Table of contents

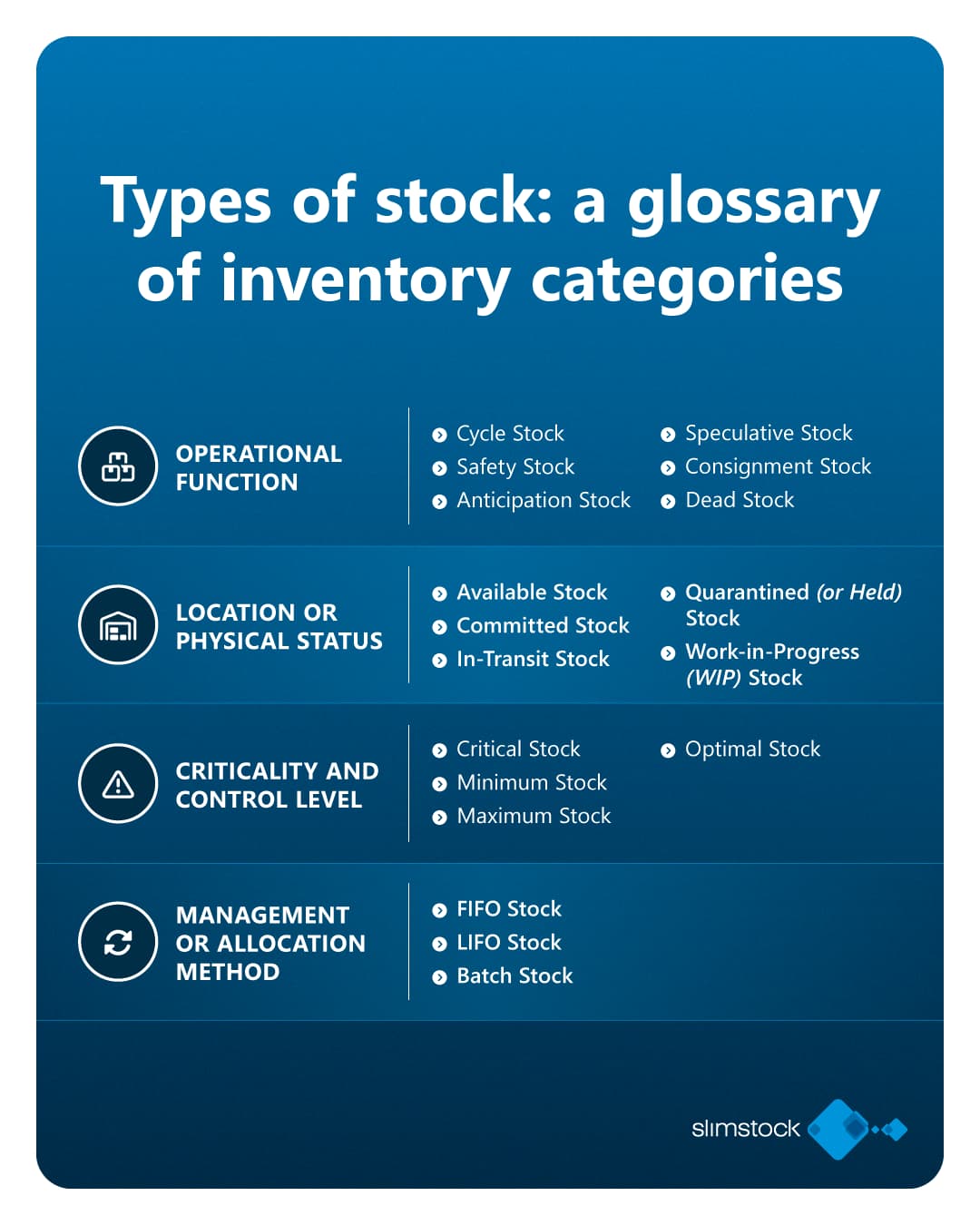

Table of contents- Types of inventory: a glossary of inventory categories

- What is stock?

- Types of inventory according to their operational function

- Types of inventory by location or physical condition

- Inventory by criticality and control level

- Types of inventory by allocation or management method

- Conclusion

- FAQs about types of stock

Overview

Inventory is categorized by operational function (cycle, safety, anticipation, speculative, consignment, dead), physical condition/location (available, committed, in-transit, quarantined, WIP), criticality/control (critical, minimum, maximum, optimal) and management method (FIFO, LIFO, batch), each serving a specific role in supply chain efficiency, cost control and service level achievement.

It’s not easy to classify the types of inventory that exist, as this categorisation can be made according to multiple perspectives: according to their operational function, their condition, their accounting value…

For this reason, in this article we are going to try to break down the most common types of inventory when we talk about inventory management.

What is stock?

Stock refers to the amount of products, material or goods that an organization holds in reserve for use, sale or transformation. Its effective management is key to ensuring availability, avoiding breakages and optimizing resources in the supply chain.

Types of inventory according to their operational function

In day-to-day inventory management practice, each type of inventory has a specific function in the company’s operations. Some ensure continuity of supply, others act as a buffer against uncertainty, and others allow us to anticipate peaks in demand or market variations. Inventory classification by operational function allows us to plan and optimize service levels by knowing how much stock we need, for what, and when.

