From crafting unique products that stand the test of time to ensuring every aspect of its end-to-end operations satisfies its high sustainable standards, the supply chain is the backbone of ILVA’s success. However, as Denmark’s largest furniture and interior design retailer pursues further expansion, the business has taken bold steps to revolutionise its approach to supply chain planning.

Challenge & Goals

To inspire its customers to create a more vibrant home, ILVA goes to great lengths to offer the perfect combination of quality and design, all while providing exceptional value. With an ever-growing online presence and a 41-strong showroom network across Denmark and Sweden, the leading furniture retailer is renowned for its beautifully designed homeware products.

“Our goal is to set the industry standard in customer experience. This means offering the customer a unique selection of furniture with the shortest possible lead time. But we also need to achieve this as we open new stores and minimise our working capital investment in stock,” states Kim Nisted, Purchasing Manager at ILVA.

Results

With ambitious goals to expand its footprint, ILVA joined forces with the supply chain experts at Slimstock. Within just months of adopting Slimstock’s advanced supply chain planning platform, Slim4, ILVA has seen remarkable results:

- 5% increase in service levels while attaining a 25% reduction in stock

- Improved efficiency throughout the planning department

- Enhanced visibility across its end-to-end network

Why Slimstock

As ILVA’s operation expands, the planning team must make more intelligent supply chain decisions that allow the business to do more with the available resources. This is in terms of its working capital investment and the existing warehouse capacity.

Explaining the decision to partner with Slimstock, the Purchasing Manager states: “There are many plug-and-play solutions available. However, these simple tools only offer a partial solution. We needed a partner with the right knowledge and an advanced tool to help us elevate our processes. With the winning combination of Slimstock’s sophisticated best-of-breed technology and their experienced team, we were confident they were the right partner to help us create the robust planning foundation required to achieve our goals.”

Solutions

Orchestrate supply and demand

By taking advantage of Slim4’s powerful forecasting engine, the planning team at ILVA now have access to more accurate demand insights. Furthermore, by providing responsive exception-based alerts, Slim4 has helped Kim and her team focus on the areas that require it most.

Kim highlights the impact this enhanced visibility has had on the business: “In the past, our forecasts were based on very simple formulas. The Slim4 platform offers far more powerful forecasting capabilities. By enabling us to predict demand with a previously unattainable level of precision, we have increased service levels by 5% while still attaining a 25% reduction in stock. Furthermore, the exception-based alerts allow us to dive in and investigate where we need to fine-tune our business rules to drive continuous improvements.”

Improved efficiency

For the team at ILVA, it was also essential to drive operational efficiency improvements throughout the planning process. Since adopting the Slim4 platform, the planning team has had a much tighter grip on supply chain constraints.

“The Slim4 platform has proven immensely valuable for us. Previously, we depended on forecasts from ERP to plan our purchase orders. However, we often found that containers were only 2/3 full, and we would have to use gut feel to work out how to make the most of the order. With Slim4, this process is much smarter, with service levels and order parameters dynamically considered to ensure efficient ordering,” explains Kim.

Seamless collaboration

The benefits of Slim4 can be felt across the business. For example, optimised order quantities have created a more peaceful situation for the warehouse team. But more importantly, the Slim4 platform now plays a crucial role in enabling effective cross-functional collaboration.

