Table of contents

Table of contents- Supply chain disruptions: How S&OP can prepare us for the future

- Why do disruptions continue to be so costly?

- S&OP as a risk management tool

- Proactive planning: a real example of anticipation

- 10 steps to improve your S&OP

- S&OP as a competitive advantage

Overview

Supply chain disruptions are increasingly common and costly, making preparedness a key strategic differentiator. Sales & Operations Planning (S&OP) is a critical tool for risk management and resilience, enabling companies to achieve a holistic view of demand and supply, simulate scenarios, diversify suppliers and integrate all departments to proactively plan for and quickly recover from unforeseen events like political instability, natural disasters, or strikes, ultimately providing a competitive advantage.

Supply chain disruptions are part of the global landscape and, historically, have become increasingly frequent and complex. Pandemics, natural disasters, geopolitical tensions, strikes, and extreme climate impacts pose recurring challenges to logistics operations and global supply.

In this scenario, the ability to anticipate and respond has become a strategic differentiator for companies seeking to maintain competitiveness and operational continuity. The question is not if it will happen again, but how we are preparing for when it does.

At the S&OP Experience 2025, an event held in São Paulo, experts discussed ways to make planning more robust and better prepared for unforeseen events. Among the central topics, the role of Sales & Operations Planning (S&OP) as a tool for risk management and resilience stood out.

Why do disruptions continue to be so costly?

According to the study The Business Cost of Supply Chain Disruption, cited during the presentation, companies spend an average of $184 million per year on disruptions to their supply chains. Of these:

- 33% face increased operational costs.

- 38% report reputational damage.

- 18% report direct revenue loss.

In addition to the immediate effects, new risk factors are already shaping the current landscape: political instability, cyberattacks, economic volatility, and shifts in the profile of new generations of professionals.

In this context, the adoption of more integrated processes and supporting technologies has become essential. And this is where S&OP takes on a new role as a catalyst for transformation.

