Industrial components

Innovate and accelerate your industrial supply chain

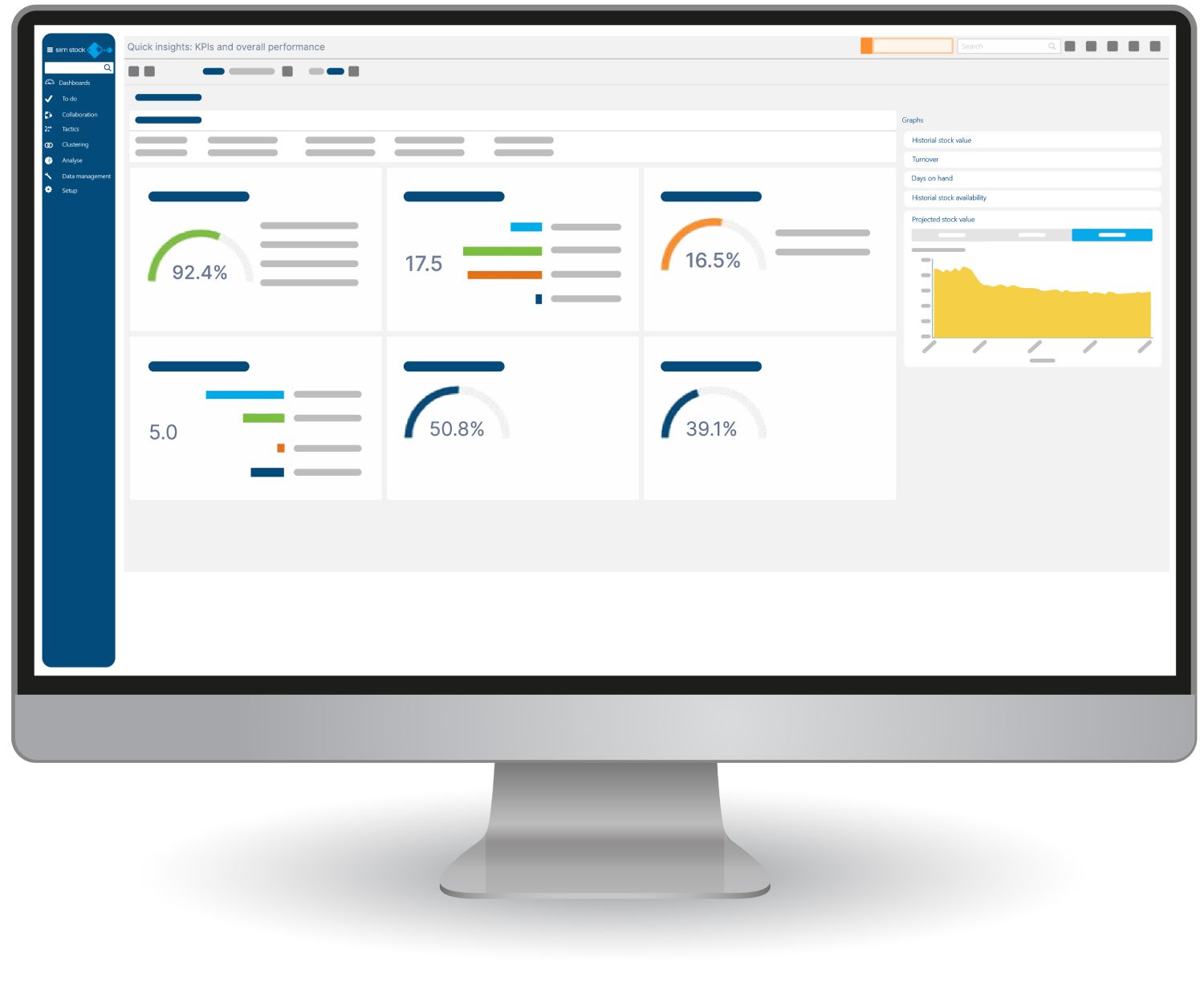

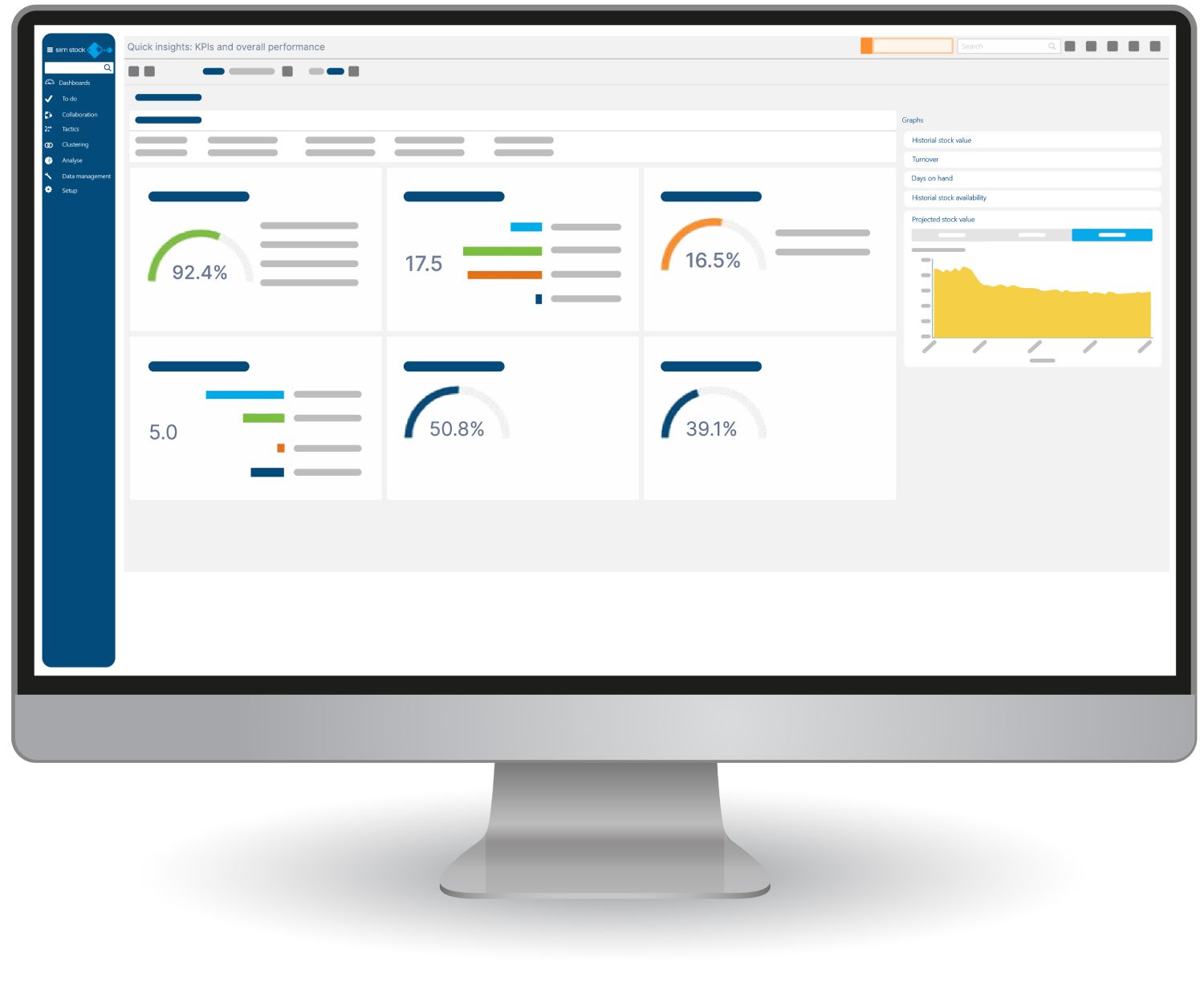

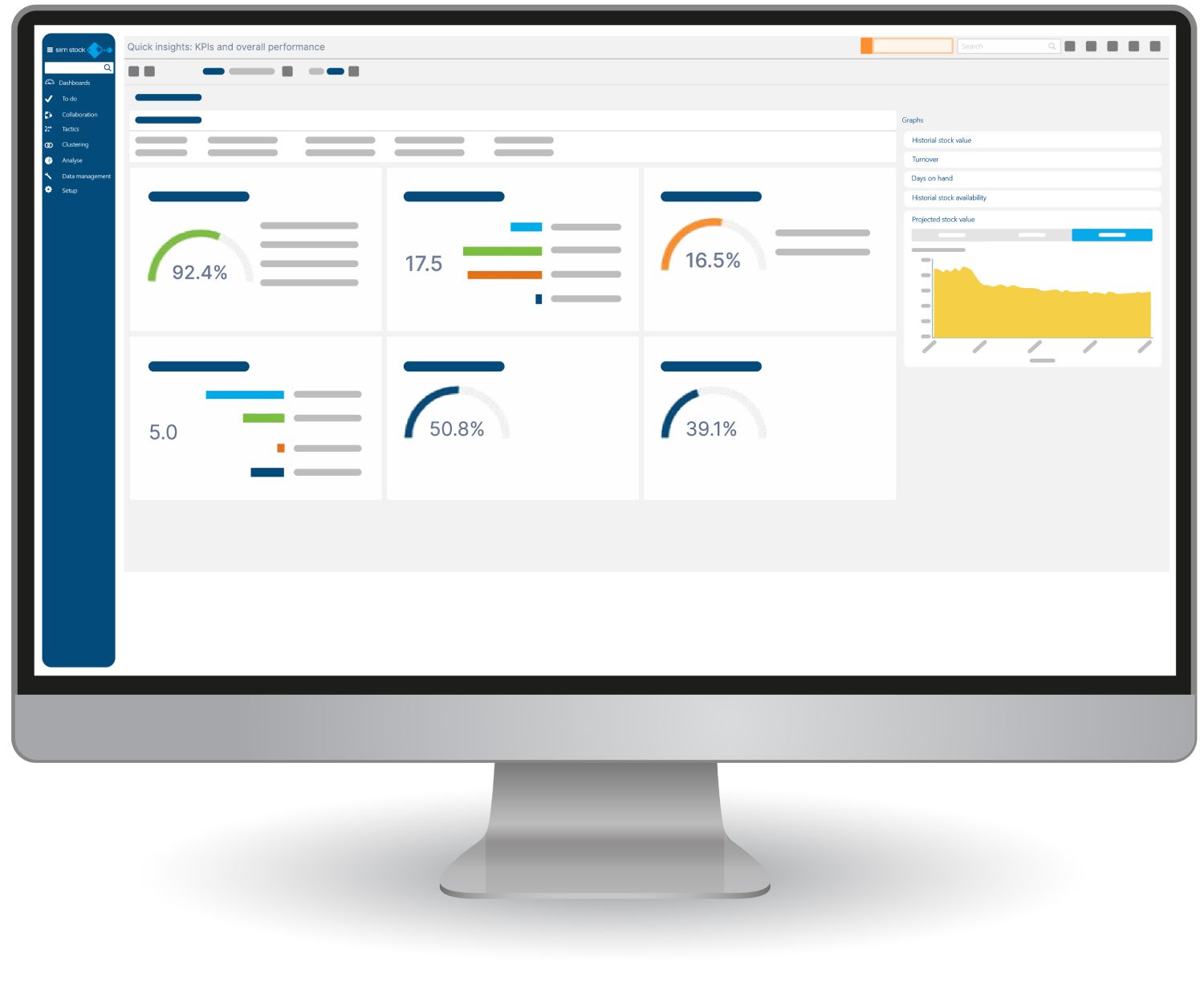

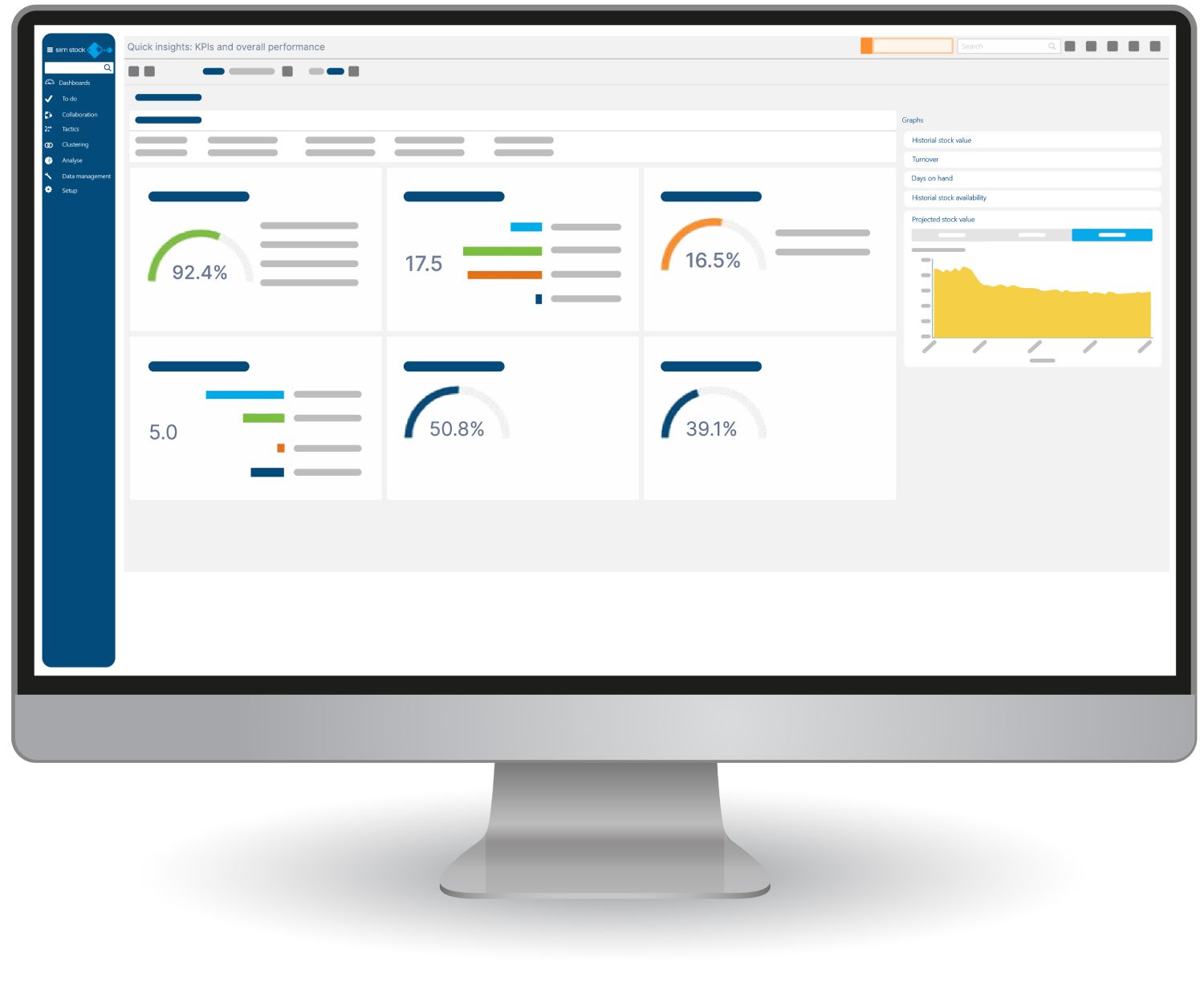

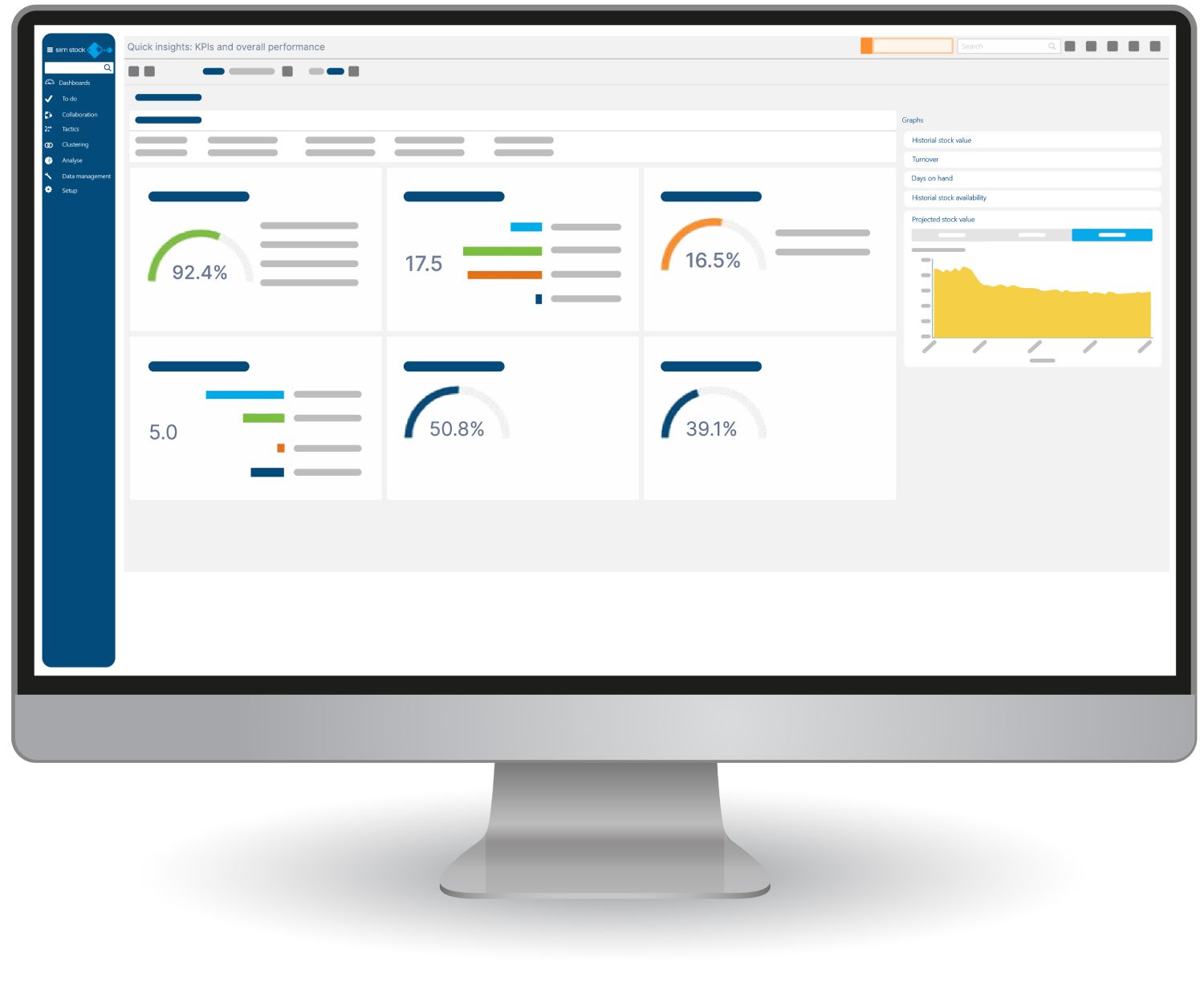

One-fifth of Slimstock’s client base come from the industrial components sector, each benefiting from our Slim4 platform which helps to manage large product assortment by exception, optimise purchasing, and simplify ordering.

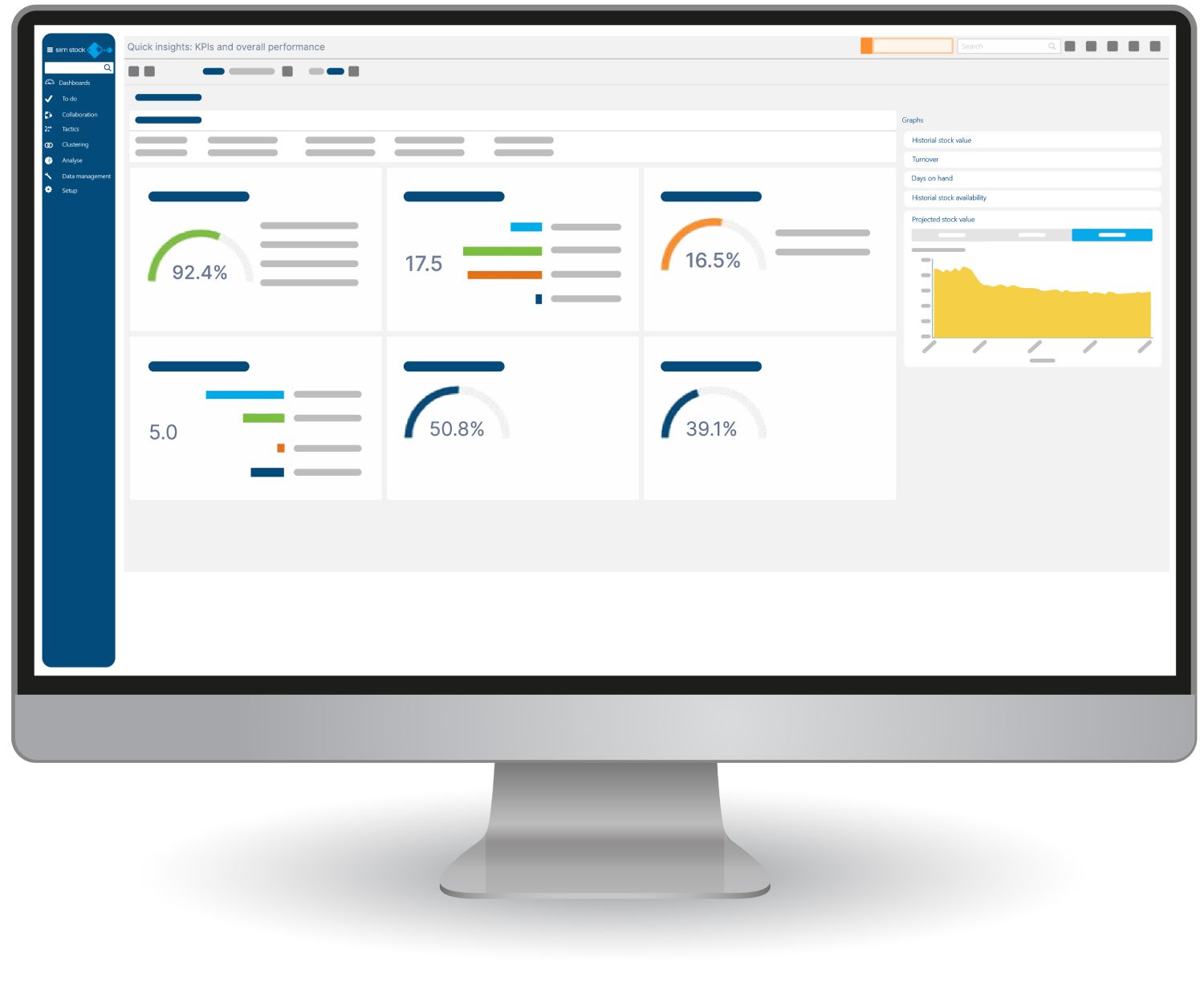

Slim4’s key features for industrial components

Slimstock’s holistic platform provides powerful, industry-specific tools to transform supply chain planning and execution for the industrial components sector.

Slim4 optimises replenishment and supply processes across the logistics chain, with automated purchase decisions ultimately contributing to availability rates of up to 99%. For decision-makers, an exception management to-do list further optimised resource allocation and workflow speed.

Slim4’s tactics modules helps to optimise stocking policies and simulate the impact of alternative service level targets.

Product lifecycle (PLC) manager

From launch to discontinuation, industrial component PLC management requires data-driven automation to reduce excess and avoid obsolescence. Slim4 helps to reduce excess stock by up to 50%.

Advanced forecasting models are tailored to different demand patterns, allowing for more accurate predictions that factor in potential disruptions and long lead times.

Slim4 reduces inventory levels between 10-30% without risking availability. Source, assort, locate, and store in an optimised way to segment efficiently, reduce manual workloads, and maximise profits.

Slim4’s BOM and production planning functions ensure complete synchronisation between initial raw material decisions, and the finished products required.

