Overview

Supply Chain Operations must be involved in the Sales & Operations Planning (S&OP) process, beyond just the planning teams, because decisions about product mix and forecasting directly impact operational aspects like labor, transport and warehousing capacity. Their involvement is vital for communicating non-negotiable constraints, managing costs, optimizing resource utilization and ultimately ensuring the achievement of revenue goals by enabling better planning for receiving, shipping and production.

Sales & Operations Planning (S&OP) is often viewed primarily as a planning exercise, bringing together demand and supply planning teams with the aim of ensuring optimal inventory levels and excellent customer service.

Although Supply Chain Planning (SCP) teams are often at the core of generating data, the role of supply chain operations should not be overlooked. Decisions made during the S&OP process often affect labour, transport and warehousing, making it vital that operations have a seat at the table when these decisions are made.

Why should operations be at the table

There is a key difference between planning and operations. Where planning is mostly concerned with planning the right product mix, for operations the mix is less relevant to a certain extent. Of course, you need to pick and ship the right product, but from a planning (labour, capacity) perspective as an operations team, you’re more concerned about the bigger picture. Only caring about the mix that is relevant for you (e.g. shipping large orders to distributors, or small orders to end-consumers, or are you shipping small parts or TV’s).

This difference can make planning feel tedious for operations teams, too much irrelevant detail. However, in S&OP the focus should be on aggregate, family-level planning across different Units of Measure (UoMs). Some of these UoMs will be relevant for supply chain operations when discussing pallets, order lines or other translations of the mix forecast. This can help operations plan better for labour, capacity and prioritisation of orders, and more importantly: manage costs.

On the other hand, operations might have non-negotiable constraints. If it’s clear that the number of picking lines will rise above labour capacity, planning and operations can work together to pre-load stores or customers at quieter times. This will balance out the capacity, prevent overtime and ensure customer service.

What can operations gain from participating

Although operations teams have little influence to increase revenue and do something about budget gaps, they do play a crucial role in achieving revenue goals. By clearly communicating constraints with regards to capacity and labour, the planning teams can take decisions which will help circumvent constraints, or at least be the optimal choice between overtime and more inventory.

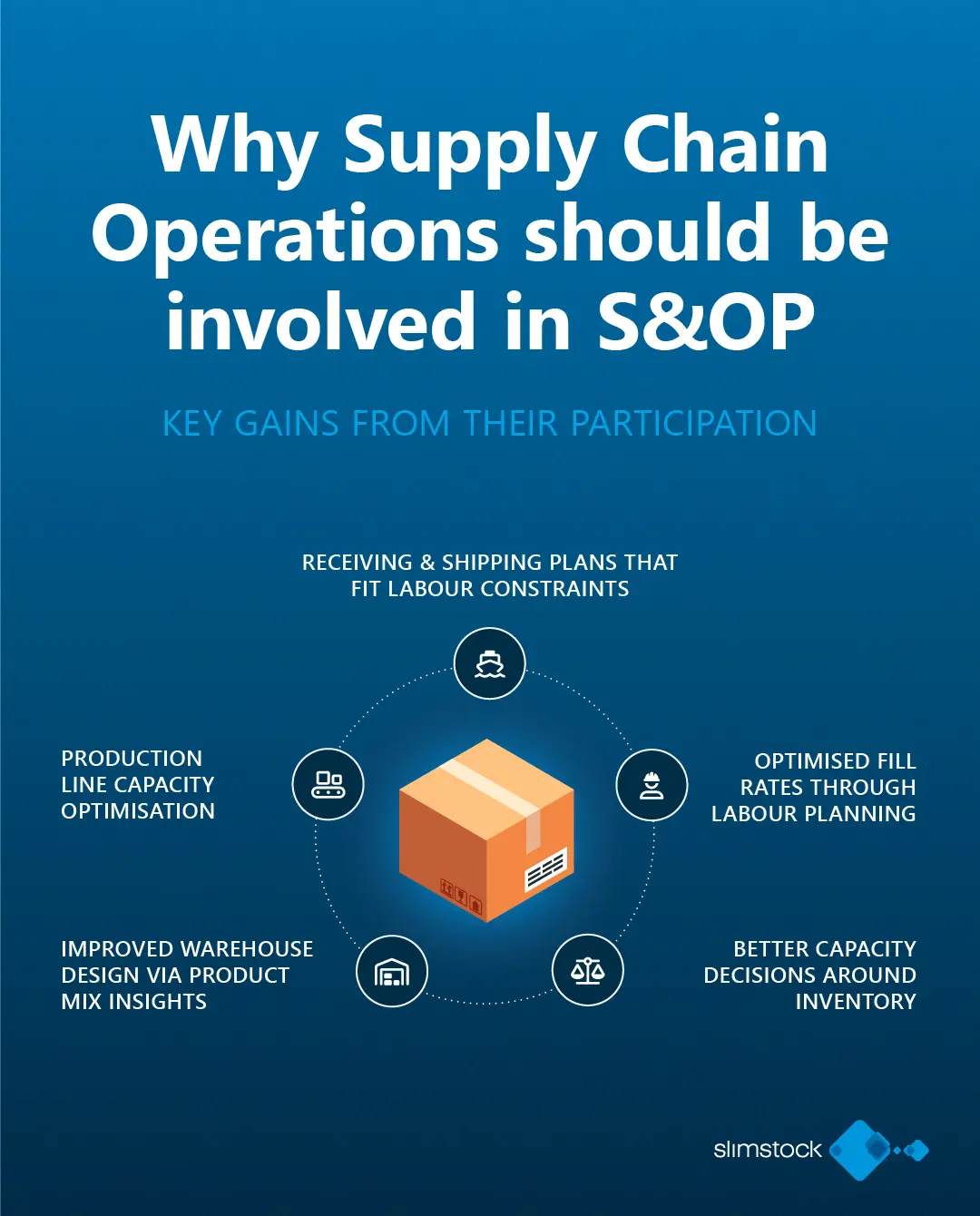

In essence, operations can expect the following gains:

1. A receiving and shipping plan which fits labour constraints

Early receiving or shipping can help spread workload, reducing peaks without compromising service.

2. Optimised fill rates through better labour planning

Striking the right balance between permanent and temporary labour can enhance efficiency.

3. Better capacity decisions around inventory

Managing capacity will improve the overall performance of a warehouse.

4. Better warehouse design through product mix information

Knowing what in the mix is picked more often will allow better warehouse design.

5. Production line capacity optimisation

Better demand and product mix information will allow for optimising production line yields.

Together, these gains reduce shipping costs and minimise waste in labour and capacity.

S&OP contribution is a must

Ultimately, operations have information about the most important constraints which will affect a business because warehouses and production lines are not easily up-scaled. Even labour is something that is expensive to upscale and only sustainable for short periods of time. For this reason, collaborating with supply chain planning teams is crucial to optimise the use of available resources and improve cost effectiveness.