Speak to one of our experts

Book a 1-2-1 demo

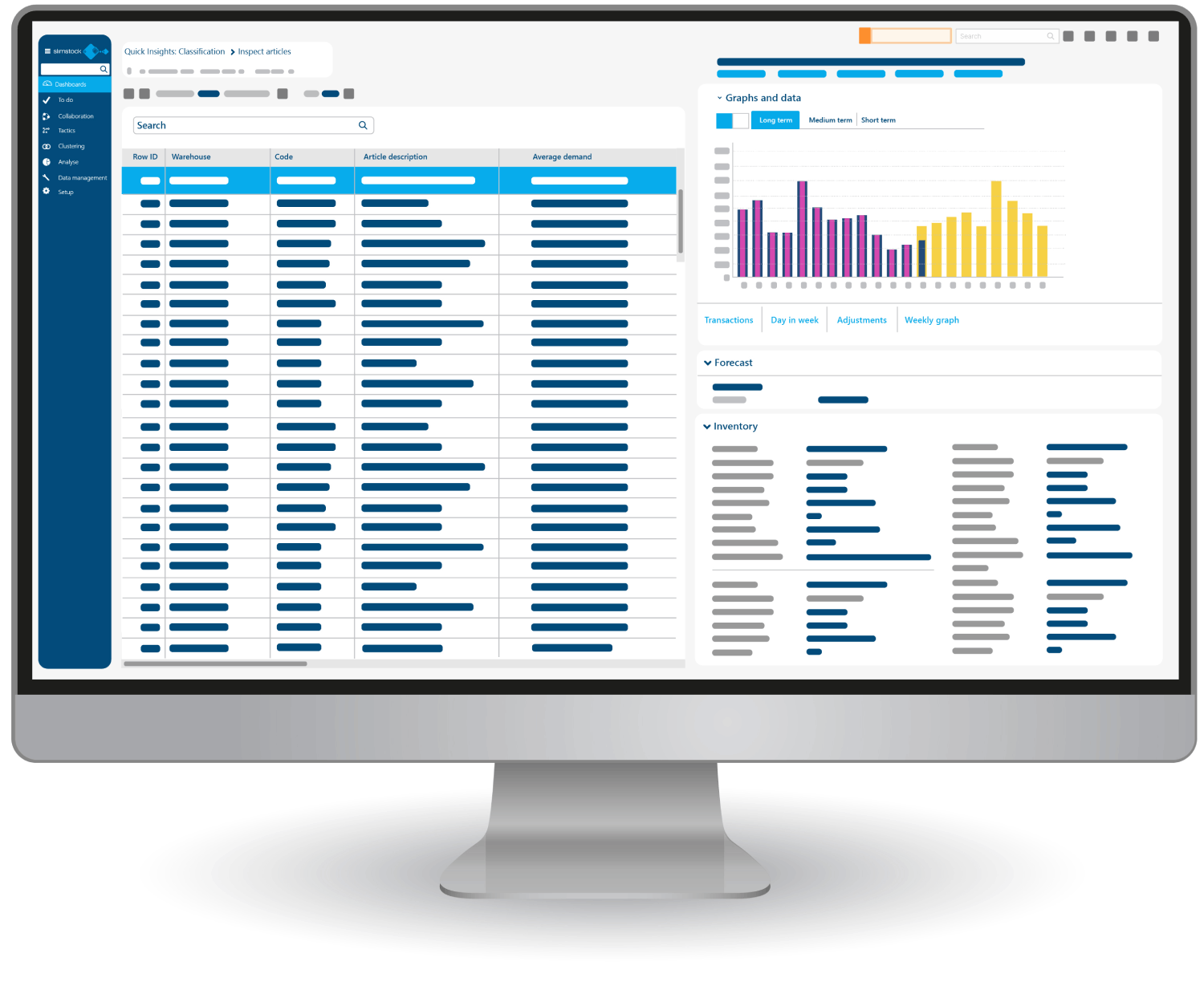

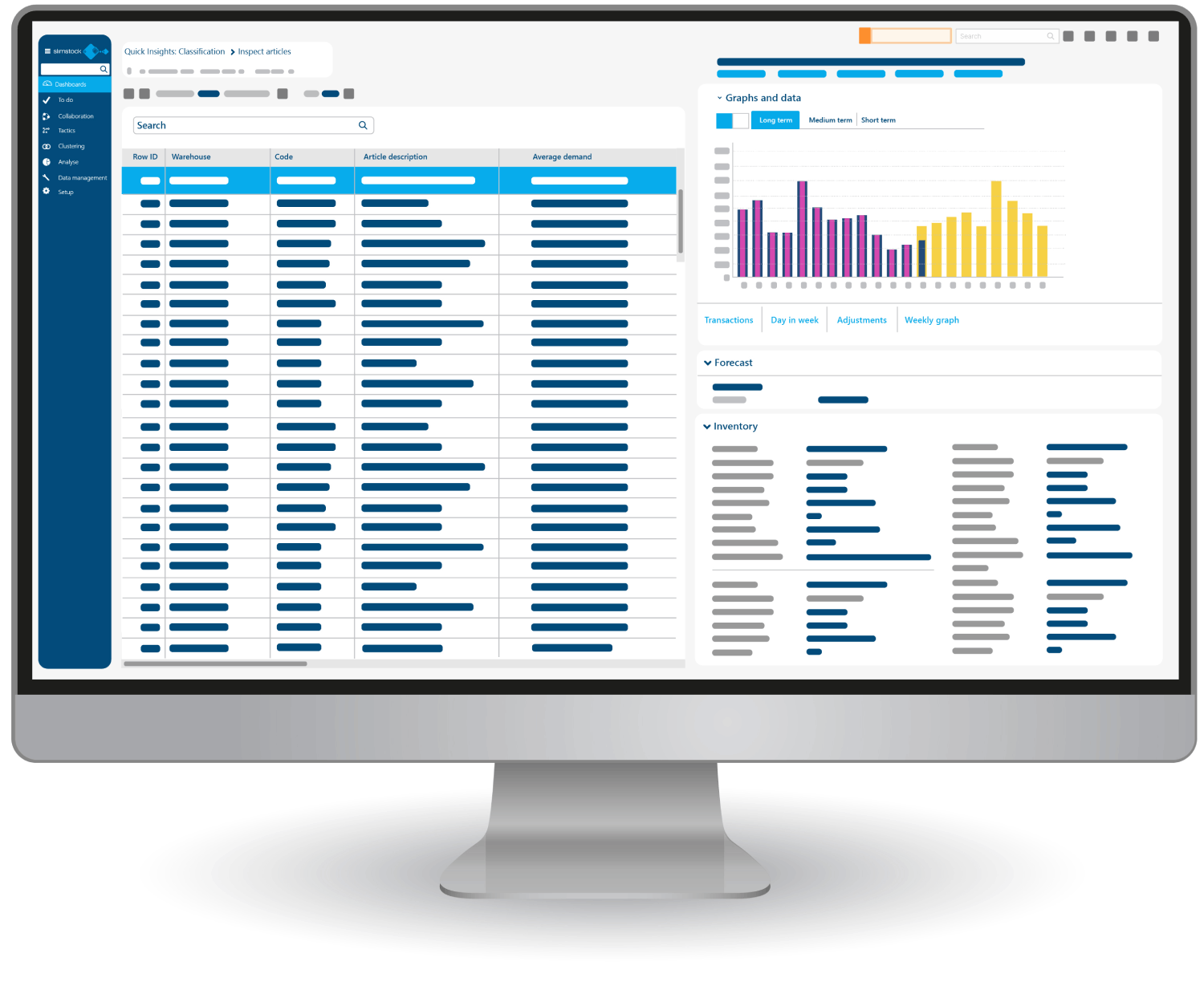

Prepare for every possibility, and optimise every strategy

Be proactive to opportunities and risks by allowing your unified supply chain data to create ‘what-if’ simulations.

Simulate, compare, optimise

Simulate the impact of changing cover periods

You can take time through Slim4’s scenario planning function. Know how two days of inbound time affects the extent of inventory you need to hold across warehouses and stores to ensure consistent availability.

Network balancing can be optimised through effective scenario planning. Slim4 lets you know where items should be located across warehouses, stores, or perhaps they shouldn’t be stocked at all. Advanced stock policy relies on clear insight and best-case decision-making.

Multiple scenario analysis through the Slim4 platform optimises ABC classifications. Know the impacts of making any product an ‘A-item’ to maximise every sales opportunity relative to real-time demand.

