Various challenges have been thrust upon distribution businesses of late, and there’s little sign of this stopping in the near future. In this exclusive interview, Torque Magazine’s Jonathon Harker speaks with Ciaran Lumsden, Business Development Manager at Slimstock, about how technology, people, and processes have to work in harmony to deliver any form of supply chain success.

The frailty of the supply chain has been brought into focus in the last few years and now there’s the ongoing situation in the Red Sea… have you seen more awareness of potential supply chain issues among customers over the last few years?

As new disruptions emerge, people need more help than ever to navigate these sorts of challenges. It’s not that a single instance of something has happened, but rather it’s an accumulation of things that have occurred over many years.

We talk about two types of volatility: there’s supply side volatility, like the Red Sea situation, and demand side. We started with Brexit, then there were product shortages, container price fluctuations, and container availability issues. All of these contributed to long lead times.

For most people, the idea of returning to normal seems like wishful thinking. Instead, ongoing supply chain challenges highlight the crucial role of companies like Slimstock. In this context, adaptability and resilience are key.

And it’s not just these events, there’s also things like legislation, the Russian sanctions, CBAM, for companies to deal with…And it’s not just these events, there’s also things like legislation, the Russian sanctions, CBAM, for companies to deal with…

No company can predict these things, but what we try to do is give customers as much visibility and agility as possible. So, when something does occur, they can react quickly to mitigate the risk as much as possible.

Reshoring and onshoring are seen as ways to mitigate these challenges. Does that kind of solution fit with what Slimstock does?

It’s going back to that point about visibility and the simulation of what could happen if you change how your supply chain works. Companies must be able to quickly explore the impact of reshoring, onshoring, or offshoring. For example, how will this impact the lead time? What about the impact on costs?

This is linked to the demand side challenges, where the increase in cost of living, wages, consumer spending and inflation means that consumers are more aware of price changes. So, if you decide to onshore and your prices increase, will you see a reduction in demand, which then means it’s not worth it? Do you take a hit on your own margin, which is already under pressure from inflation?

It’s a hard balance for businesses to strike. But for our customers, we help weigh up the best course of action to deliver their business goals.

Can you just give us an overview for people who may not be aware of Slimstock and what it can do?

Slimstock celebrated its 30th year last year. As a privately owned business, we are driven by a passion to help businesses create more agile and resilient supply chains. Our primary focus is onsupply chain planning and S&OP.

Today, we support over 1,500 customers across the world to make better supply chain decisions. As a global operation, we offer the scale and expertise to deliver combined with local intimacy that ensures local teams work with local people. For this reason, we successfully deliver 150+ digital supply chain transformations every year with customers across every industry ranging from privately-owned companies to Fortune 500 organizations.

Each industry has its nuances, but great supply chain principles are universal. We also see common challenges across all sectors: Are they challenged by volatile lead times? Are they impacted by disruptive supply chain events? Is the complexity increased to a point where spreadsheets create more problems than they resolve?

We are here to help these businesses navigate their supply chain challenges and deliver tangible performance improvements. This is both in terms of customer experience and profitability but also sustainability and eliminating all forms of waste.

We achieve this by empowering people and processes throughout the supply chain with our AI-powered supply chain planning platform. But we are far more than just a technology company. We believe in equipping supply chain teams and business leaders with the knowledge, insight, and visibility to make informed, data-driven decisions.

We do that through things like our Slimstock Academy, which offers a range of courses and development programmes to upskill supply chain teams. We also look at how a business’s process works. Can it be improved? What can we automate? And where can we fine-tune supply chain workflows?

It is a fundamental belief at Slimstock that technology, people, and processes have to work together for any form of supply chain success.

Our customers include wholesalers, retailers and manufacturers. By developing our platform in close collaboration with our customers, we go to great lengths to ensure they benefit from the latest supply chain innovations. Some of your readers might know of Toolstream or Cromwell Tools, which have been customers of Slimstock for some time.

In what ways can Slimstock help businesses?

Our approach centres on efficiency. By automating the automatable and forecasting predictable events, we can help planning teams free up time to tackle unexpected challenges like sudden spikes in demand. More importantly, by minimising mundane work, we can eliminate firefighting so our customers can dedicate more energy to delivering strategic goals.

From a workload perspective, customers see around a 50-80% reduction the planning workload. By automating routine supply chain workflows, our platform does a huge amount of the heavy lifting.

Our system automates a range of workflows, such as detecting seasonal patterns, using machine learning to understand customer behaviour and catch any unusual activity, and autonomously optimising stock levels. Our customers love it because it lets them focus on what really matters.

Reliability of supply is a big thing in the fastener industry, including being able to deliver for projects to avoid delays, etc. Is that something Slimstock is primed to help with?

Availability of products ultimately makes or breaks a business, especially in this industry. Customer expectations are extremely high. After all, stockouts quickly result in costly delays. We appreciate the importance of delivering an industry-leading standard of service.

But on the other hand, fastener companies typically offer vast assortments. Therefore, working capital constraints have to be taken into account. By providing robust insights, we help businesses balance this trade off to prioritise their working capital investment in the products that matter most. Ultimately, it’s about investing money into right stock at the right time.

We’ve mentioned sustainability, and CBAM. It’s a more important factor now and more end users are demanding sustainable supply chains. So, does Slimstock have any impact on the sustainability side of things?

Looking at it from a waste and obsolete stock perspective, the benefits are clear for everyone involved. The push for sustainability resonates with businesses committed to making a positive impact, as well as those whose performance is directly influenced by minimizing obsolete stock and waste.