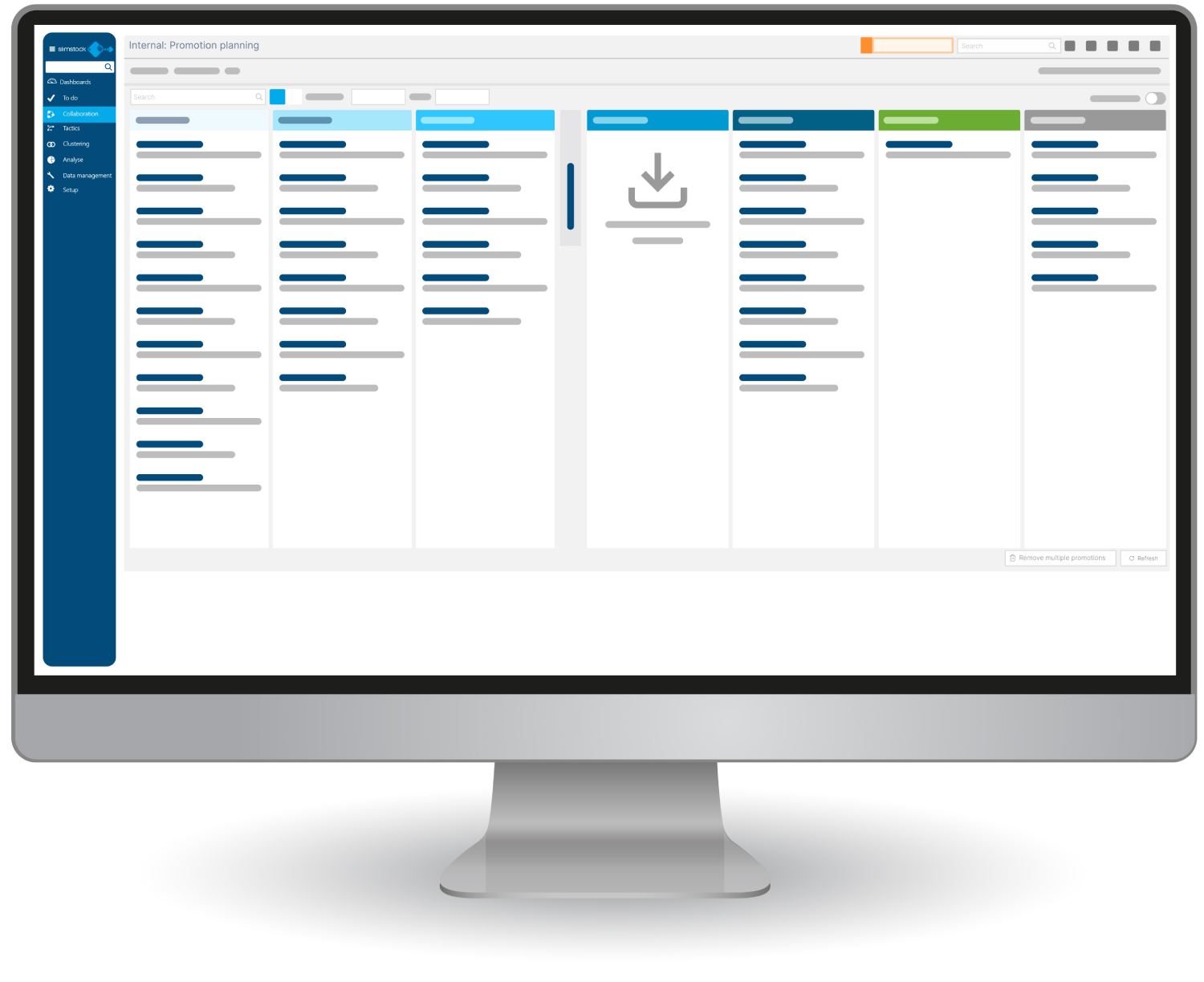

Kick Start Your S&OP in 90 Days

Launch a result-driven S&OP process in just one quarter. Simple, focused and proven

