What is ABC Analysis?

To apply the laws of Pareto to the supply chain, we often use a clever technique called ABC Analysis. In essence, ABC inventory analysis is the process of classifying inventory by priority, based on given criteria. With the insights that this analytical approach provides, we can identify meaningful opportunities to optimise inventory levels.

This useful tool helps supply chain teams to reduce carrying cost and unlock working capital. But more importantly, a good ABC analysis should help increase sales turnover through attaining better availability on the products that matter most to the customer. As a result, businesses that take advantage of this approach run leaner and more efficiently.

When you’ve finished, your inventory will typically be divided into three core categories – A, B and C – based on strategic importance.

Category A: Products which are important and thus require tight control.

Category B: Products which are of lower importance, but even so, must be managed with a medium level of control.

Category C: Products which are of lower importance and which only require the simplest level of control.

The name “ABC” suggests that you have just 3 classes. But if you wanted, you could distinguish 10 classes. However, this could make the data a little trickier to interpret. We will explore this later.

The Pareto principle, also known as the 80/20 rule, indicates that 80% of a company’s turnover is generated by only 20% of the assortment. These are the ‘golden eggs’ and should be treated with care and attention.

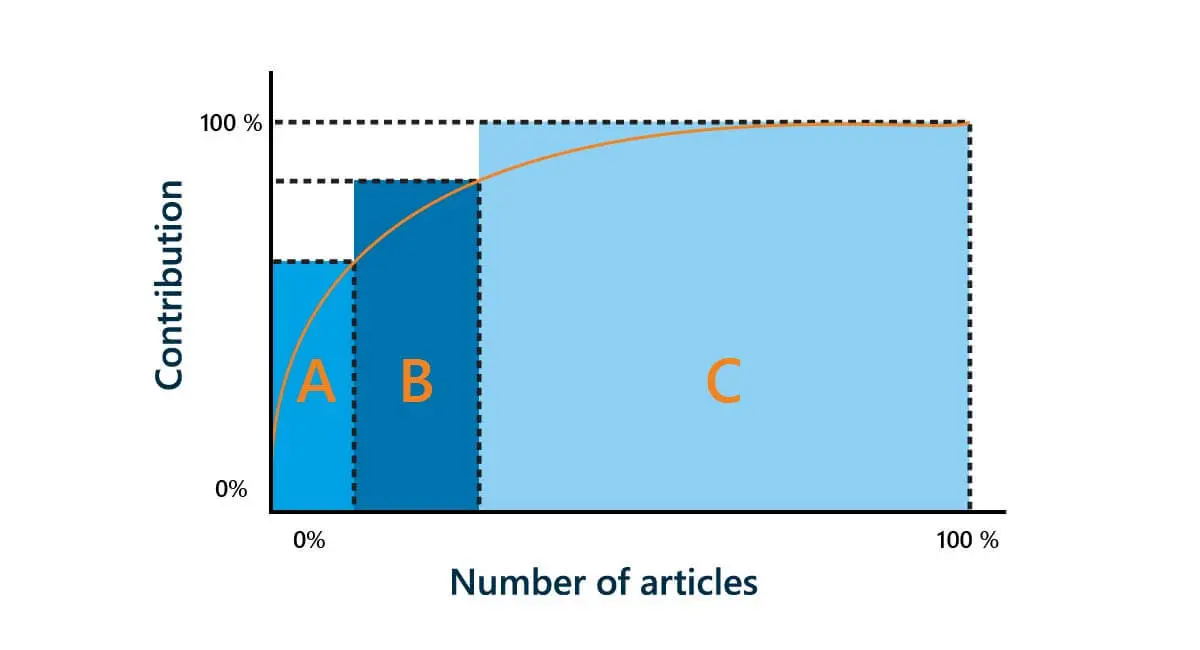

In the following example, Category A articles contribute 70% to the company’s margin, Category B articles contribute 20%, and finally Category C articles contribute 10%.