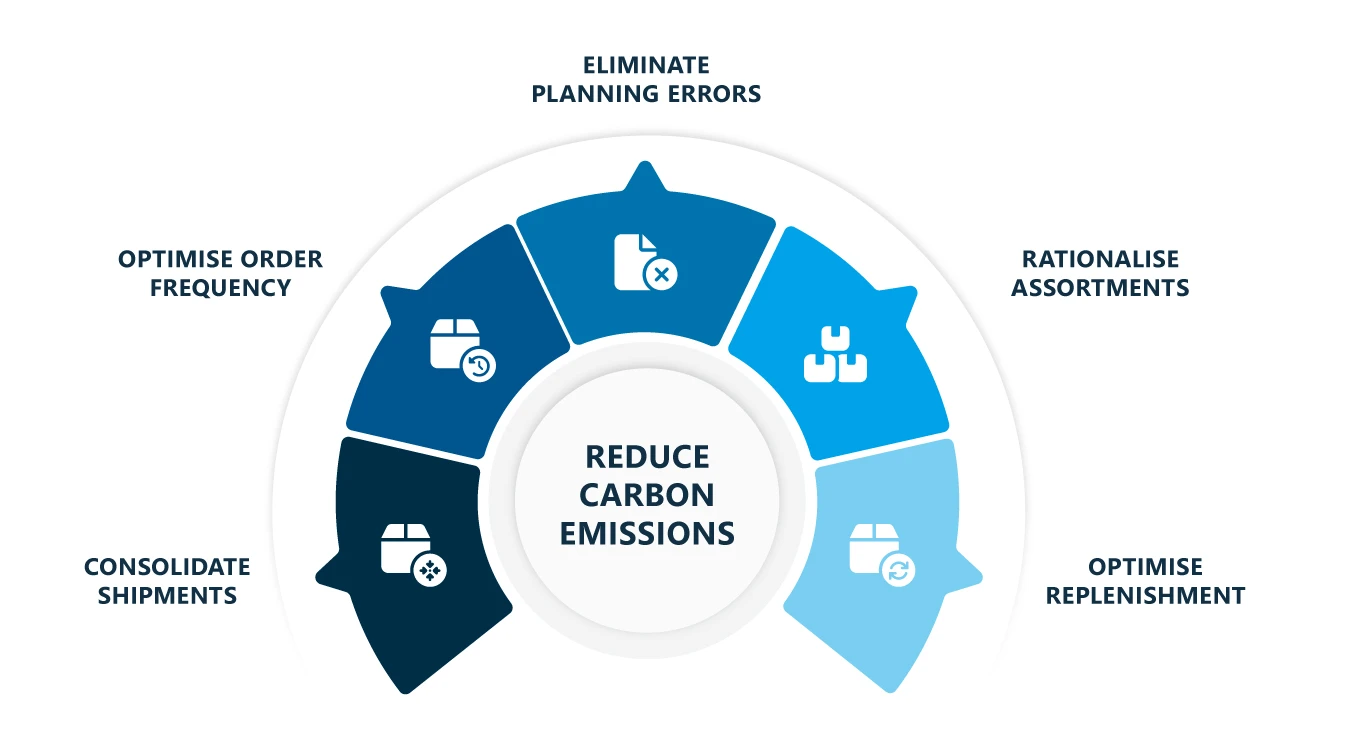

Optimising container space, for instance, allows us to consolidate orders, ensuring high availability while ultimately reducing our overall shipping frequency. Likewise, eliminating planning errors, optimising replenishment, and rationalising assortment policies all translate to a significant reduction in carbon emissions.

Of course, Slimstock is giving a seminar at Torque-Expo 2024…

We’re thrilled to attend and connect with both new and familiar faces at the event. Colin Ward, our seasoned supply chain specialist, brings decades of experience in what he would call the real world of buying things. He’ll lead the seminar, exploring how fastener companies can create greater supply chain agility.

Our goal is not only to engage in discussion with the audience but also to provide practical tips and strategies for mitigating risks associated with disruptive events.

Other than awareness of supply chain volatility, are there any big trends that you’re seeing?

I think S&OP, Sales and Operation Planning, is emerging as hot board room topic. It’s a recognition that a supply chain is not unique in a business – it shouldn’t be disconnected. Previously, I think businesses could get away with keeping supply chain management and sales and operations siloed. But we’re now in a world where everyone has to work together to ensure that we’re getting the best results possible. S&OP is something that we support our customers with. It’s part of what we do, both from a solution point of view and also from helping establish a robust S&OP process in a business.

FAQs

How does Slimstock assist businesses in navigating supply chain challenges?

Slimstock provides support through its AI-powered supply chain planning platform, offering visibility, agility, and the ability to simulate supply chain changes. By automating routine tasks and optimizing workflows, Slimstock helps businesses focus on strategic goals and adapt quickly to disruptions.

What impact does Slimstock have on improving supply chain efficiency for its customers?

Slimstock’s platform reduces planning workloads by 50-80% through automation of workflows like seasonal pattern detection, customer behavior analysis, and stock level optimization. This efficiency allows teams to allocate more energy towards strategic initiatives rather than firefighting unexpected challenges.

How does Slimstock address the reliability of product supply, particularly in industries like fasteners where project delays can be costly?

Slimstock helps businesses prioritize their working capital investment by providing insights to balance assortment sizes with working capital constraints. This ensures high product availability while managing stockouts and avoiding project delays.

What role does Slimstock play in promoting sustainability within supply chains?

Slimstock contributes to sustainability efforts by minimizing waste and obsolete stock through optimized container space, reduced shipping frequency, and efficient replenishment and assortment policies. This results in lower carbon emissions and aligns with the growing demand for sustainable practices in supply chains.

How does Slimstock support businesses in adapting to emerging trends like Sales and Operation Planning (S&OP)?

Slimstock recognizes the importance of S&OP in integrating supply chain management with overall business strategy. By providing S&OP solutions and helping establish robust processes, Slimstock ensures that supply chain decisions are aligned with broader business objectives, enhancing efficiency and performance.