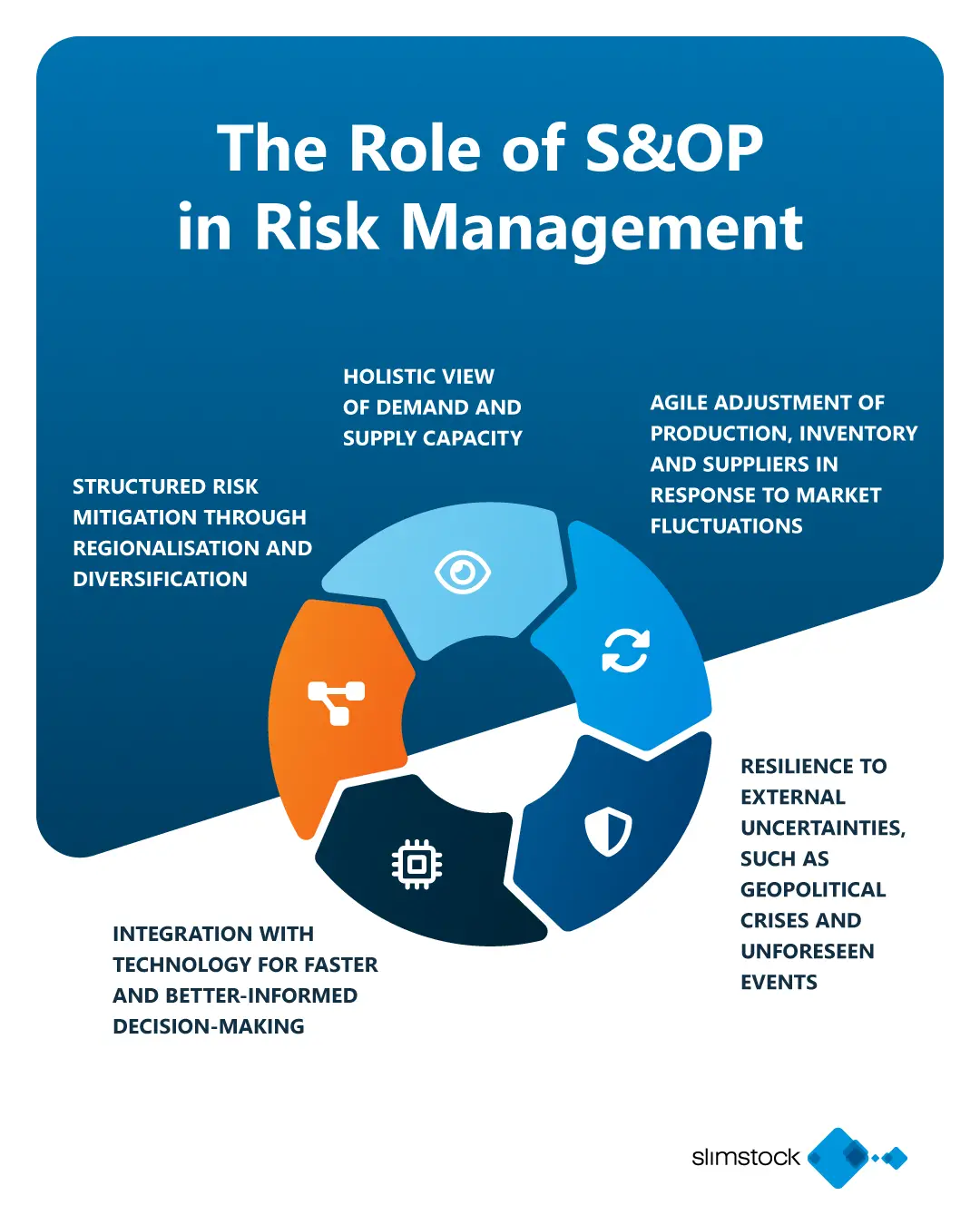

S&OP as a risk management tool

More than just a process for aligning sales and operations, S&OP is now a central instrument in companies’ resilience strategies. When well-structured, it enables the anticipation of disruptions, the creation of contingency plans, and agile responses to market changes.

Recent data reinforce the relevance of this process:

- 80% of companies that simulate scenarios recover more quickly from disruptions (Deloitte).

- Up to 20% reduction in the gap between forecasted and actual demand (Gartner)

- 72% of companies that apply AI to S&OP improve visibility and reduce operational risks (McKinsey).

How S&OP helps manage risk

- Holistic view of demand and supply capacity.

- Agile adjustment of production, inventory, and suppliers according to market fluctuations.

- Resilience to external uncertainties such as geopolitical crises and unexpected events.

- Integration with technology for faster and more informed decision-making.

- Structured risk mitigation through regionalization and diversification.

Proactive planning: a real example of anticipation

During the event, a real case was presented that demonstrated the value of early planning. In 2024, faced with the possibility of a strike at U.S. ports, a warning was issued more than three months in advance. From this alert, the supply chain team activated the S&OP cycle and began mapping out scenarios and impacts.

With support from the finance and commercial teams, mitigation actions were put in place, such as early purchasing, adjustment of strategic inventories, and rerouting of logistics flows. Communication with customers was transparent from the beginning, generating trust and predictability even in the face of uncertainty.

10 steps to improve your S&OP

Building a robust S&OP process requires organization, strategic vision, and cross-functional collaboration. Below is a set of best practices to help prepare the process for disruptions:

- Stay informed: monitor global events and regulatory trends.

- Understand your supply chain: know your suppliers, lead times, and interdependencies well.

- Adjust inventory and lead time policies: be ready to advance or delay movements.

- Involve procurement and contracts: ensure agreements are aligned with the S&OP cycle.

- Diversify suppliers: avoid dependence on a single source;.

- Invest in technology and data: AI and digital platforms are key for scenario analysis.

- Simulate risks and plan responses: map out alternatives for critical events.

- Integrate all departments: from operations to commercial, including logistics, IT, and finance.

- Create a crisis response plan: define responsibilities and clear decision-making flows.

- Monitor and continuously adjust: KPIs must reflect reality and guide next steps.

S&OP as a competitive advantage

Adopting a strategic S&OP allows companies not only to absorb shocks and react accordingly but also to stand out for their adaptability. In a world where disruptions have become the rule, not the exception, integrated planning becomes more than a best practice: it’s a competitive advantage for those seeking consistent growth, even in uncertain environments. Tools like Slimstock’s Sales & Operations Planning software make this agility achievable by providing seamless collaboration and data-driven insights across the business.