The graph below clearly shows that 70% of the articles only contribute 10% to the company’s margin. Often these Category C articles require a lot of consideration because of their volatility and the complexities around properly forecasting their future demand.

However, given that the Category A articles are the most important items to the business, they should receive proper focus and should not be neglected.

Why is it important to classify your products?

When you offer a large assortment, it is easy to get distracted by products that offer a very low contribution to your company’s profit margin. The main reason is the fact that these items often show a high volatility and are therefore difficult to manage.

The whole purpose of ABC Analysis is to logically structure your assortment and identify your priorities within it. As a result, you should benefit from greater focus. By classifying products based on their strategic importance to your business, you can ensure that you invest your time and money where it counts most.

Why should you do an ABC Analysis?

ABC analysis will provide you with a great deal of interesting insight into your assortment. This can be used to drive optimisation initiatives that are designed to save money, improve service and boost profitability.

Here are just a few examples of how your business could benefit from completing an ABC analysis:

- Changing your investment priorities to focus on Category A items, as opposed to Category C items which are not doing much for the business

- Implementing new strategies that minimise the requirement for manual intervention on unimportant products

- Refocusing your team’s attention to proactively managing important products and preventing issues before they can impact the customer or the bottom line

Ultimately, you should use this handy analysis to spend time and resources, both of which are usually in short supply, on the things that really make a difference.

What steps are involved in an ABC Analysis?

ABC analysis can be performed on a wide selection of criteria, such as your historic or forecasted figures relating to:

- Sales volume

- Cost of Goods Sold (COGS)

- Sales Turnover

- Margin

The steps required to complete an ABC analysis depend on the level of complexity and detail you wish to explore.

But first, let’s consider your goals.

What is the aim of your ABC Analysis?

The first thing the management team must do is to determine what you wish to achieve by performing an ABC analysis.

Here are a few examples:

- Is it to determine which products are important?

- Is it to determine which customers are important?

- Is it to determine what the warehouse layout should be?

The objective we are aiming for will form the basis of the ABC analysis.

Should the management team want to attain a better understanding of your assortment (#1 above), then ideally the following data will be needed:

- Margin per SKU

- Number of customers per SKU

However, should the objective be associated with warehouse layout (#3 above), then the following data will be key:

- Number of picks per SKU

- Metres squared (or cubed) per SKU

What kind of ABC Analysis is right for your business?

Now that you have determined the goals of the analysis, how complicated does your analysis need to be to achieve the desired insight?

Are you looking for a simple ABC analysis based on just one criterion? Or do you need a more detailed ABC analysis that looks at multiple factors?

For a quick and easy result that everyone can understand, it probably makes sense to go with a simple analysis. However, if you need a more granular breakdown of your assortment, you will need to dive a bit deeper.

Completing a simple ABC Analysis

Are you setting up a new warehouse and would like to know what your fast runners are so that these items can be stored in easy access locations? (Probably low down and near the front of the warehouse.) Then a simple ABC analysis identifying the number of order lines or sales turnover would suffice.

To complete this single-dimensional ABC analysis, we simply take the most important criteria and categorise the products based on the extent to which each of them contributes to the business.

More complex, multi-dimensional ABC Analysis

If your business is interested in identifying the items that also make the most money in order to help the planning team to prioritise these products, we need a multi-dimensional ABC. Sometimes, this is referred to as ABC-XYZ analysis.

For this example, we could use:

Dimension 1 = Margin

Dimension 2 = The Number of Order Lines or perhaps Sales Volume

By looking at two different dimensions we can gain a much richer insight into how each item performs on the two factors in question. For example, if a product ranks low in terms of margin but high in terms of number of customer orders, we can see that this is a key product within our assortment.

What criteria should you base your ABC analysis on?

There are lots of criteria we could use to conduct an analysis. However, it’s important that you select the criteria which best fits the goals of your analysis.

Here are just a few examples of criteria you could use and what the analysis will tell you: