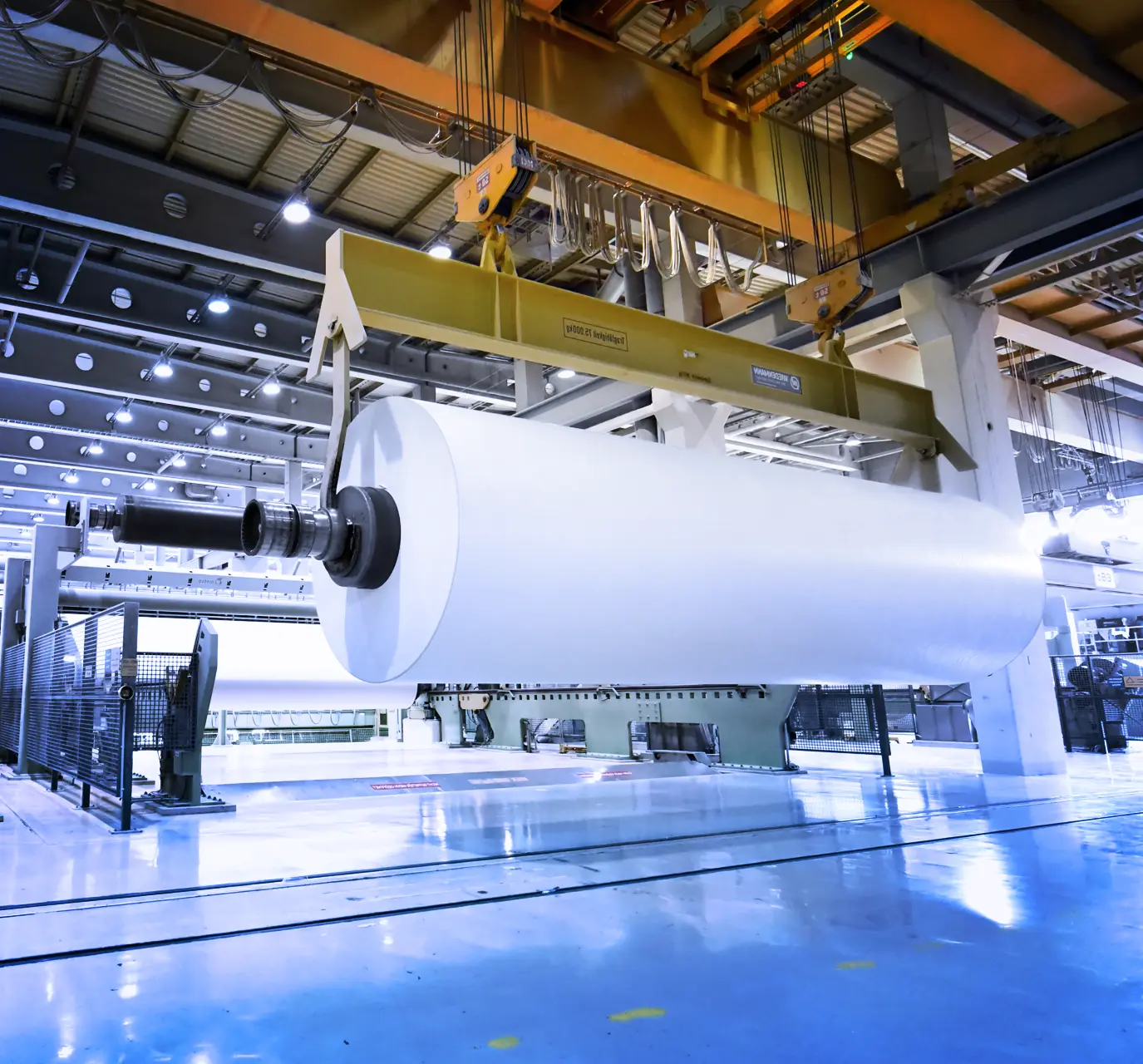

Paper & packaging

Unrivalled forecasting precision in a market on the move

Slimstock helps companies overcome a drastically shifting paper & packaging market, helping to anticipate a new demand trajectory through automated analysis, prioritisation, and inventory management.

