Vendor Managed Inventory (VMI) is not a new concept. It’s been around for decades. But it’s a process you’ll need to be familiar with if the trend of food retailers asking their suppliers to be more proactive continues.

If you embrace this approach, there are several considerations to look at.

Firstly, you’ll need to be planning external inventories carefully. Secondly, you’ll be dealing with tight service level needs, and finally, your control of costs must be rigid.

That’s a lot to handle. But it’s very doable with the six tips we provide below.

As the concept gains popularity in the food supply chain, specifically with supermarket chains, suppliers can better manage their inventory levels more accurately and with time on their side.

The positives of taking on an approach like VMI are that you’ll gain a closer relationship with your customers and might also realise better commercial opportunities. But there are pitfalls.

If the correct amount of inventory is not supplied or the timing is wrong, you’ll find yourself in trouble quite quickly, forcing a reactive approach once more.

Equally, if supply chain costs become inflated or shrinkage grows, you’ll be in a similarly sticky patch.

VMI can be complicated. You need the most up-to-date information at your disposal and the best support.

At Slimstock, we understand the power of VMI. Managed correctly, it can unlock far higher performance in your supply chain, especially in the Food industry. We’ve assisted many businesses through the transition. And so, while we know what can inspire its success, we also know where the process can go wrong.

What is Vendor Managed Inventory (VMI)?