Cycle stock

Also known as working stock, it refers to the amount of inventory needed to meet regular demand during a given period, between two consecutive replenishments. It represents the normal volume of consumption and is calculated based on the historical pattern of sales or consumption. It’s the “base” operating stock.

Safety stock

It is the overstock kept to cover uncertainty of demand or supplier lead time delay. Its objective is to avoid stock-outs and achieve a desired level of service. Demand fluctuation and supplier lead time are those variables that control the calculation of safety stock.

Anticipation stock

This type of stock is produced ahead of time in expectation of possible surges in demand, for instance, during festive seasons or promotion seasons. This facilitates effective response to surges in consumption without relying on real-time production or supply capacity.

Speculative stock

This involves purchasing inventory to anticipate changes in the market, i.e., increases in price or possible shortages. It is a planning action designed to take advantage of positive market conditions to realize future profits.

Consignment stock

This is stock which, although physically located on the customer’s premises, remains the property of the supplier until it is absorbed or onward-sold. It reduces the buyer’s tied capital and requires special arrangements in terms of duties and administration.

Dead stock

Also known as obsolete stock, this includes products that have been in the warehouse for a long period and are unlikely to be sold. This type of stock ties up resources and can negatively affect the company’s financial results.

Types of inventory by location or physical condition

Knowing where inventory is and what condition it’s in is key to effective management. This category helps us to understand the traceability of inventory and maintain an accurate and up-to-date view of actual stock levels.

Available stock

This is the inventory that is physically in the warehouse and ready to be used or dispatched without restriction. It represents the quantity of products that can immediately meet customer demand.

Committed stock

This is inventory that, although it is in the warehouse, has already been allocated to specific orders or other destinations and therefore is not available for new orders. Good management of availability and avoidance of overselling are vital.

In-transit stock

This is inventory that has been shipped by the supplier or is being moved between warehouses, but has not yet been physically received. Its proper management is crucial to maintain accurate inventory levels and to plan replenishment correctly.

Quarantined or held stock

This refers to inventory that has been temporarily set aside due to quality inspections, pending documentation or administrative decisions. It cannot be used until the conditions that caused it to be held are resolved.

Work in progress (WIP) stock

This is inventory that is in the process of transformation within the production plant. It’s neither raw material nor finished product, and its correct management allows measuring efficiency and costs in manufacturing industries.

Inventory by criticality and control level

Not all inventory has the same impact on a company’s operation or finances. Some items are critical to avoid disruptions in production or service, while others may be excess inventory that generates unnecessary costs. By classifying stock according to its strategic or accounting value, we can align inventory policies with business objectives, improving financial control and tactical decision making.

Critical stock

This refers to those items whose absence can stop or seriously impact operation due to their specialised nature or strategic value. Its control must be rigorous, with agile replenishment protocols to ensure operational continuity.

Minimum stock

This is the lowest level of inventory that needs to be carried in order to operate without risk of interruption. Its characterisation depends on the criticality of the product and the volatility of demand.

Maximum stock

This is the highest level of inventory that can be carried in order not to overstock, grow obsolete or have too much in terms of inventory cost. It’s a buffer for replenishment that is helpful in space and cash flow optimisation.

Optimal stock

This is the ideal level of inventory that balanced storage cost, ordering cost and service level. It’s where economic and operational efficiency is maximised.

Types of inventory by allocation or management method

The way we store and move the stock also decides the way it responds in the warehouse. FIFO or LIFO strategies, or batch control, dictate stock valuation, turnover, traceability and regulatory compliance directly. We need to learn these methods so that we can create useful working procedures from product characteristics and market needs.

FIFO stock

“First In, First Out“. A method in which the oldest units of inventory are dispatched first. It’s advisable for perishable or time-sensitive products, as it helps to reduce obsolescence and losses.

LIFO stock

“Last In, First Out”. A method that prioritises the dispatch of the most recently arrived units in inventory.

Batch stock

It refers to quantities held batchwise with the same identification but different specifications, e.g., date of manufacture or serial number. It is required in those industries where traceability is critical, e.g., food or pharmaceuticals.

Conclusion

Stock management is in our DNA as a company. It’s not an accident, look at our name. Hopefully this dictionary of ideas on the various types of inventory will help you to have a clearer understanding of these basic concepts. If you’d like to learn more about inventory management, don’t hesitate to consult our free training courses.

FAQs about types of stock

What is stock?

Stock refers to the amount of products, material or goods that an organization holds in reserve for use, sale or transformation. Its effective management is key to ensuring availability, avoiding breakages and optimizing resources in the supply chain.

What are the various types of stock?

There are some types of stock based on their function, status, strategic value or management type. The most common ones are:

- Based on functional operation: safety stock, cycle stock, anticipation stock, speculation stock, consignment stock, dead stock.

- Based on status: stock on hand, committed, in transit, in quarantine, in production.

- Based on strategic value: minimum, maximum, optimum, critical stock.

- Based on management approach: FIFO, LIFO, stock by lot.

What is stock management?

Stock control is the group of processes, techniques and decisions which facilitate efficient management of a firm’s stock. Its main aim is to make the correct product, at the correct time and in the correct location, with minimal overstocking and understocking.

They include activities such as demand planning, minimum and maximum level control, rotation, replenishment, and product classification. Proper stock management leads to cost savings, improved service levels, and supply chain optimisation.