Speak to one of our experts

Book a 1-2-1 demo

Simplify planning, optimise capacity, and gain transparent control

Leverage APS software within a centralised platform to align production decisions with supply and demand metrics.

An AI-powered approach to solving production challenges

Schedule with certainty thanks to the interactive Gantt chart

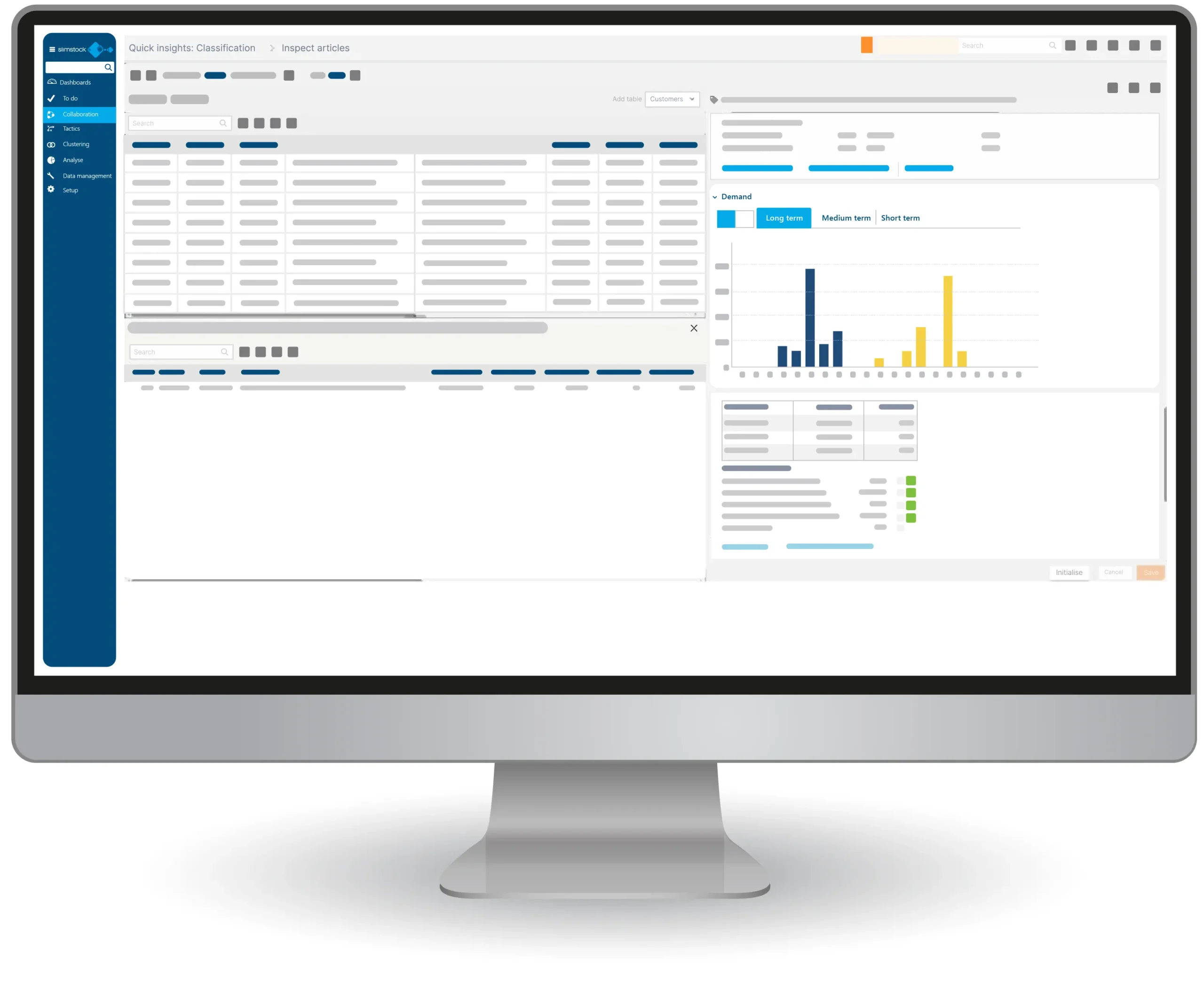

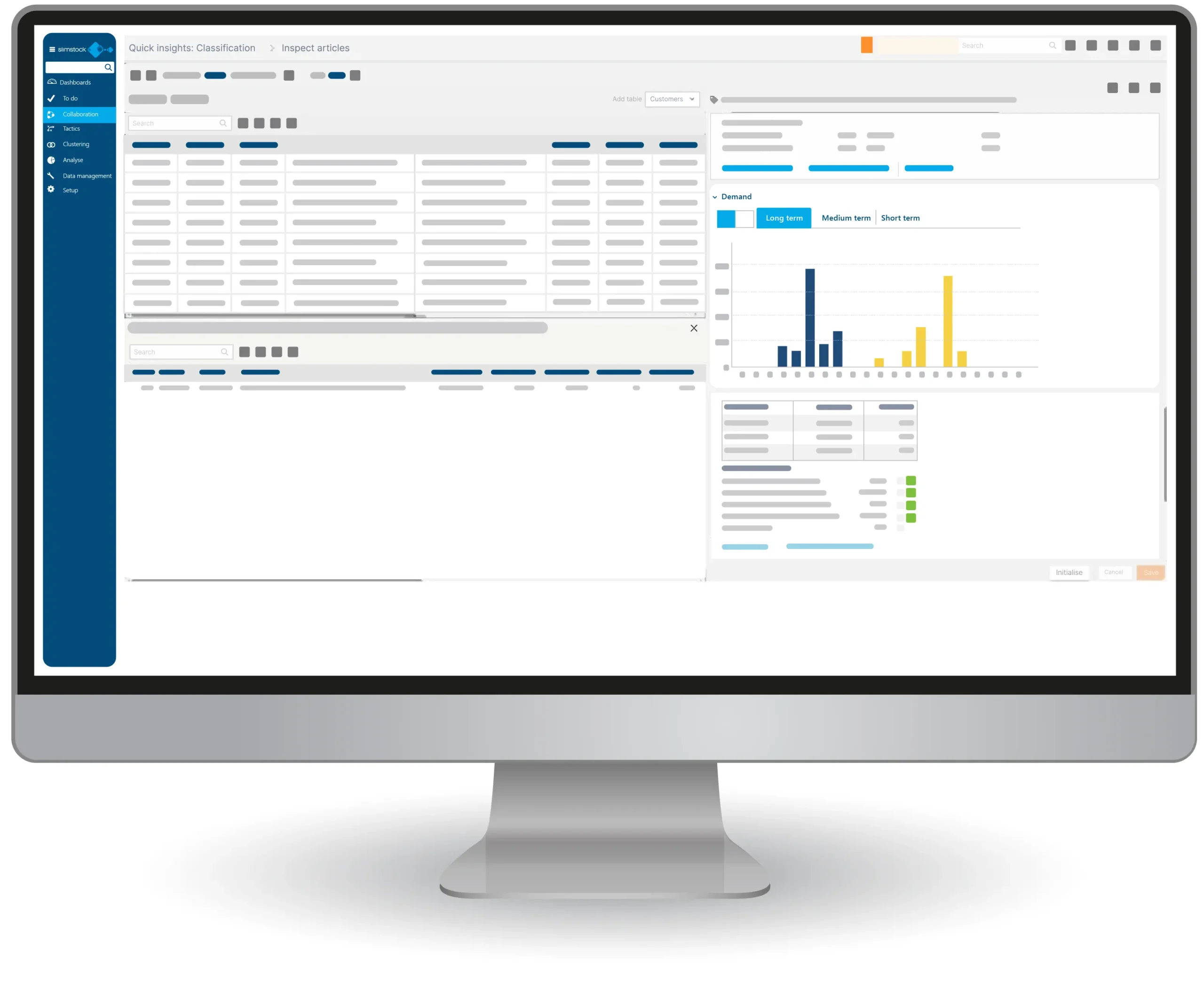

The APS modules’ interactive Gantt chart with drag and drop functionality allows you to quickly visualise your initial production schedule, while remaining agile to any changes in demand, capacity, or priority.

Recalculate production planning in an instant

Automated recalculations ensure that any changes to the schedule are processed instantly, and then reflected through a redetermined schedule. Real-time interfacing integrates orders from the ERP system, as well as updates on tasks from the work floor in real-time.

Optimise each and every production schedule

Slim4’s APS module ensures that any schedule at any time is optimised. The in-built automatic solver processes the full-time picture continuously to always present the best plan of action for your production activities.

The APS module in Slim4 allows you to investigate numerous potential scenarios in a moment, combining those possibilities with a very clear, real-time picture of what’s needed and what’s possible. The ultimate upshot is constant agility, and no wasted time for your business.

Slim4’s interactive Gantt chart is a gamechanger for adaptability and agility. Replacing rigid Excel processes with a configurable, real-time, holistic solution enables your operations to flourish. Changes based on current data are quick, with the consequences of every decision also clearly visible through the platform.