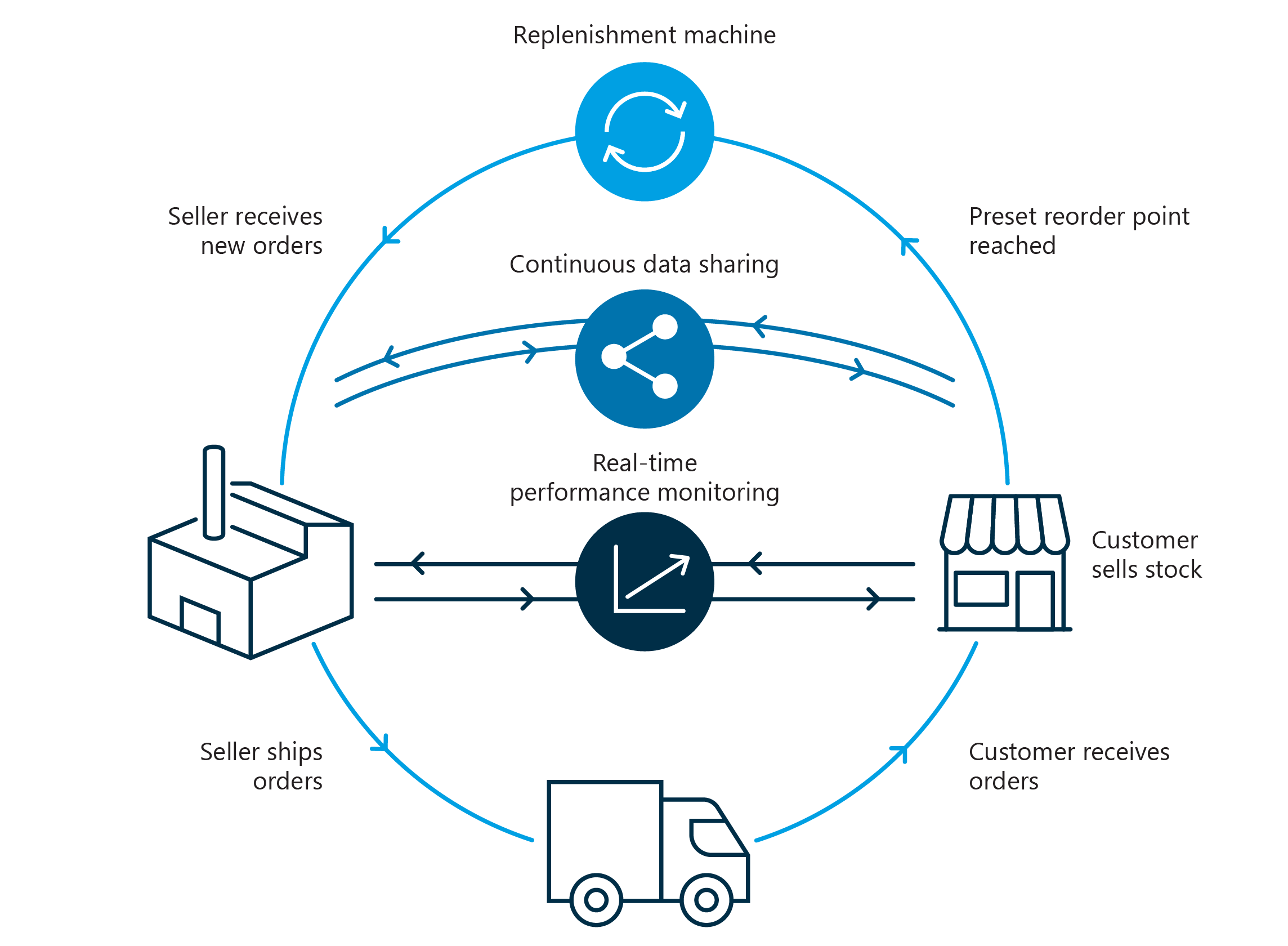

Simply, it’s when a supplier manages the inventory at their customer’s location. For example, a wholesaler or manufacturer manages the onsite inventory at a supermarket distribution centre.

Ensuring an adequate supply is the name of the game. Thus, it’s a proactive approach that eliminates the possibility of missteps in reactive supply.

As a food supplier, instead of your retailer sending you purchase orders, you’ll generate your own replenishment orders based on up-to-date data and the associated KPIs.

The KPIs will be agreed with the retailer and managed in your service level agreement (or SLA). Once they’re defined, you’ll need to pay close attention to them and adhere to the conditions set forth.

Every item, inventory point, and product category will have a minimum service level and, naturally, a shelf-life expectation before they’re taken from sale.

You’ll likely incur a penalty if you fail to meet the requirements, as the retailer strives to offer the end customer the freshest products with the best possible availability.

Your contract should stipulate that the required data, such as inventory levels, sales figures, and expected consumption patterns (forecasts), are given to you on time and with accuracy. Thus, the agreement becomes a mutually beneficial partnership.

The many faces of VMI

VMI has multiple facets. The form your chosen process takes will direct the strategy you must follow.

The legal ownership is one of the most important questions to ask.

So, who owns the items in stock? You (the supplier) or the retailer? At what point does this transfer from one to the other? If it occurs when a product is taken from stock by the retailer, it’s called consignment.

Another factor to consider is the frequency of replenishment deliveries. Are there fixed time slots, or are you given more freedom?

Bear in mind, too, that the manner of replenishment might vary. Will you need to deliver directly to the distribution centre’s doorstep? Or will you need to deliver the items to the local branch or even the end customer? You might be responsible for taking the stock to the shelves.

Because of these variables, exchanging information is one of the most essential contributors to success in a VMI model. The more informed both parties are, the higher the likelihood of prosperity.

A point of consideration on this front is whether you can get real-time insights into inventory or rely on occasional updates. Are you relying on monthly forecasts, or can you access detailed Point of Sale (POS) data to build your picture of future demand?

Information is powerful in a VMI model, especially when it considers your products and the consumers who buy them.

The eradication of safety stock

From a supply chain perspective, VMI is a brilliant concept. You can remove a link from your supply chain and further eliminate uncertainty.

Think about not needing to maintain safety stock. Think about eradicating unexpected orders that land on your doorstep—the benefit of calculating orders yourself and removing the bullwhip effect.

You’ll be able to manage your supply chain costs better and balance replenishment order costs against production and transportation costs.

There are also many benefits for retailers of VMI. The planning workload can be reduced, fewer managers are needed in the inventory planning team, and with fewer stockouts, their inventory is better managed.

It’s not all positive, however, and VMI might present new challenges for you in that the reduced planning burden doesn’t lighten your workload. It can be challenging to manage the inventories at the locations of multiple retailers.

There are varying sales levels to consider, along with individual promotions, the impact of disruptions to multiple sites and differing vendor characteristics.

This is the trade-off to consider. Do you have the technology to support your move to a VMI model? Do you have the capability in-house?

If you can pursue a VMI model, the benefits make the move worthwhile. The increased commercial opportunities are there to be seized, but only if you can manage the added difficulties.

The efficiency with which you manage your supply chain will either make or break the decision to move to a VMI model for your business. Superb inventory management means combining processes, systems, and people effectively. You can lower your costs and generate far higher revenue if done well.

But you need to be careful.

Here are six tips to help you on the path to VMI success.

Slimstock has seen some great success within the Food industry. The advice below is based on our 30+ years of experience helping suppliers through this transformation journey.

Tip 1: Set realistic goals

‘On time, in full’ is the mecca for order replenishment. But there’s far more to VMI than that. The retailer you work with will set KPIs and regularly analyse your success. Because you’ve taken on accountability, you’ll need to show you’ve delivered.

No one likes a partner who overpromises and underdelivers, and that’s certainly true in a VMI model.

The most important KPI is the service level.

You must show how often a product is in stock at the right time.

