Overview

Effective stock allocation, supported by close supply chain collaboration and real-time data sharing, allows businesses to quickly adjust inventory during unexpected demand spikes (e.g., local emergencies). This responsiveness builds resilience, prevents stockouts, reduces waste and improves customer satisfaction.

Supermarkets and wholesalers constantly juggle the challenge of keeping shelves stocked while avoiding excess inventory. Striking the right balance between maintaining service levels and managing stock efficiently takes a structured yet flexible approach.

Sometimes, demand for a product can skyrocket out of nowhere, making strong collaboration across the supply chain crucial. Without it, the risk of stock shortages rises fast.

A clear example of this happened in October 2024, when bottled water sales surged across parts of the Netherlands after E. coli was found in the tap water.

On a Friday evening, water company Vitens advised around 70,000 households in the Apeldoorn region to boil their tap water before use or stock up on bottled water. The announcement led to an immediate surge in demand, with supermarkets across the area seeing shelves emptied that same night and throughout the weekend. Less than a week later, the Venray region went through a similar situation, forcing supermarkets and food retailers to scramble in order to keep up with demand and continue serving their customers.

Sudden spikes in demand can lead to empty shelves

Speaking to regional newspaper De Stentor, one supermarket revealed that it had suddenly started ordering 10,000 litres of bottled water per day, which meant ten times its usual amount of around 1,000 litres. Meanwhile, demand in other parts of the country remained low.

The water crisis in Apeldoorn and Venray is a prime example of how a local spike in demand can create major imbalances in the stock planning of national supermarket chains. While bottled water flew off the shelves in Apeldoorn and surrounding areas, stores in the Randstad remained fully stocked, with far less demand. A more responsive and flexible allocation of stock could have eased the pressure, not just in the short term but in the long run as well.

Better allocation helps supermarkets prevent shortages while avoiding excess stock, reducing waste, storage costs and inefficiencies. And ultimately, if a shop runs out of key products, customers will go elsewhere. There’s no guarantee they’ll return. In short, effective stock allocation is vital for the continuity of any business.

What is allocation?

In the context of the supply chain, allocation refers to the process of distributing resources, products or inventory in the most effective way to meet demand. The aim is to ensure that the right products are available at the right time and place while minimising wasted time, money and resources.

Allocation can take different forms within the supply chain:

- Inventory allocation: distributing available stock across customers, distribution centres or stores based on demand, availability and priority.

- Capacity allocation: assigning production resources such as machinery, labour or warehouse space to specific production lines or tasks.

- Transportation allocation: managing transport resources to move products efficiently, taking into account elements such as cost, distance and delivery time.

Allocation is about executing strategic decisions to prevent bottlenecks and improve the overall efficiency of the supply chain.

Flexible response can only be achieved through close cooperation

The practical example of Apeldoorn and Venray is a typical example of stock allocation, and this problem is not an isolated one.

Increasingly, supermarkets are flooded with unexpected demand. A few weeks earlier, the same bacteria caused the same problem in the Zevenaar region, but the “hoarding” for toilet paper in the early stages of the corona pandemic will also be familiar to many.

So responding to the right data daily to push your stock to the right stores based on actual sales is of real importance. Close collaboration in the chain is essential and indispensable here.

Suppose Vitens had informed the supermarkets in the Apeldoorn area on Friday afternoon about the imminent problem, the demand planners could allocate stock as early as Friday afternoon in order to have enough stock of water bottles on Saturday. In other words, close collaboration in the supply chain increases the efficiency, agility and profitability of companies.