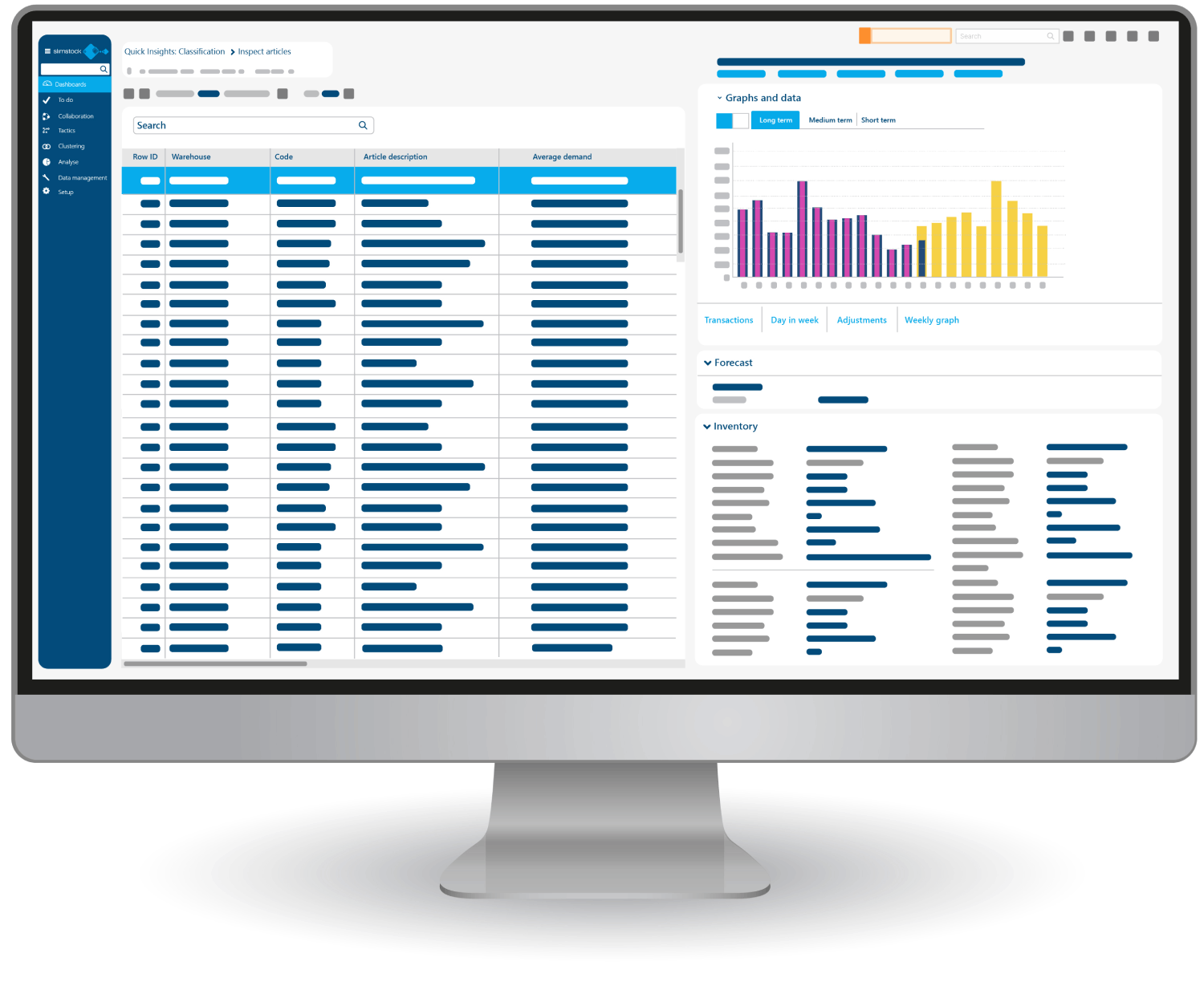

Strive for new service level performance

Simulate the impact of changing your service levels relative to buffer stock, average stock, days on hand, lost sales, order levels, and order lines. Gain insight into your current weighted service level against real-time targets, and potential future scaling.

By seeing what might happen through multiple lenses and scenarios, you will be better placed to make the right decision for your business across multiple time horizons. Adjust inventory with confidence for real-time optimisation, while also altering longer-term plans for sustainable business growth.

