Furukawa Rock Drill (FRD) has transformed its European spare parts operation with the help of Slimstock’s supply chain planning solution to forecast demand more accurately, optimise stock levels and seamlessly manage product lifecycles, delivering a service level that now exceeds 96%.

The Japanese company Furukawa Rock Drill (FRD) manufactures hydraulic demolition hammers and drilling machines that are used in mining, as well as in demolition and recycling work. The range of demolition hammers varies in size from “small” 70 kg devices to giant 6.5-tonne machines that are attached to excavators. Subsidiary FRD Europe is responsible for distribution within Europe, Russia and a large part of Africa. The machines and associated spare parts are delivered to regional dealers from the distribution centre (DC) in Utrecht.

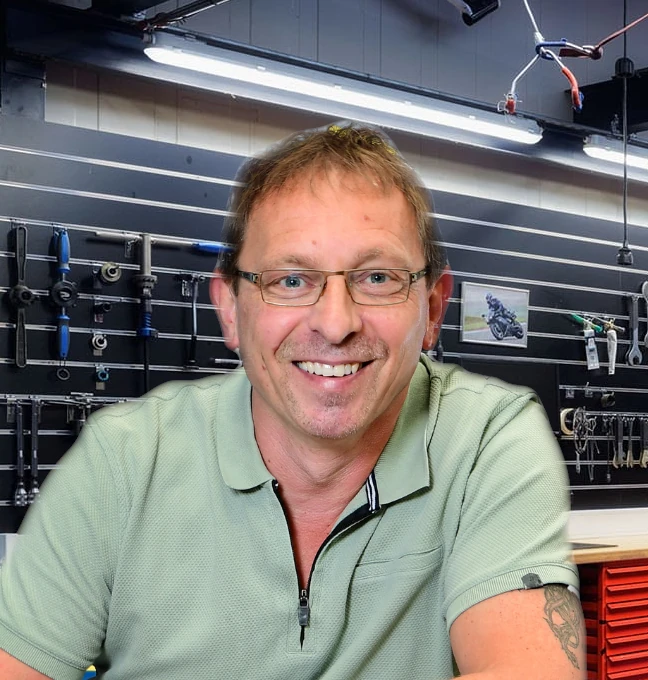

‘The most challenging part is the spare parts,’ says procurement executive Nico van Manen, who, together with his colleague Claudine de Kruif, is responsible for purchasing and inventory management at FRD Europe. “We have more than 70,000 items in our database, but only a fraction of those are actually ordered. There are wear parts that need to be replaced regularly depending on usage, but there are also parts that hardly ever break down and are only needed a few years after commissioning. So, it’s important for us to keep track of which machines have been sold in our region and what we stock, and when.”

Finding the right solution

In 2015, FRD implemented a new ERP system, but its stock module proved too static to cope with the dynamics surrounding spare parts. The ERP calculated a fixed minimum stock level and simply used the average demand from the previous year as a forecast. ‘Spare parts were always automatically reordered, even those that you knew would never be sold again,’ says stock manager De Kruif.

‘The ERP system was also unable to handle the new product versions that Furukawa regularly releases. Because new item numbers are created for these, the ERP system thinks they are completely new parts. You then lose your entire sales history and have to start from scratch in terms of inventory management.’

To gain more insight into demand and improve inventory control, the company decided to implement Slimstock’s supply chain planning solution. Van Manen highlighted: “We were looking for an advanced tool that could forecast sales patterns and respond to them with inventory. Slimstock’s platform proved to be the perfect solution for us. Spare parts are only put into stock when there is actual demand for them, and at the end of their life cycle, they are automatically phased out. The software also takes new product versions into account and bases its forecast on the historical sales patterns of their predecessors.”

Service level increase

Van Manen and De Kruif say they are pleasantly surprised by the speed with which inventory performance has improved since the implementation of Slimstock’s solution. ‘We were at a service level of 80%, which meant we couldn’t always deliver from stock. The fact that we sometimes had to offer long delivery times instead was unacceptable to our customers and to us. Our goal was to get this to 90% after one year and to 92%-95% after two years. Surprisingly, we were already at 96% before finishing the first year after implementation.’

For De Kruif, the introduction of Slimstock’s solution revolutionised the working processes. She states: “It saves me so much time. Previously, I spent hours every week checking all the items and verifying that the order recommendations were correct. Now I only have to process the exceptions. If I want to check something, I can quickly see how an order proposal was generated. You can click through to an item and immediately see how the sales pattern is developing.”

Insight into lifecycles

Slimstock’s software has given FRD the desired insight into the lifecycles of items, enabling it to determine exactly when a part needs to be put into stock. Van Manen explains: “We were always under a lot of pressure from Japan to keep as wide a range of spare parts in stock as possible. An analysis in Slimstock’s software revealed how much excess stock we had built up as a result, which was quite shocking. In hindsight, it would have been much better not to have stocked many of the items. We now have a process in place whereby we only stock items when there is a real demand for them. The first order may be a rush order, but after that, the item is included in the system and the optimal stock level is automatically built up.”

What remains for FRD now is to reduce the excess stock. That is quite a meticulous job, Van Manen emphasises: “We have to look carefully at what is really surplus and what may still be in demand at a later stage. We have made all kinds of analyses for this within Slimstock’s software and defined separate item categories for this in the ERP. We still have to decide whether to remove these items from the range entirely or whether to keep a minimal stock of them.”

Top-notch stock management

The two have been working for FRD for quite some time and have been responsible for the entire stock management for decades. ‘In total, we have been working for this company for more than half a century,’ says Van Manen with a smile. ‘Now, with Slimstock, I feel for the first time that we have really got a complete grip on it. Phasing in and out items, managing exceptions, performing analyses, reducing excess stock… that’s top-notch inventory management as it should be.’