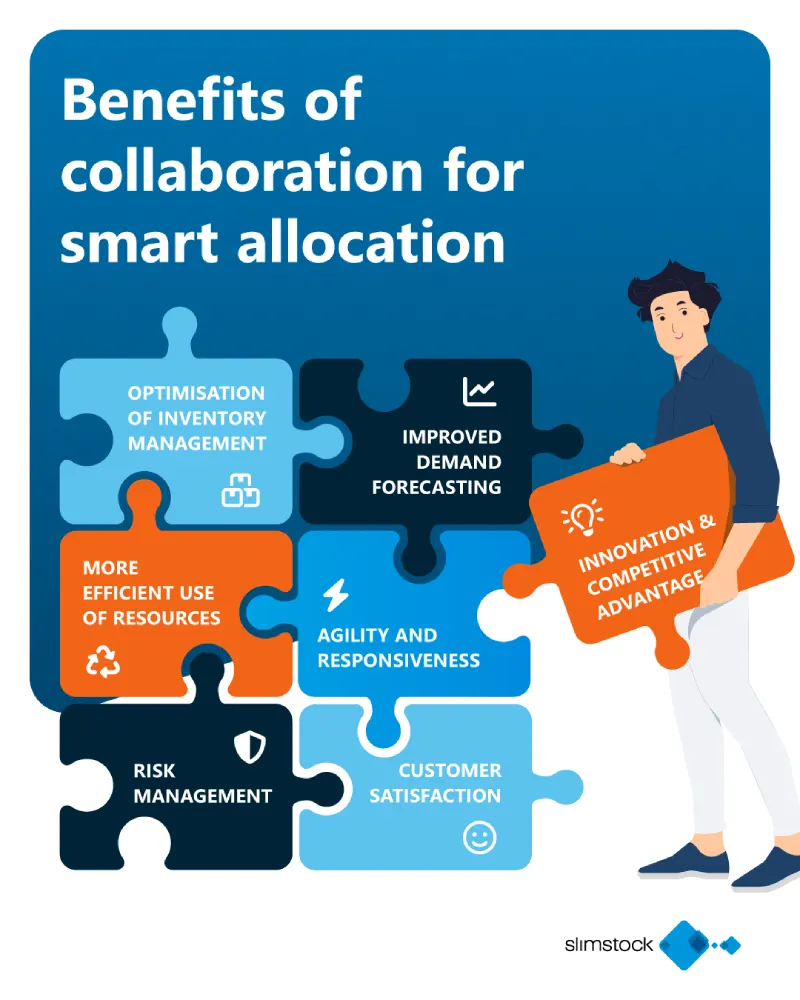

Benefits of collaboration for smart allocation

The smart allocation of resources, such as raw materials, labor and production capacity, requires that different links in the chain work well together to ensure that the right products are available at the right time and at the right cost.

Here are some of the key benefits of collaborative allocation in the supply chain:

Optimisation of inventory management

Good collaboration between suppliers, manufacturers, distributors and retailers ensures that inventory levels are managed optimally. This reduces overproduction, inventory shortages and waste.

For example, by sharing real-time information on demand forecasts and inventories, companies can respond quickly to changes in the market and avoid overstocking or understocking.

Improved demand forecasting

Collaboration improves demand data sharing, which increases the accuracy of demand forecasts. For example, when retailers share their sales data with suppliers and manufacturers, they can better match their production capacity to actual demand, leading to fewer surpluses and shortages.

More efficient use of resources

By working together, companies can make better use of resources like transportation, warehousing and production capacity. This not only cuts costs but also improves efficiency. For example, combining shipments helps prevent empty trips, reducing expenses and lowering the overall carbon footprint.

Agility and responsiveness

A flexible supply chain is key to handling disruptions, whether they come from shifting demand, supply shortages or economic changes. By sharing information and coordinating plans, businesses can react quickly and adjust stock distribution to stay ahead of challenges.

Risk management

Collaboration strengthens risk management across the supply chain. Open communication about potential bottlenecks in production or delivery allows companies to take early action, whether that means reallocating raw materials or adjusting production schedules to avoid disruptions.

Customer satisfaction

Effective stock management through collaboration ensures customers get what they need, when they need it and at the right price. This not only prevents shortages but also helps maintain high levels of customer satisfaction.

Innovation and competitive advantage

Cooperating in resource allocation can help companies introduce innovations more quickly. By working together in research, development and production, businesses can bring new solutions to market faster. Companies that streamline and adapt their supply chains gain a competitive edge, which enables them to respond more effectively to market opportunities.

Conclusions

Effective collaboration in the supply chain ensures quicker and more accurate stock allocation, reducing risks and boosting customer satisfaction. It helps create a more adaptable, resilient and future-ready supply chain that can respond to market shifts and operational challenges. By working together, businesses can make the most of their resources, build a more sustainable model and improve profitability. To support these efforts, many retailers rely on inventory allocation solutions like the one from Slimstock, which help ensure stock is distributed efficiently and aligned with actual demand.