Retailers may set this percentage as high as they possibly can. But you’ll need to keep a close eye on your costs. What risk lies in shrinkage? And how much inventory will you need to hold to facilitate the agreement?

We recommend analysing all your costs before agreeing to anything. It’s far better to take your time over the initial agreement before reneging on a deal, breaking a KPI or shutting down VMI entirely later because you’ve been too trigger-happy.

Not being able to meet your margins will impact you and the retailer.

Tip 2: Ensure you have the correct data

In a VMI model, the data isn’t yours. It’s on a system managed by another business that you’ll need access to. How can you get this data? And how often?

Can you access every data point you need to manage the operation successfully? Can you seamlessly link this data into your own IT systems and avoid bottlenecks?

With different inventory locations, you need to view current inventory levels, pipeline and store/customer allocation at the drop of a hat.

Even smaller considerations, like differing item codes, might play havoc with your ability to succeed. Communication is key, like most elements of the supply chain. With seamless data exchange, you should be set.

The way to know whether that’s possible is to test it before officially starting.

Tip 3: Elevate your forecasting capabilities

Reliable forecasts are the foundation of a successful supply chain. They are non-negotiable in achieving the perfect supply and optimum inventory levels.

To have a reliable forecast, you need a good process.

For a good process, you need the best systems available. Software systems with impressive statistical forecasting methods and AI techniques are now available to help you arrive at more accurate forecasts.

Obviously, with VMI, the data you rely on is from the retailer. So, the above tip becomes even more critical.

Tip 4: Automate your replenishment process

Automation can be a massive differentiator in the VMI model. Good forecasting helps. However, understanding the optimal replenishment orders for different items and inventory locations is complicated.

Your decision-making process could make the difference between profit and loss. Tech can help, especially AI and automation.

How do you manage the small decisions you’ll need for every retailer in a spreadsheet? Can you justify the manual labour involved in minimising costs for delivery loads, times, and shelf lives?

AI can make these decisions for you based on criteria you set. It’s about setting up a dynamic supply chain planning system that can monitor your KPIs and support your management, not drain its time.

Tip 5: Anticipate operational constraints

The more you replenish, the higher your costs. The perfect inventory levels must balance the result and the cost of achieving that result.

It’s not simply a case of free access to your distribution centres. You must consider that they’re operational businesses; every delivery likely disrupts their working day. Communication over your plans is paramount as they manage the time slots open to you.

There are also very often delays in the booking or storing the goods you supply. Your excellent time management is one thing, but you don’t manage the operational team at your customer.

An integrated approach to supply chain planning is critical to managing VMI.

Tip 6: Don’t expect miracles and keep improving

Continuous improvement should always be a constant consideration in your supply chain. That’s no different for VMI. Yes, it’s an incredible option for many businesses, especially in the Food industry. But it’s not a silver bullet that will solve all your woes.

There’s a learning curve to VMI.

Your team might be performing new tasks they’ve never done before or working in a new way or a new team.

Do performance goals make sense as you keep track of everything in your power? Managing expectations is a must for your business and the businesses you supply.

We often suggest conducting a pilot scheme and learning with your customer to align expectations for the real thing. Regular meetings will help you rectify discrepancies and manage the VMI process succinctly.

This will ensure your customers consider you a strategic partner they need to keep around rather than a supplier who tests new strategies for their own benefit and at their expense.

Vendor managed inventory FAQs

What is Vendor Managed Inventory (VMI), and why is it important?

Vendor Managed Inventory (VMI) is when a supplier manages the inventory at their customer’s location, ensuring timely replenishment based on agreed-upon metrics. VMI is important as it reduces stockouts, streamlines supply chains, and fosters closer collaboration between suppliers and retailers.

How does VMI benefit both suppliers and retailers in the food industry?

VMI benefits suppliers and retailers in the food industry by improving inventory accuracy, reducing stockouts and overstock, and enhancing supply chain efficiency.

What are the primary considerations for implementing VMI successfully?

The primary considerations for implementing VMI successfully include clear communication, access to accurate and timely data, alignment of goals and expectations between suppliers and retailers, effective forecasting, and adapting to changing market conditions.

What are the potential challenges or pitfalls of adopting a VMI model?

Potential challenges or pitfalls of adopting a VMI model include data synchronization issues, resistance to change from either party, difficulty in establishing trust and collaboration, increased complexity in logistics and inventory management, and the risk of over-reliance on technology.

What are the key differences between traditional inventory management and VMI?

The key differences between traditional inventory management and VMI lie in inventory ownership (with VMI often transferring ownership to the supplier until goods are sold), the proactive nature of replenishment in VMI, and the emphasis on collaborative planning and information sharing between suppliers and retailers.