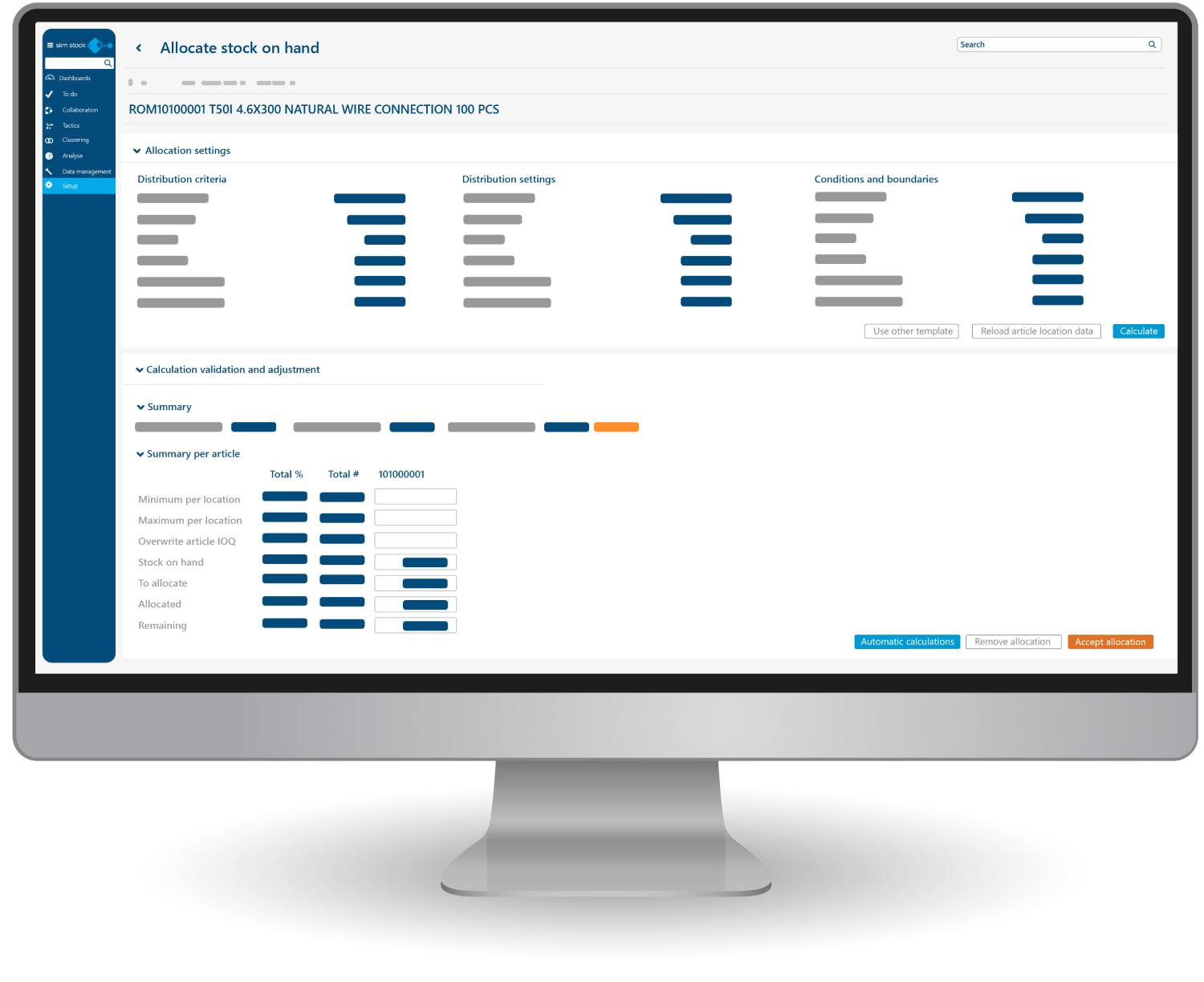

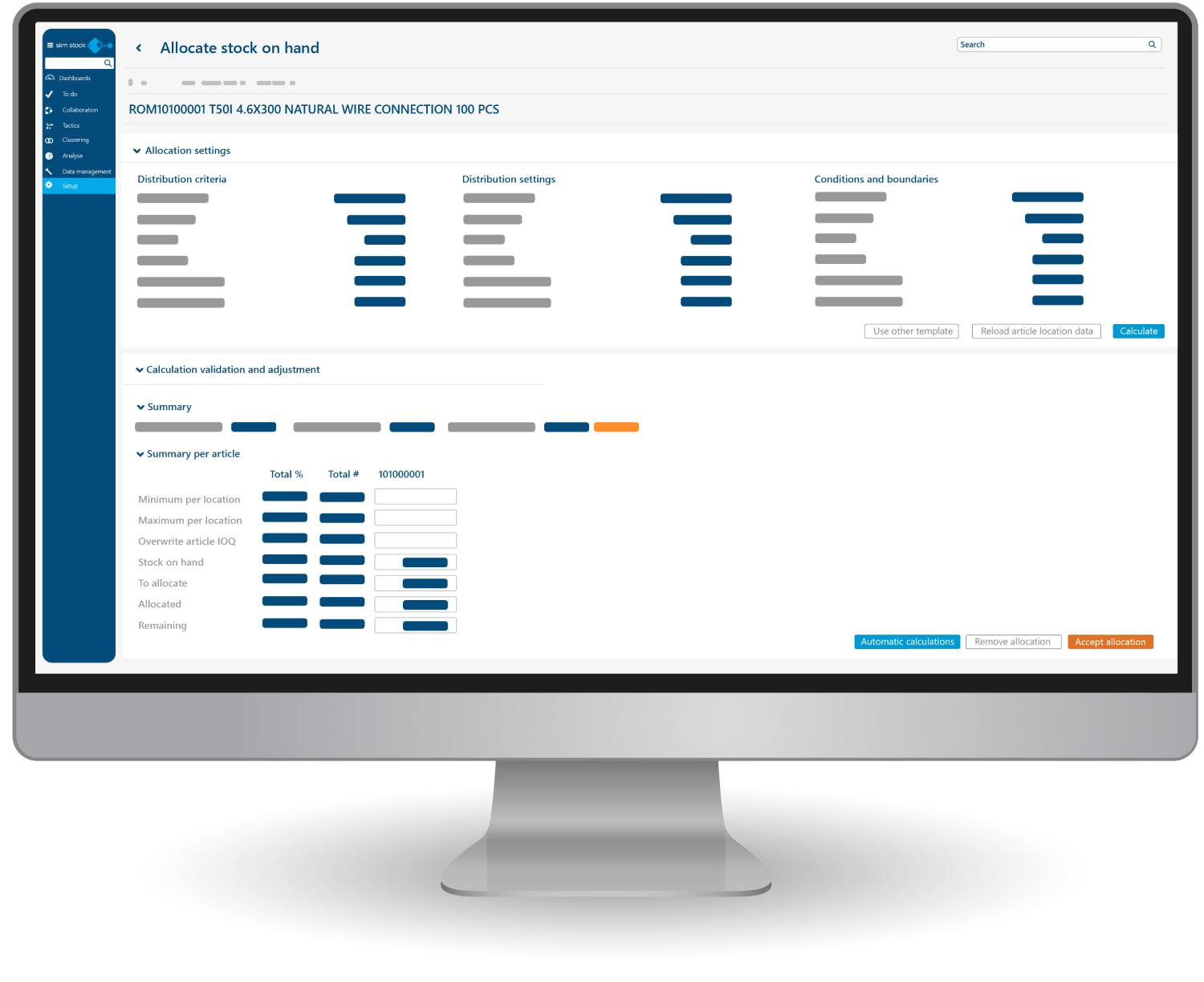

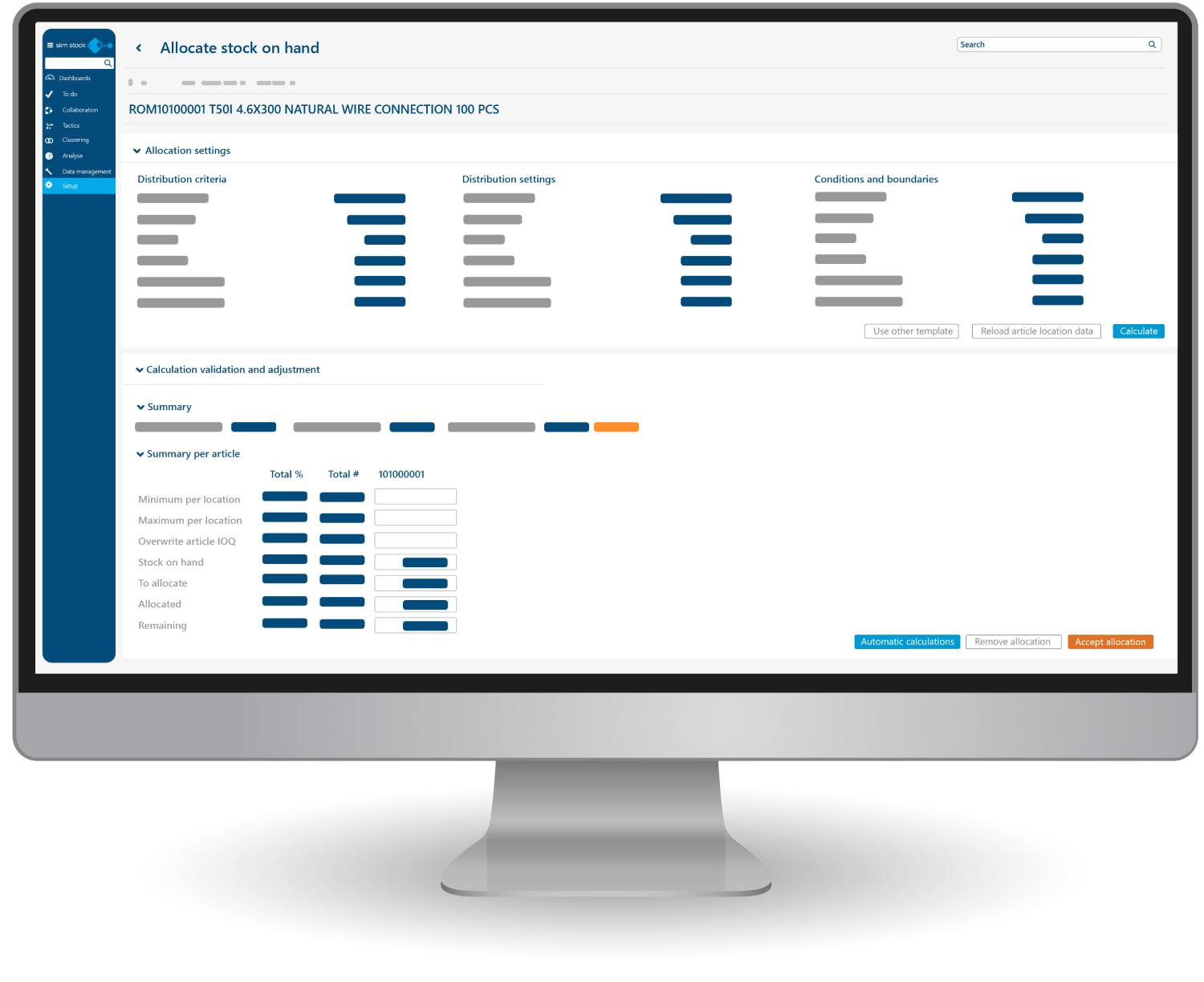

Slim4’s key features for paper & packaging

Slimstock’s holistic platform provides powerful, industry-specific tools to transform supply chain planning and execution for the paper & packaging sector.

Modernise your stocking policy

Slim4’s stock policy module is adaptable to each item’s value. Through analysis of end-to-end data and the market, prioritise with precision for maximised margins.

Know in real-time which items are most important to your business, in terms of clearing stock, meeting demand, and maximising profits.

Ensure availability despite the current complexity of avoiding either overstocking or stockouts. Be the one to show you can pivot to modern-day paper & packaging requirements.

Slim4’s AI-driven algorithms balance historical demand against the real-time situation to ensure that perfect balance between availability and waste. This drives both customer loyalty and business sustainability.

