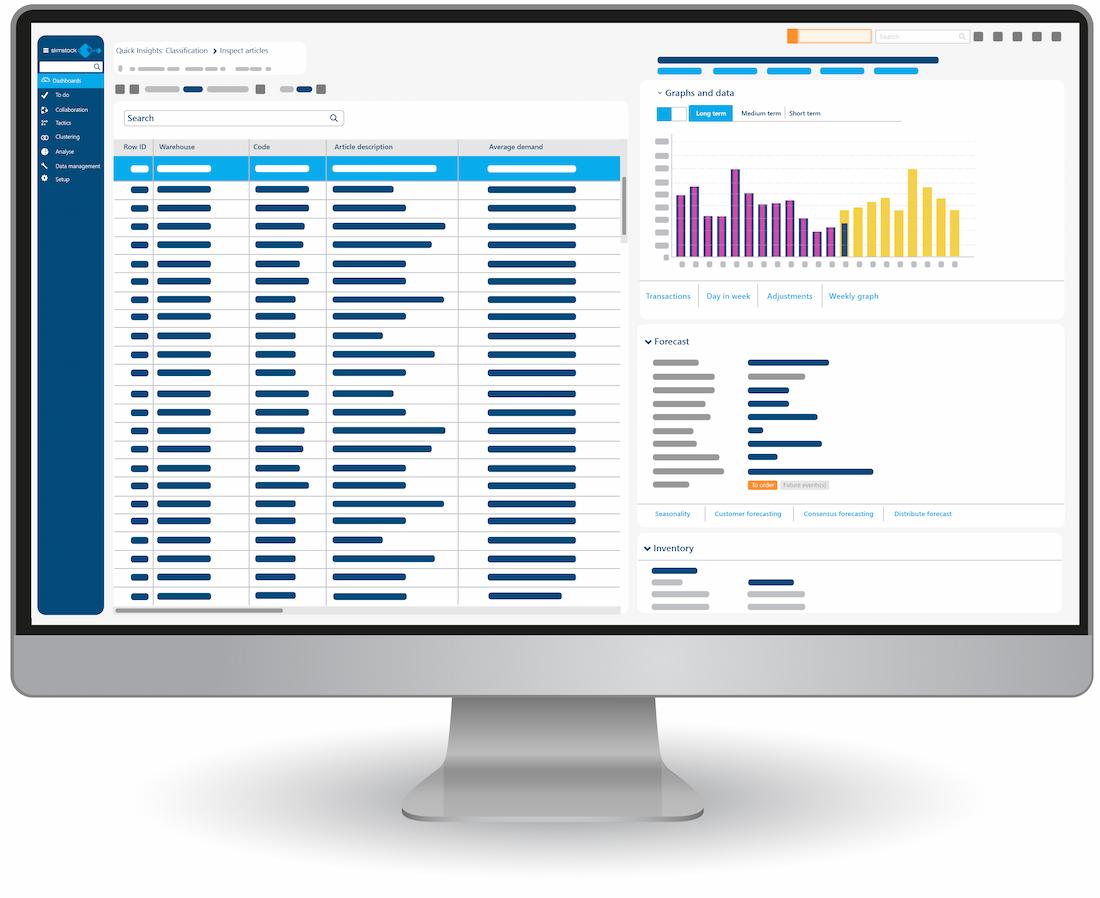

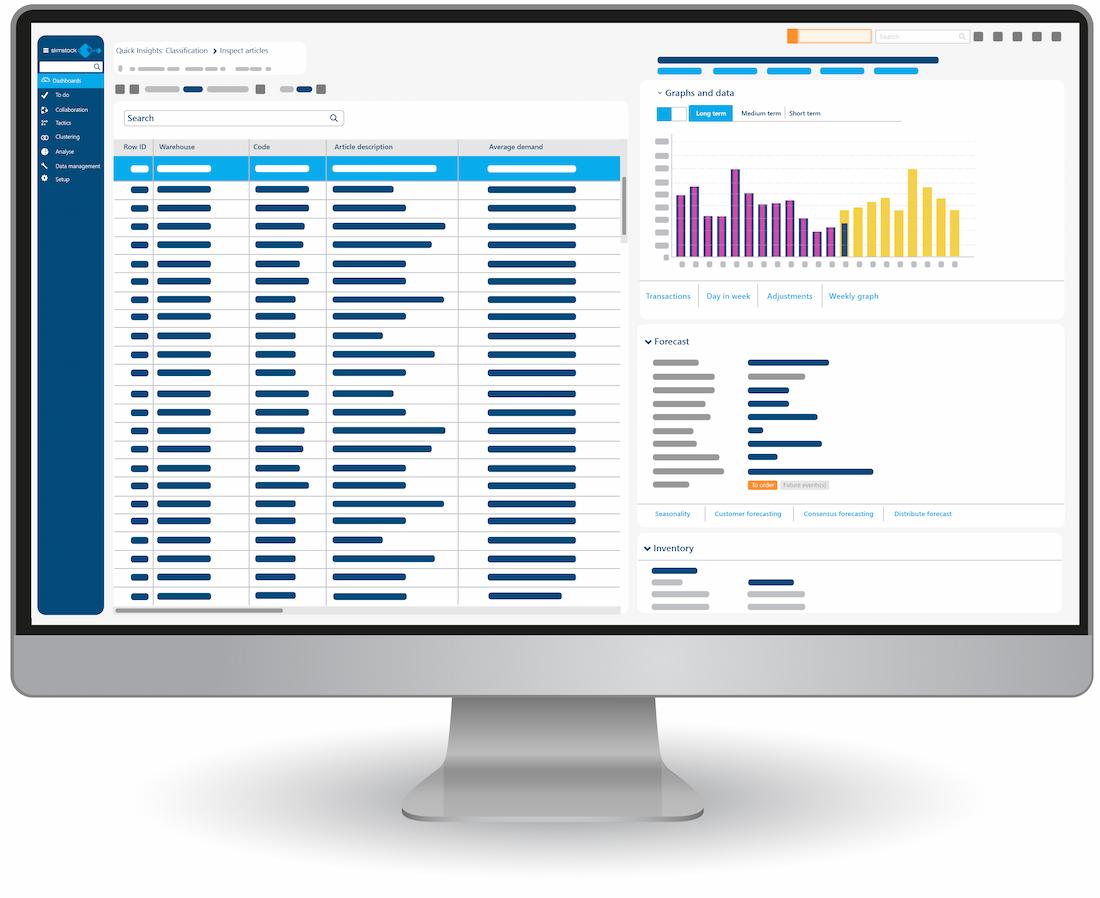

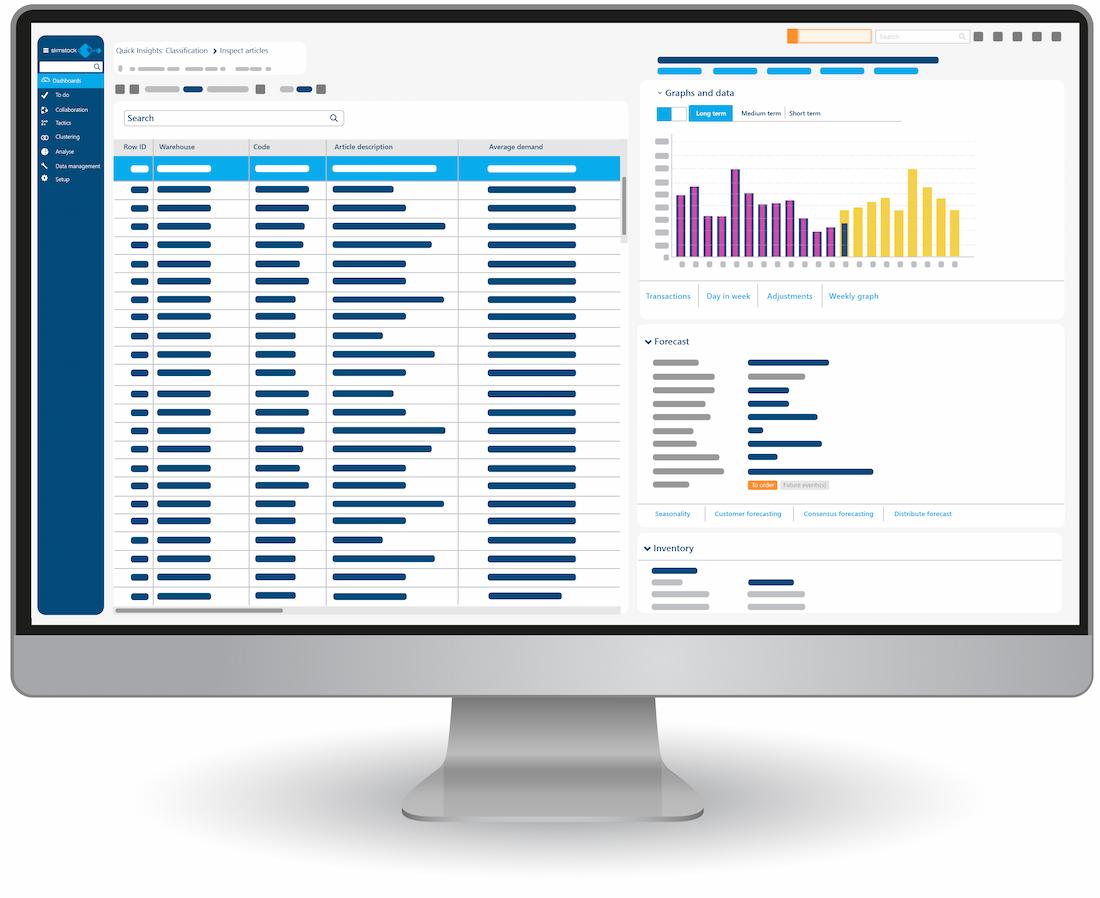

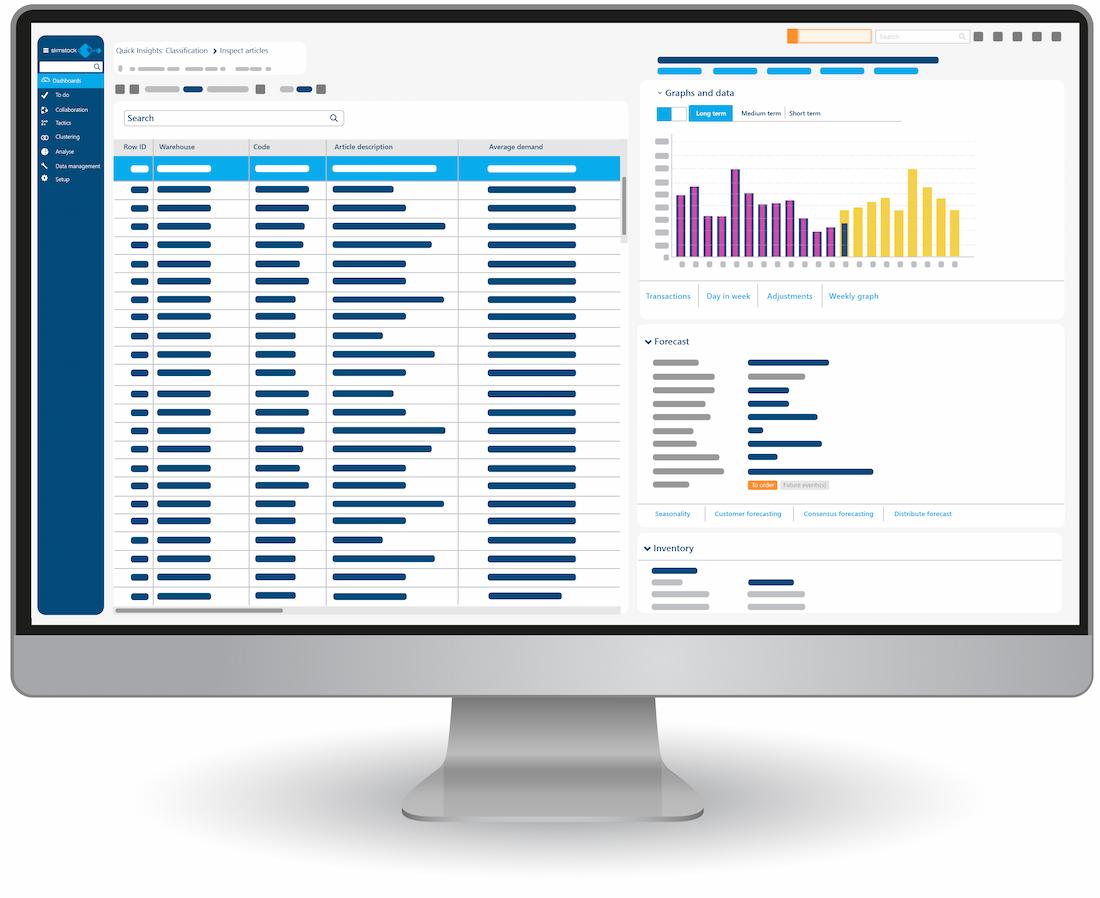

Slimstock’s Slim4 platform eliminates reliance on spreadsheets, stabilises production forecasts, and allows you to optimise resources based on a continuous, clear plan of action.

Slim4’s key features for manufacturing

Slimstock’s holistic platform provides powerful, industry-specific tools to transform supply chain planning and execution in the manufacturing sector.

Forecast aggregation and comparison

Improve service levels and reduce the need for urgent replanning by establishing optimal plans based on clear forecasts, while also staying agile to any sudden demand or capacity shifts.

Improved visibility into planning gaps and decision-making is enabled by the Slim4 platform, allowing for a more precise long-term outlook that can be filtered into the short term production process.

