Speak to one of our experts

Book a 1-2-1 demo

Manage, link, and share planning data across the extended supply chain

Optimise stock levels without risking customer availability and loyalty, through intelligent, data-driven supply planning.

From automated order proposals to dynamic safety stock calculations

Slim4 provides order advice calculations to determine optimal order quantities per product, factoring in minimum order quantities, lead times, and supplier conditions.

Advanced purchase order planning

Plan and place orders for each location based on their specific needs, while also grouping and shipping products to minimise costs and boost efficiencies.

Prioritise orders based on real-time trends

Automatically fill orders according to known, real-time supplier constraints, while prioritising items that are needed more urgently.

Thrive in a multi-echelon environment

Determine where inventory should be placed and how to manage overstock situations, by balancing the network effectively from the point of supply.

Build supplier profiles into the system

Slim4 enables you to better manage disruptions in the supply chain by setting up profiles with specific rules and closure types, so goods are ordered and shipped to cater for that dynamic.

Set your own rules and limitations

Allocation templates allow for the setup of rules and limitations when making purchase orders, ensuring efficient distribution based on configured, tailored instructions.

Optimise promotions in every location

Commercially distribute forecasts across all locations, taking into account the specific rules, demands, and trends of each store.

Slim4’s automated approach to supply planning removes human input and error from a process that has the potential to limit stockouts, enhance customer satisfaction, improve sales performance, and grow your business.

By using demand-driven order advice, Slim4 reduces unnecessary purchases, prevents order delays, and manages the full multi-echelon landscape, to optimise value across the whole process.

A common pain point for purchasers is having to respond to supplier constraints with manual adjustments. Slim4 automatically integrates those constraints, allowing you to manage balance holding, disruptions, closures, stock level adjustments, and consolidations with ease.