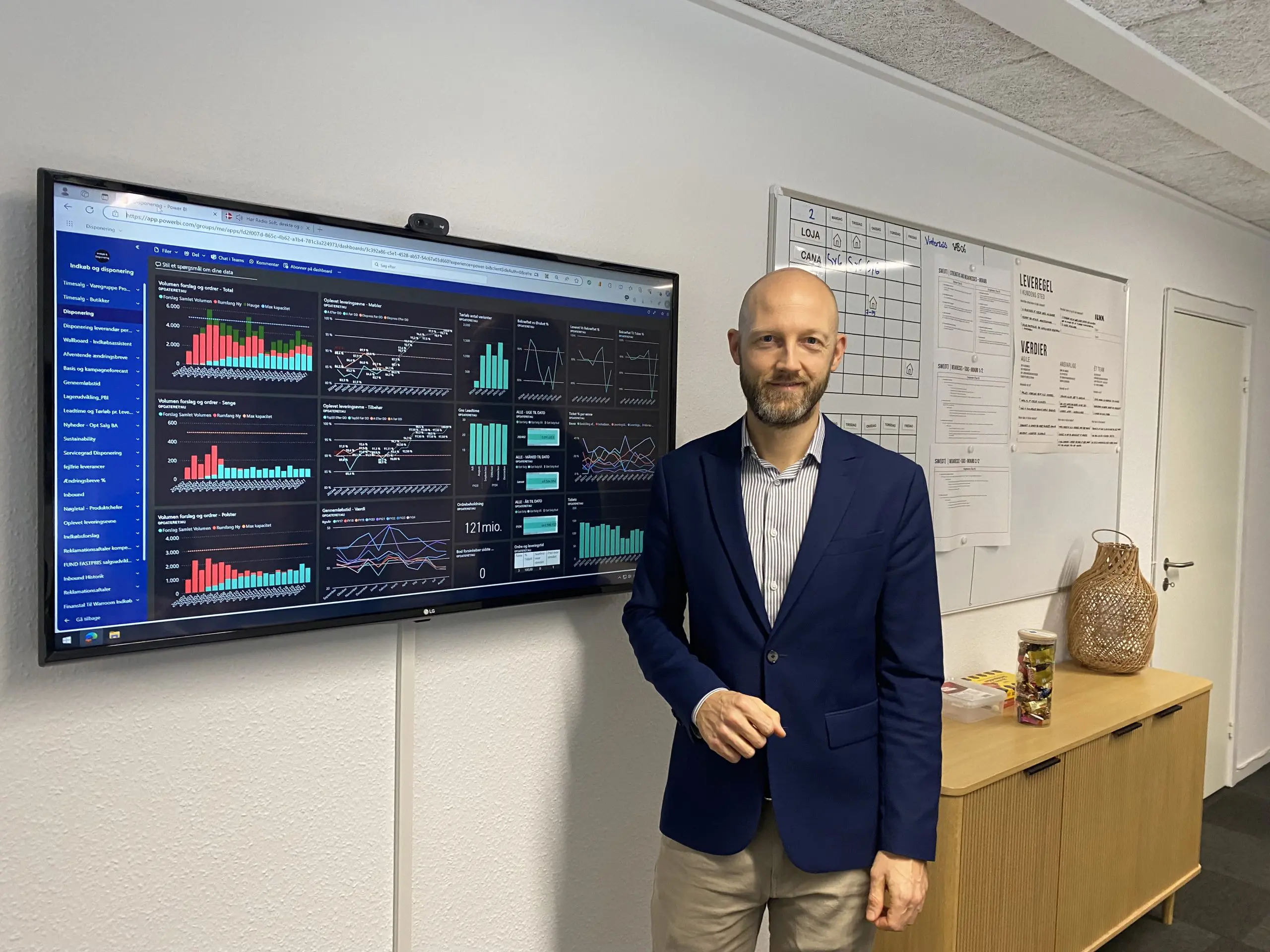

“We can now measure our progress and communicate the results throughout the organisation. But, more importantly, we can now easily visualise our KPIs to engage top-level management, ensuring our supply chain tactics align with the wider business strategy,” explains Kim.

Next Steps

Following the rapid adoption of Slim4, Kim and his team are already pursuing further performance improvements: “For example, we are developing a differentiated lead time approach with our suppliers, allowing us to leverage further operational efficiencies.”

“We have exceeded our service level and inventory reduction goals. But by providing our team with the right tools and knowledge they need to make good decisions, we have only just begun to scratch the surface of what is possible,” concludes Kim.