Download

Find out how you

can

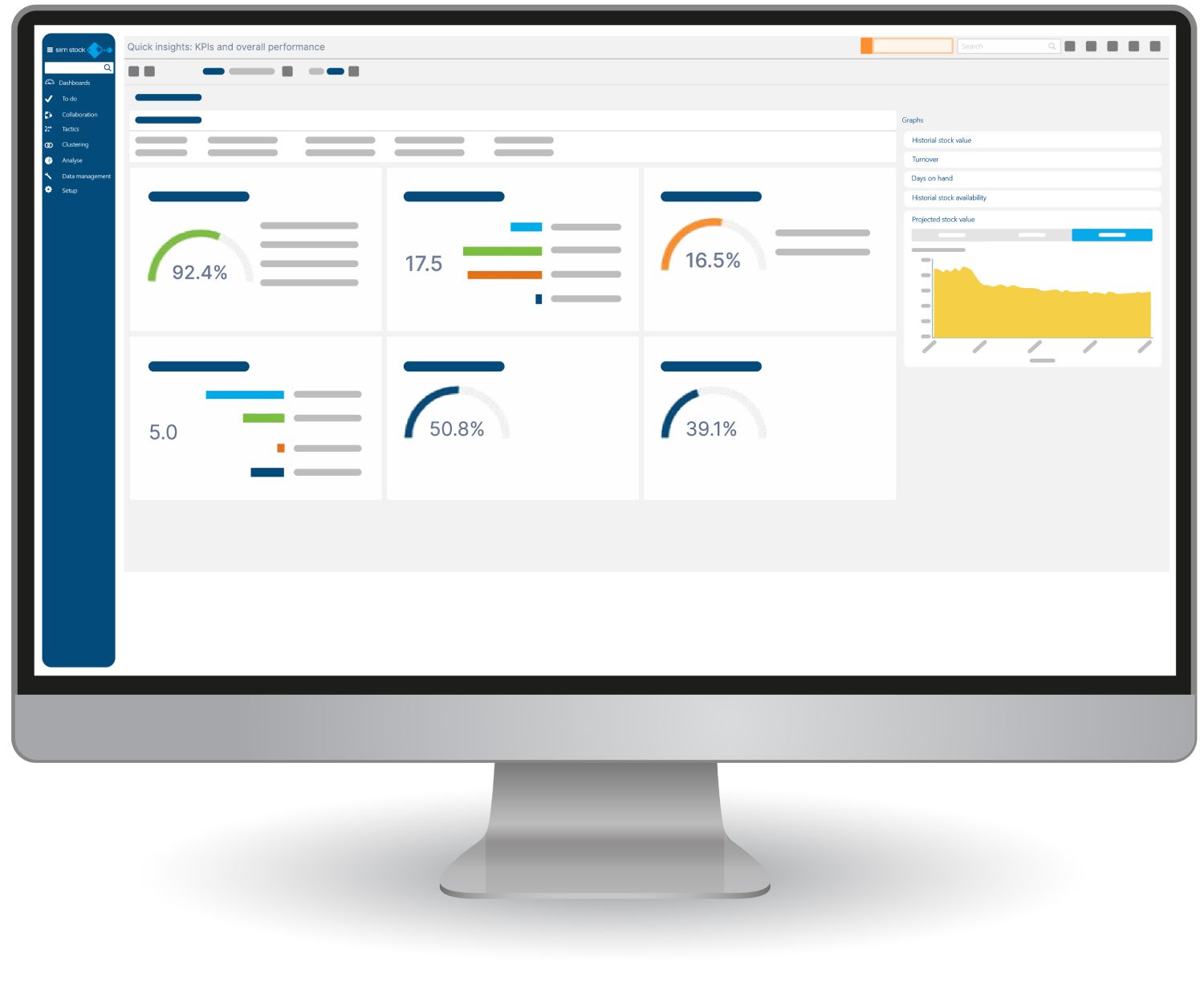

See Slim4 in action

From our customers to you

Game-changer for our Supply Chain performance.

Once we had decided on which Supply Chain planning software you implement, it was a relatively straightforward implementation. We had great support from the Slimstock implementation team throughout the whole process.

Slim4 has helped us centralize our purchasing, which has led to less time spent overall when it comes to purchasing.

At the same time we have increased our service levels to customers by several percentage points while keeping our stock levels low.

Slim4 was an easy tool to learn with an intuitive interface.

The team was quite hands-on in getting the implementation done as efficiently as possible and the results were quite evident from the get-go.

Speak to one of our experts

Book a 1-2-1 demo