As an inventory management solution, Slim4 is already equipped to connect different functions across the supply chain for complete, end-to-end visibility. The APS module accounts for production planning and scheduling, ensuring those decisions are in tune with your procurement strategy.

Having an APS module already embedded in Slim4 removes the need for a separate APS tool in your IT architecture. Less tools means less maintenance, and more seamless, streamlined integration of data – especially when the platform can also integrate with any existing ERP system.

Production planning software helps schedule and manage production tasks in a clear and structured way. Instead of relying on tools like Excel, it provides a user-friendly environment where plans can be created, adjusted and visualised with ease.

Many manufacturers still plan in spreadsheets, which are hard to maintain and require many manual steps to update. Production planning software offers a clearer overview, quicker replanning and better visibility of the impact of changes, making it easier to handle disruptions on the shop floor.

Advantages os production planning include:

Slim4 offers an APS module built directly into the platform, meaning no separate tool is needed. It includes an interactive Gantt chart, drag-and-drop planning, automatic recalculations, real-time updates from the shop floor and a solver to help create a solid schedule.

The APS module automatically recalculates the schedule whenever changes are made and uses a solver to help planners build a good and feasible plan. It works with live information from the ERP and the shop floor so that decisions are based on the latest data.

Slim4 connects directly with the ERP system in real time. Orders and updates flow automatically between the shop floor and the APS module, ensuring Slim4 is always working with the latest production information. This also reduces the need for extra tools and lowers IT maintenance.

Book a 1-2-1 demo