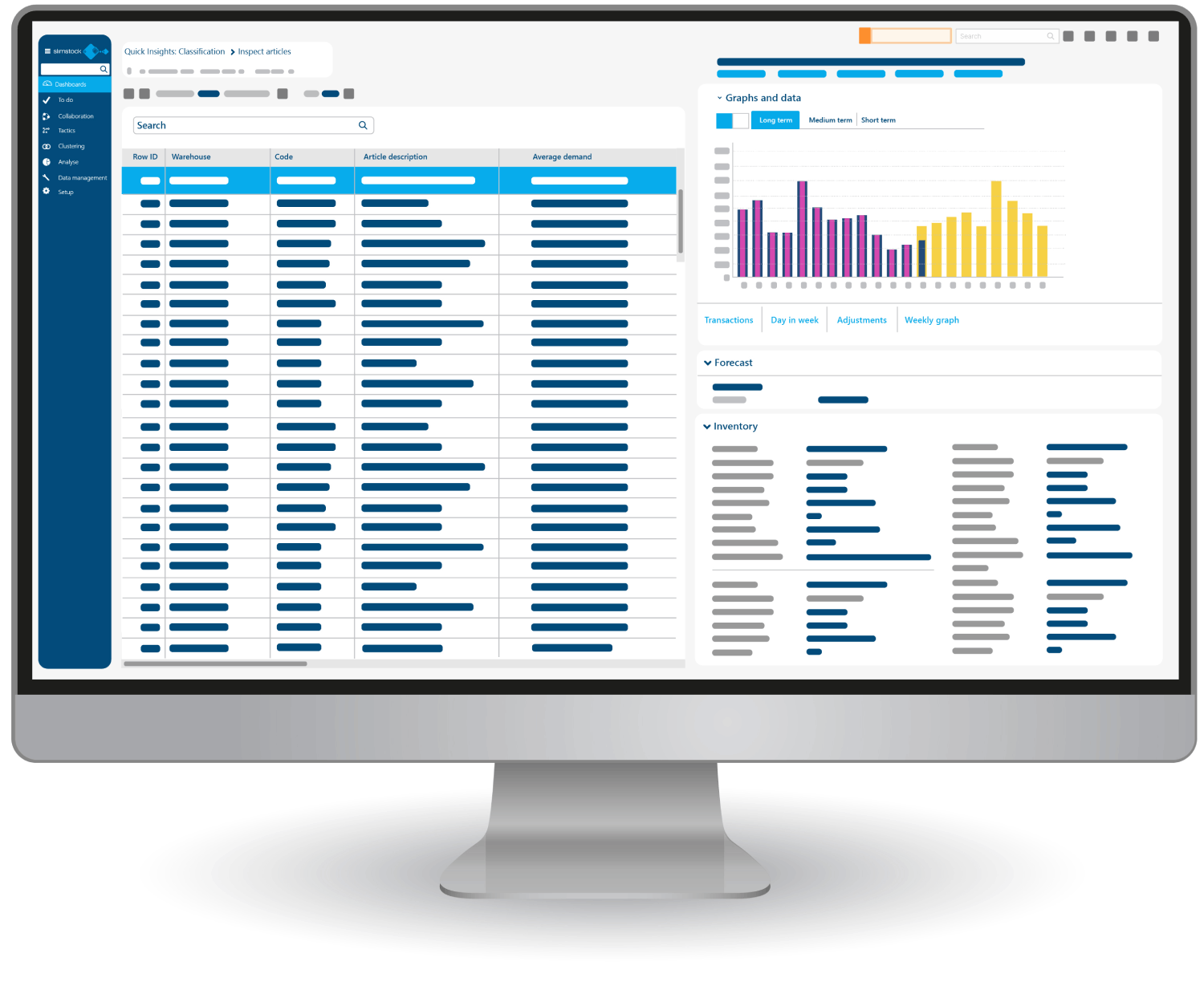

Optimising operations has always come from being as informed as possible. With data-driven insight and Slim4’s scenario planning function, every decision relating to inventory, rule changes, stock policy, capital, machines, labour, and logistics is made with statistical surety.

All inbound supply decisions can be made from not only cross-functional data exploring demand and inventory capacity, but also through various what-if scenarios that confirm the impacts of different decisions. Set a strong precedent for efficiency and maximised value through these initial supply decisions.