Component availability and sourcing

By moving away from spreadsheets and legacy tech you can procure with precision, based on exact forecasts. Both cost- and production-efficiency is achieved by aligning real-time availability with production requirements.

With clarity around what’s needed and what’s possible, Slim4 enables you to prioritise with data-driven confidence. This allows you to handle volatility through flexible recalculations, and to fulfil promises with customers.

Avoid a disconnect between S&OP and daily planning by integrating business intelligence into your architecture. With greater visibility, you can communicate more clearly across departments for smoother workflows.

Slim4’s holistic, end-to-end capabilities filter into the scheduling process, leading to optimised workload distribution across machinery and operations.

Kick Start Your S&OP in 90 Days

Launch a result-driven S&OP process in just one quarter. Simple, focused and proven

Download

Find out how you

can

See Slim4 in action

From our customers to you

Game-changer for our Supply Chain performance.

Once we had decided on which Supply Chain planning software you implement, it was a relatively straightforward implementation. We had great support from the Slimstock implementation team throughout the whole process.

Slim4 has helped us centralize our purchasing, which has led to less time spent overall when it comes to purchasing.

At the same time we have increased our service levels to customers by several percentage points while keeping our stock levels low.

Slim4 was an easy tool to learn with an intuitive interface.

The team was quite hands-on in getting the implementation done as efficiently as possible and the results were quite evident from the get-go.

Speak to one of our experts

Book a 1-2-1 demo