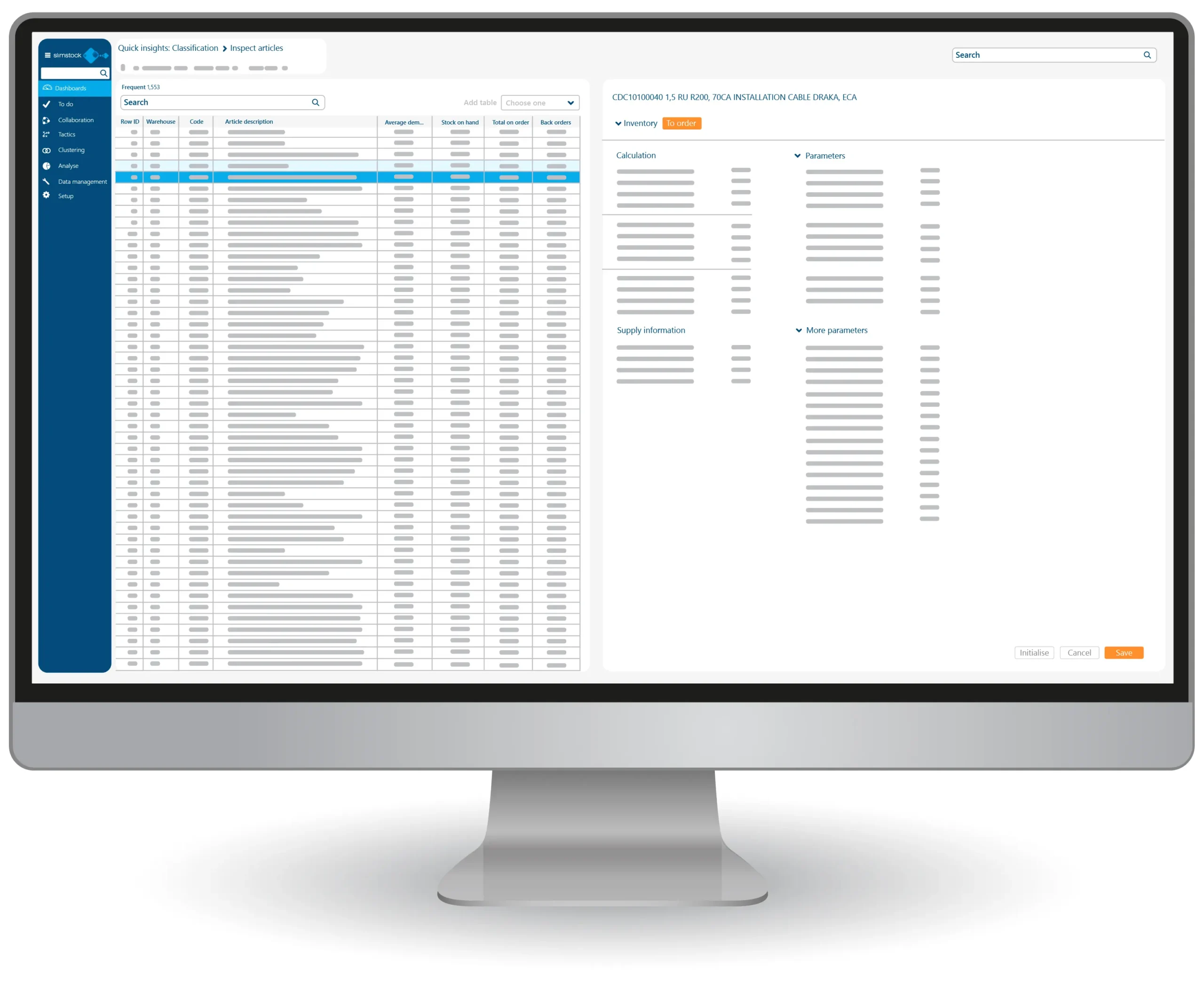

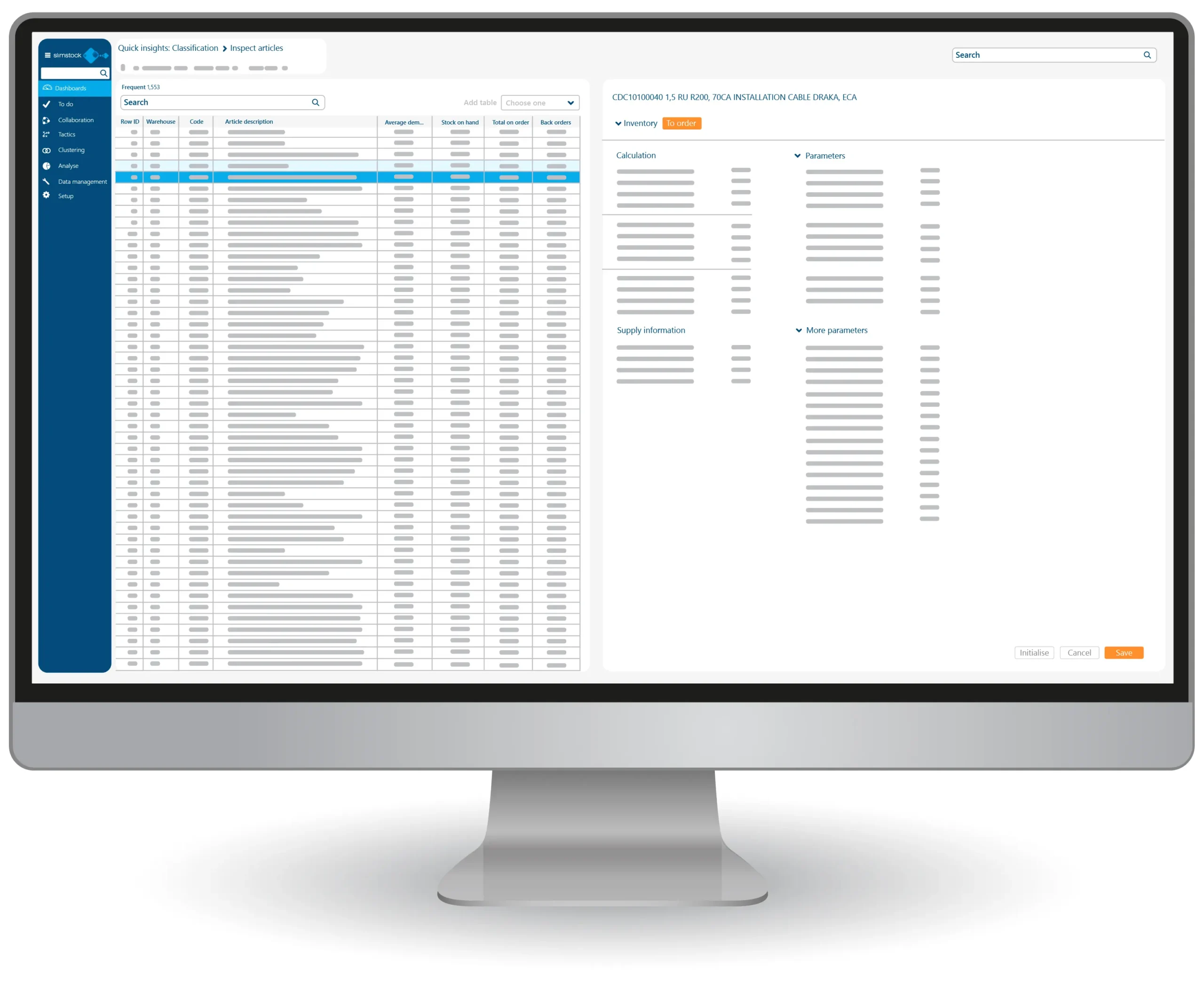

Slim4’s intuitive interface and user-friendly dashboards are an initial gateway to saved expenditure, seamless integration, and reduced downtime. Moreover, the supply planning solution is designed to scale with your business, with multi-echelon planning built for evolving needs, and expanding footprints.

Supply planning software helps keep supply and demand aligned by creating a responsive and data-driven supply chain. It ensures that changes in demand automatically adjust the supply plan and supports a service-level-driven approach to inventory.

Supply chain planning covers a wider scope, including assortment, production, promotions, collaboration and budget control. Supply planning focuses more specifically on ensuring the right stock is available at the right time, managing supplier constraints, balancing inventories across locations and automating order creation.

Slim4 is used to automate manual processes such as order creation, adjust orders to supplier constraints and manage multi-echelon environments. It highlights overstocked or understocked items, recalculates supply plans when demand changes and keeps inventory aligned with service-level goals.

It helps solve issues such as:

Key benefits include reducing overstocks and stockouts, lowering procurement complexity and costs, improving stock balancing across the network and making it easier to manage supplier disruptions or closures.

Slim4 works from a single source of truth integrated with the ERP. All supply chain data flows into Slim4, removing outdated or scattered information and supporting reliable planning across locations.

Book a 1-2-1 demo