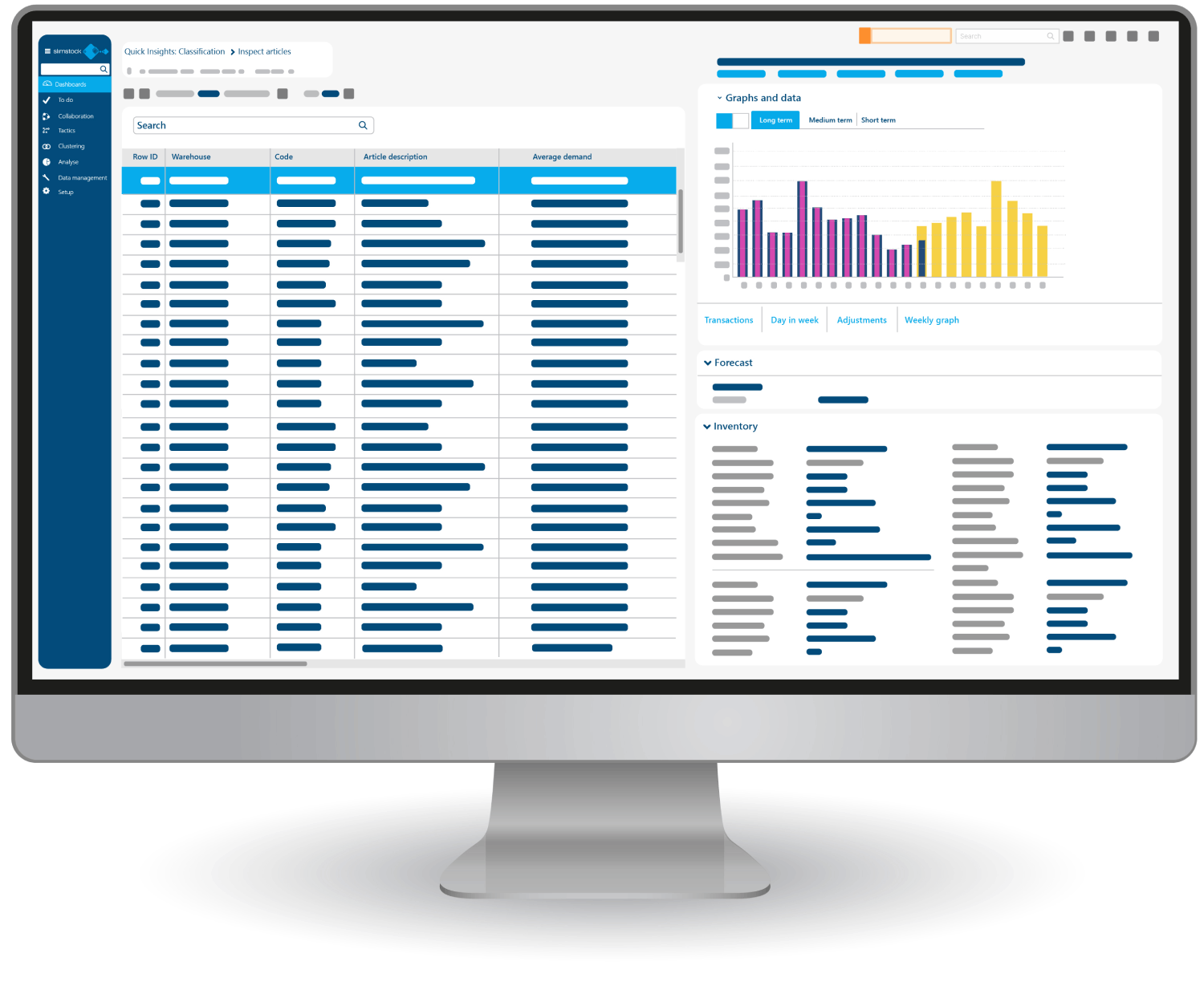

Scenario planning software helps businesses explore different “future state” situations by modelling how changes in demand, strategy or external events could affect their supply chain. It provides a structured way to test assumptions, assess risks and prepare response strategies for uncertain or volatile conditions.

Scenario planning solution in supply chain is essential because it helps organisations understand how different choices or market shifts may impact operations. By analysing multiple scenarios, businesses can identify risks earlier, evaluate opportunities and make more confident decisions. It also strengthens resilience by preparing teams to respond quickly to disruptions.

Before selecting scenario planning software, businesses should look at:

Slim4 can model a wide range of scenarios, including:

Initiative scenarios linked to S&OP, such as new store openings or expansion plans with best-case and worst-case variations.

Book a 1-2-1 demo