Table of contents

Table of contents- Return On Investment (ROI): what it means, how to calculate it and why it matters in the supply chain

- What is Return On Investment (ROI)?

- Why ROI matters and how to use it in the supply chain?

- How to calculate ROI

- Identifying costs and gains in supply chain projects

- Examples of ROI calculation

- What does a good ROI mean?

- How do I measure the ROI of my supply chain project?

- Advantages of working with ROI in business strategy

- ROI and Slimstock: Achieving measurable results

- FAQs about ROI (Return On Investment)

Overview

Return on Investment (ROI) is a key measure of profitability that quantifies the profit or loss from an investment relative to its cost. It is calculated as: ROI = [($ ext{Gain} – ext{Cost}) / ext{Cost}] imes 100$. In supply chain management, ROI is crucial for making informed decisions, tracking performance over time and prioritizing initiatives—such as new software or process improvements—that lead to measurable benefits like reduced costs, higher sales and improved service levels.

Every investment involves a degree of uncertainty and risk. When a company decides to commit resources, whether time, money or effort, it’s only natural to ask: what’s the return going to be? This is where ROI, or Return on Investment, becomes essential.

In this article, we’ll explore what ROI means, how to calculate it and why understanding this indicator is so important for supply chain success.

What is Return On Investment (ROI)?

At its core, Return on Investment (ROI) is a measure of profitability. It tells you how much profit or loss a company makes from an investment relative to its cost.

The formula is applicable to almost any type of business initiative: marketing campaigns, process improvements, new software implementations, infrastructure upgrades or customer service projects. If you can attach a cost and a measurable return to an action, you can measure its ROI.

In supply chain management, ROI is particularly useful because supply chains involve multiple processes such as buying a new warehouse, implementing a new demand planning tool or even rolling out a new range of products. ROI helps quantify the impact of improvements across these functions, for example:

- How much time and money could be saved by automating demand forecasting?

- What financial gain results from investing in a new warehouse management system?

- Is a new supplier collaboration programme delivering value?

By measuring ROI, businesses gain a clearer picture of which initiatives are truly driving performance and which are not. It helps prioritise investments that contribute to long-term efficiency and profitability.

Why ROI matters and how to use it in the supply chain?

Understanding ROI helps supply chain leaders align operational initiatives with business goals.

Making informed, confident decisions

When businesses understand the ROI of their projects, they can make more informed decisions about where to allocate resources. Instead of relying on assumptions, leaders can back their strategies with data. This increases confidence in decision-making and helps justify investments to stakeholders.

Tracking performance over time

ROI also provides a benchmark for measuring performance. By comparing returns from past initiatives, companies can set realistic goals and continuously refine their strategies. This ensures that every pound invested contributes to measurable improvements such as reduced costs, improved service levels or faster lead times.

Driving continuous improvement

Another important benefit of ROI is that it promotes a culture of continuous improvement. Teams that monitor ROI regularly are more likely to identify inefficiencies, test new ideas and focus on long-term results. In supply chain management, where change is constant, this mindset is essential.

Real-world relevance

Take logistics, for instance. When you track ROI, you might spot one carrier that keeps costs down and shows up on time, every time. In procurement, digging into ROI sometimes shows that consolidating suppliers actually cuts down on all that extra paperwork. Across all areas of the supply chain, ROI acts as a reality check to ensure resources are generating the right level of value.

How to calculate ROI

Calculating Return on Investment is pretty simple, yet it provides powerful insights. The formula is: ROI = [(benefit – costs) / costs] x 100

Where:

- Gain from Investment refers to the total financial return or profit generated by the investment.

- Cost of Investment represents the total expenditure required to implement it.

The result is expressed as a percentage, making it easy to compare across different projects or strategies.

For example, an ROI of 50% means that for every £1 invested, the business earned £1.50 in return (a £0.50 profit).

Identifying costs and gains in supply chain projects

When applying ROI in a supply chain context, it’s important to identify all relevant costs and gains accurately.

Costs may include:

- Software licences and implementation fees

- Hardware and equipment purchases

- Training and change management expenses

- Labour and administrative costs

- Logistics, inventory and storage costs

- Financial costs such as interest or insurance

Gains may include:

- Higher sales through improved product availability

- Lower transportation and purchasing costs

- Reduced waste or obsolescence

- Increased productivity through automation

- Shorter lead times and better service levels

By mapping these elements clearly, you can ensure your ROI calculation reflects the full picture.

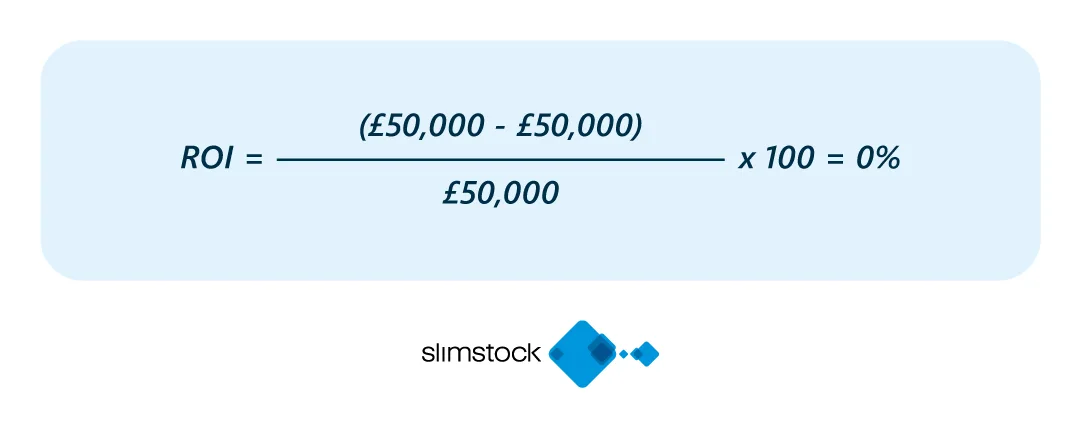

Examples of ROI calculation

Let’s imagine your company invests £50,000 in a new inventory optimisation tool. After one year, the system reduces excess stock and improves availability, saving £30,000 in logistics and storage costs and generating £20,000 in additional sales.