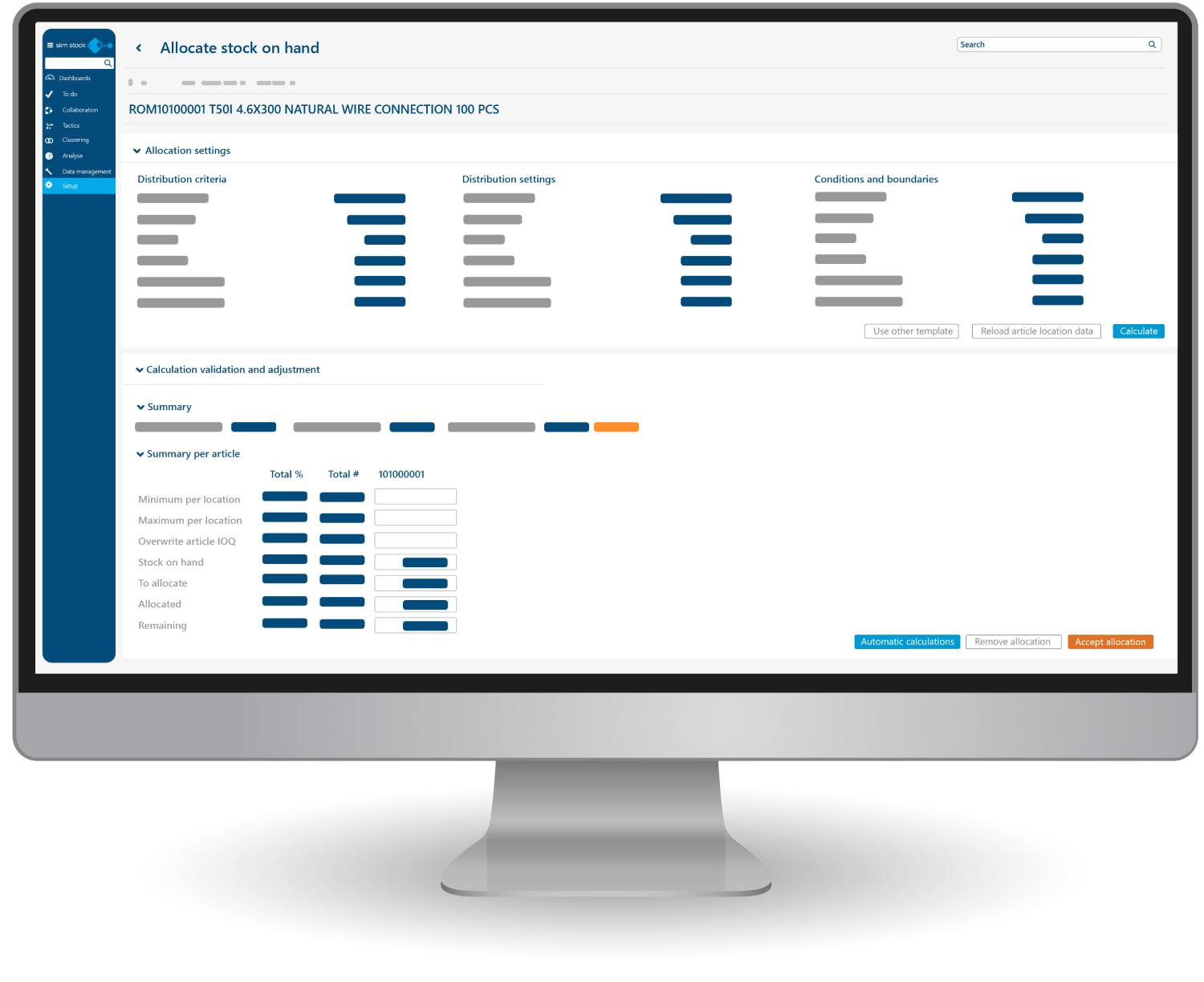

Multi-echelon inventory optimisation (MEIO)

Manage inventory in the most efficient way across channels and locations, to offset any issues of overstocking or stockouts in localised areas.

EOQ and inventory optimisation

Don’t just optimise the demand side of the equation. Refine supply and procurement to ensure maximised margins for every product. Slim4’s EOQ module ensures you’re ordering to what’s possible, not just what’s needed.

Kick Start Your S&OP in 90 Days

Launch a result-driven S&OP process in just one quarter. Simple, focused and proven

Download

Find out how you

can

See Slim4 in action

From our customers to you

Game-changer for our Supply Chain performance.

Once we had decided on which Supply Chain planning software you implement, it was a relatively straightforward implementation. We had great support from the Slimstock implementation team throughout the whole process.

Slim4 has helped us centralize our purchasing, which has led to less time spent overall when it comes to purchasing.

At the same time we have increased our service levels to customers by several percentage points while keeping our stock levels low.

Slim4 was an easy tool to learn with an intuitive interface.

The team was quite hands-on in getting the implementation done as efficiently as possible and the results were quite evident from the get-go.

Speak to one of our experts

Book a 1-2-1 demo