Total gain = £50,000

Total cost = £50,000

At first glance, this might seem like a neutral return. However, this figure doesn’t reflect the long-term gains that will continue generating savings over time, such as improved forecast accuracy and reduced workload.

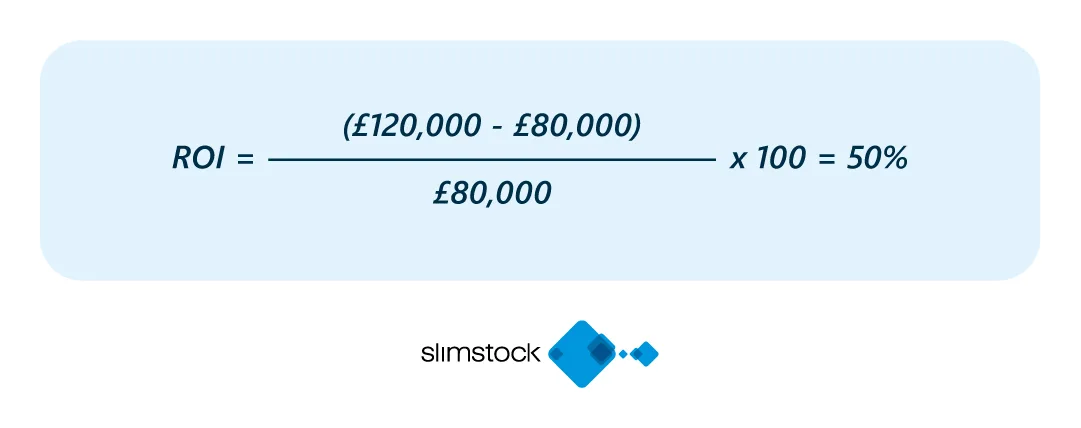

Now, let’s take another scenario. Suppose a supply chain automation project costs £80,000, but delivers £120,000 in annual savings.

This means the project delivers a 50% return in just one year, a strong indicator of value.

What does a good ROI mean?

There’s no single rule for what counts as a “good” ROI. It really depends on your industry, how much risk you’re taking and your timeline. Still, in supply chain projects, people usually see a return above 20–30% in the first year as a good sign.

But let’s be real, numbers aren’t the whole story. You can hit a high ROI on a one-off project, but that doesn’t mean it’ll last. Sometimes a smaller, steady return from a long-term effort ends up being worth more in the long run.

Besides ROI, companies should consider the payback period: how long it takes to recover the initial investment. A project with a moderate ROI but a short payback time might be more attractive than one with higher returns that take years to realise.

How do I measure the ROI of my supply chain project?

ROI calculations often overlook the less quantifiable outcomes that still add value. It is important to consider both tangible and intangible elements when assessing the ROI of a supply chain initiative.

Over time, these benefits translate into cost savings, efficiency gains and higher customer satisfaction, all of which strengthen ROI.

Advantages of working with ROI in business strategy

1. Eliminating unnecessary expenses

Analysing ROI reveals which initiatives truly add value and which simply drain resources. By identifying low-performing activities, companies can eliminate unnecessary costs and redirect funds to projects with higher potential.

2. Increasing profitability

When waste is reduced and investments are more targeted, profitability naturally increases. Optimising ROI ensures every pound spent contributes directly to the company’s bottom line—allowing for reinvestment in innovation and growth.

3. Ensuring long-term stability

ROI analysis isn’t a one-time task; it’s a continuous process. By regularly monitoring ROI, businesses can maintain consistent profitability and adapt quickly to market changes. This approach builds long-term stability rather than short-lived gains.

4. Boosting team confidence and performance

A company that tracks and celebrates its ROI achievements fosters a motivated workforce. Employees who see the results of their efforts feel more engaged and confident, leading to stronger collaboration and higher performance across departments.

ROI and Slimstock: Achieving measurable results

A stock optimisation project can generate significant benefits but it only makes sense when the investment pays back quickly.

That’s why Slimstock only begins a project once it’s clear that the Return on Investment will be achieved within 12 months. This ensures every initiative delivers measurable, sustainable results.

These days, businesses must balance customer satisfaction with optimal inventory costs. Discover how you can align your operations, boost service levels, and achieve real ROI with Slimstock’s Supply Chain Control Tower software.

FAQs about ROI (Return On Investment)

What is ROI and how is it calculated?

ROI measures the profitability of an investment, calculated by dividing the net gain by the cost of the investment and multiplying by 100 to get a percentage

Why is ROI important for business decision-making?

ROI helps businesses assess the efficiency of investments and decide where to allocate resources for maximum profitability.

What are the limitations of ROI?

ROI doesn’t account for time or investment risks, providing an incomplete picture of long-term value